Preparation method of short-cut nitrification and denitrification granular sludge in high Do condition

A technology of granular sludge and short-range nitrification, which is applied in the direction of aerobic and anaerobic process treatment, can solve the problems of aerobic granulation affecting microbial activity, and achieve the effect of good stability and compact particle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Specific steps are as follows:

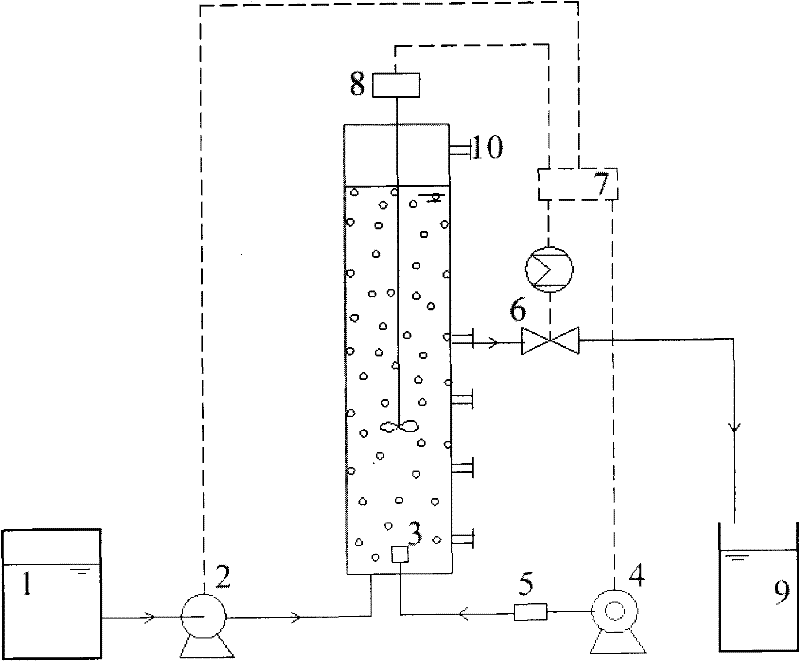

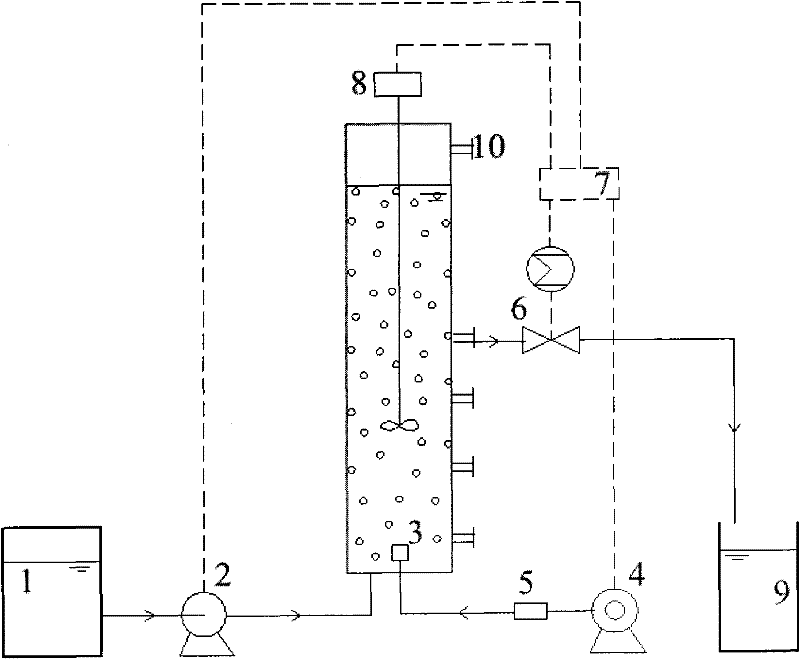

[0023] (1) The activated sludge from the unacclimated municipal wastewater treatment plant was inoculated into the sequencing batch batch reactor. The effective volume of the sequencing batch batch reactor is 3.5L, the diameter of the outer tube is 10.0cm, and the height is 55cm, such as figure 1 shown.

[0024] (2) The air enters the reactor through the air pump 4 through a microporous aeration head 3 installed in the center of the reactor bottom, and the air flow formed makes the liquid and granular sludge in the reactor evenly mixed. The water is fed into the bottom of the reactor through the peristaltic pump 2, and the water outlet is controlled by the solenoid valve 6. The outlet is at the bottom of the reactor at a height of 25 cm, the volume exchange rate is 50%, and the reactor operates at room temperature (20-30° C.).

[0025] (3) The water intake, stirring, aeration, settling and drainage time of the reactor are all automatic...

Embodiment 2

[0029] Specific steps are as follows:

[0030] (1) The short-range nitrification and denitrification granular sludge obtained from the cultivation is injected into the sequencing batch batch reactor. The effective volume of the sequencing batch batch reactor is 3.5L, the diameter of the outer tube is 10cm, and the height is 55cm.

[0031] (2) Air enters the reactor through an air pump 4 through a microporous aeration head 3 installed in the center of the reactor bottom, water enters the reactor bottom through the peristaltic pump 2, and the water is controlled by the solenoid valve 6, and the outlet is at the bottom of the reactor. At 25cm, the volume exchange rate is 50%.

[0032] (3) The water intake, stirring, aeration, settling and drainage time of the reactor are all automatically controlled by the dual time relay 7. The cycle time is 4 hours, including 6 minutes for water inflow, 4 minutes for water outlet, 1 hour for anaerobic stirring, 2 hours and 48 minutes for aera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com