Polymer-matrix composite material with super-hydrophobic surface and preparation method thereof

A technology of super-hydrophobic surface and composite materials, applied in the field of super-hydrophobic composite materials and their preparation, to achieve stable super-hydrophobic properties, improve waterproof and anti-freeze performance, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

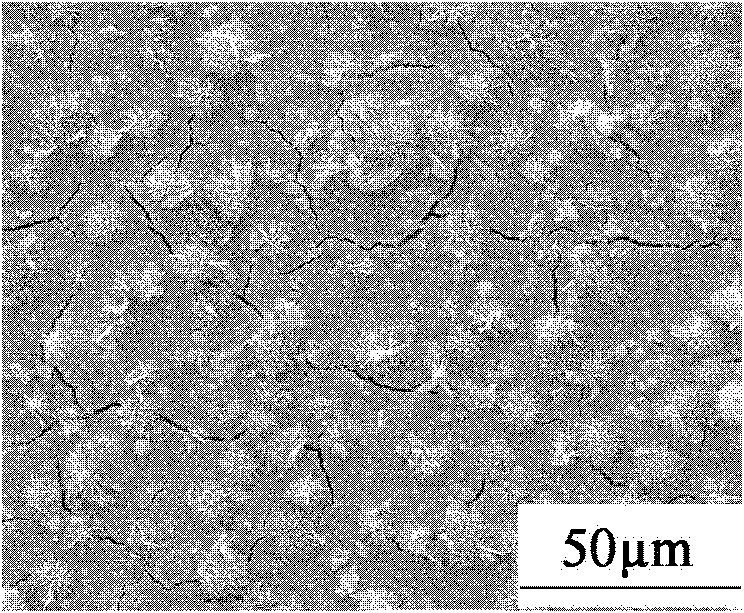

[0024] a kind of like figure 1 The polymer-based composite material with a superhydrophobic surface of the present invention shown, the polymer-based composite material includes a composite material body and a superhydrophobic coating coated on the composite material body, and the composite material body is a carbon fiber cloth reinforced epoxy resin matrix composite material, the thickness of the super-hydrophobic coating is 30 μm, and the micro-flower-like structure with a diameter of 10 μm to 30 μm is distributed on the super-hydrophobic coating (see figure 1); the matrix material of the superhydrophobic coating is epoxy resin, and the main components of the microflower-like structure are metal copper oxide nanopowder and stearic acid ethanol solution (or ethanol solution of perfluoro fatty acid or heptadecafluorotrimethoxyethylene Oxysilane ethanol solution) self-assembled mixture, the particle size of the copper oxide nanopowder is 20nm-100nm, and the average particle siz...

Embodiment 2

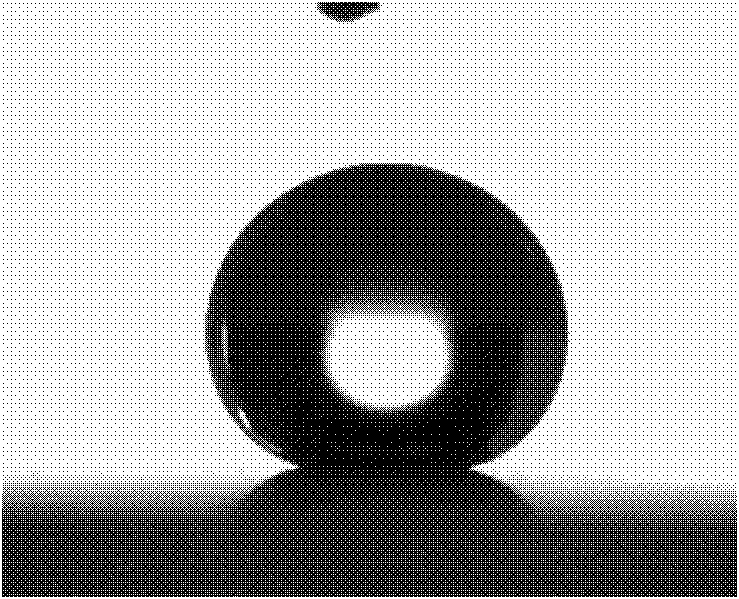

[0039] A polymer-based composite material with a superhydrophobic surface of the present invention, the polymer-based composite material includes a composite material body and a superhydrophobic coating coated on the composite material body, and the composite material body is a carbon fiber cloth reinforced epoxy resin base Composite material, the thickness of the super-hydrophobic coating is 50 μm, and the micro-flower structure with a diameter of 10 μm to 30 μm is distributed on the super-hydrophobic coating; the matrix material of the super-hydrophobic coating is epoxy resin, the main component of the micro-flower structure It is a mixture formed by self-assembly of metal copper oxide nanopowder and stearic acid ethanol solution, the particle diameter of the copper oxide nanopowder is 20nm-100nm, and the average particle diameter is about 70nm. The contact angle of this superhydrophobic coating surface and water is 155 ° ± 1.9 ° (see image 3 ), the rolling angle of water d...

Embodiment 3

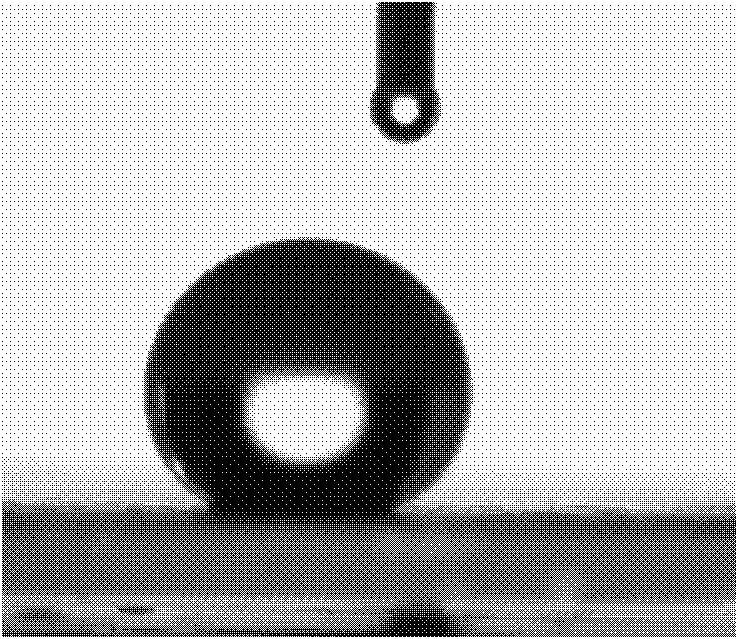

[0054] A polymer-based composite material with a superhydrophobic surface of the present invention, the polymer-based composite material includes a composite material body and a superhydrophobic coating coated on the composite material body, and the composite material body is a carbon fiber cloth reinforced epoxy resin base Composite material, the thickness of the super-hydrophobic coating is 30 μm, and the super-hydrophobic coating is distributed with a micro-flower structure with a diameter of 10 μm to 30 μm; the matrix material of the super-hydrophobic coating is epoxy resin, the main component of the micro-flower structure It is a mixture formed by the self-assembly of metal copper oxide nano powder and stearic acid ethanol solution, the particle diameter of the copper oxide nano powder is 20nm-100nm, and the average particle diameter is about 50nm. The contact angle of this superhydrophobic coating surface and water is 153 ° ± 1.7 ° (see Figure 4 ), the rolling angle of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com