Separation and purification method of high-purity glabridin

A technology for the separation and purification of glabridin, which is applied in organic chemistry and other fields, can solve the problems of difficult further improvement of product purity, low product yield, complicated operation, etc., and achieve the effects of easy quality control, high yield and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The separation and purification method of the glabridin monomer of the present embodiment is carried out according to the following process steps:

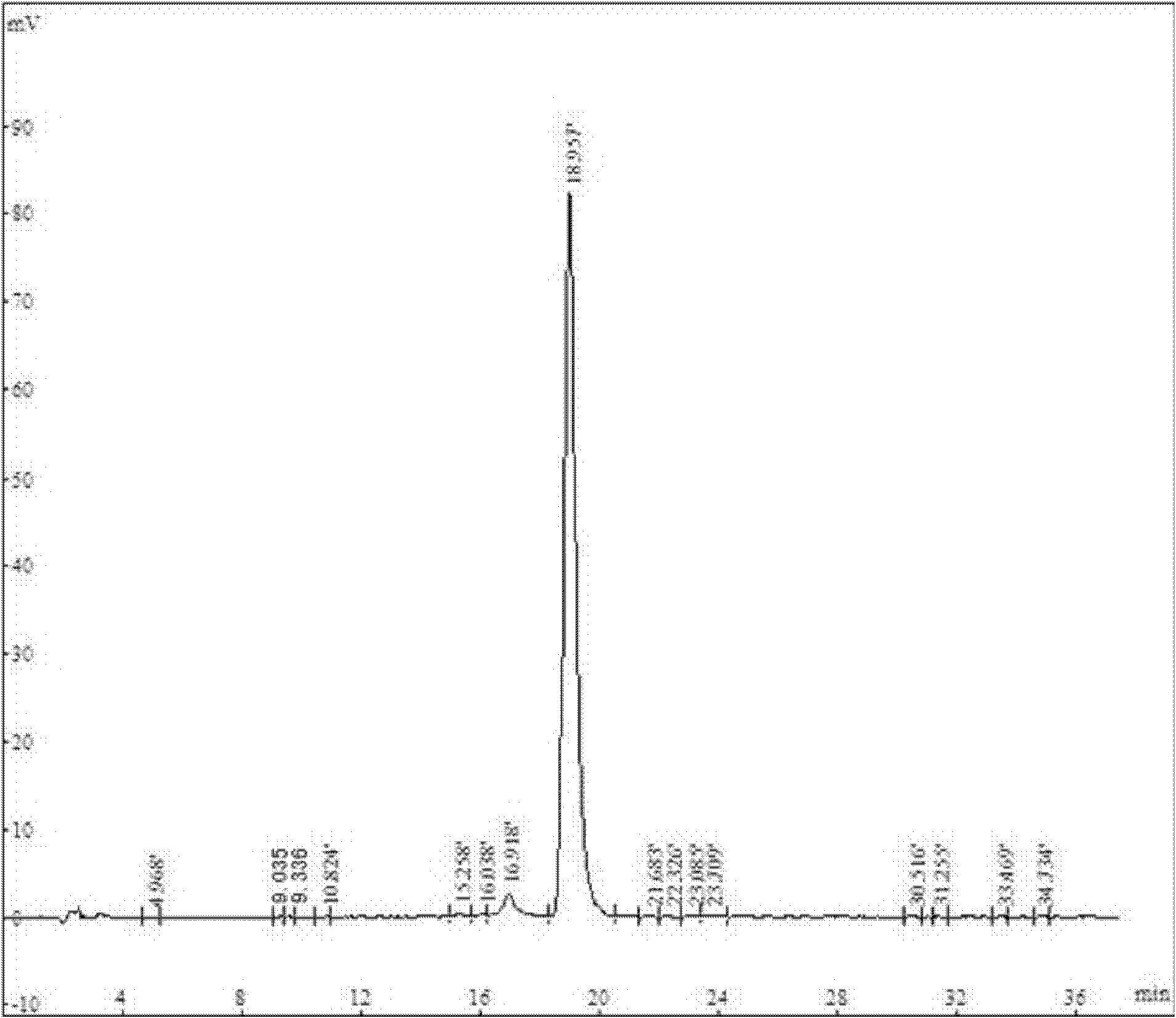

[0034](1) Extraction of effective parts: take 10KG of Glycyrrhiza glabra, add 80L of ethanol solution with a concentration of 20% by volume, heat and extract at 60°C for three times, and the extraction time is 3, 2, and 1 h respectively, and the extracts are combined, Concentrate under reduced pressure at the temperature of 40 ℃~50 ℃, recover ethanol to dryness, obtain 3L of extract material extract, HPLC detects (mobile phase: acetonitrile-water (50:50) wavelength: 292nm flow rate: 1ml / min C18 ( 250×4.6mm) injection volume: 10ul) This extract contains glabridin (see figure 1 ).

[0035] (2), enrichment of effective part and impurity removal: add equal volume of ethyl acetate to extract 3 times after the extract extract is suspended with tap water of 3 times the quality, and detect that the product has been extracted in a ...

Embodiment 2

[0040] The separation and purification method of the glabridin monomer of the present embodiment is carried out according to the following process steps:

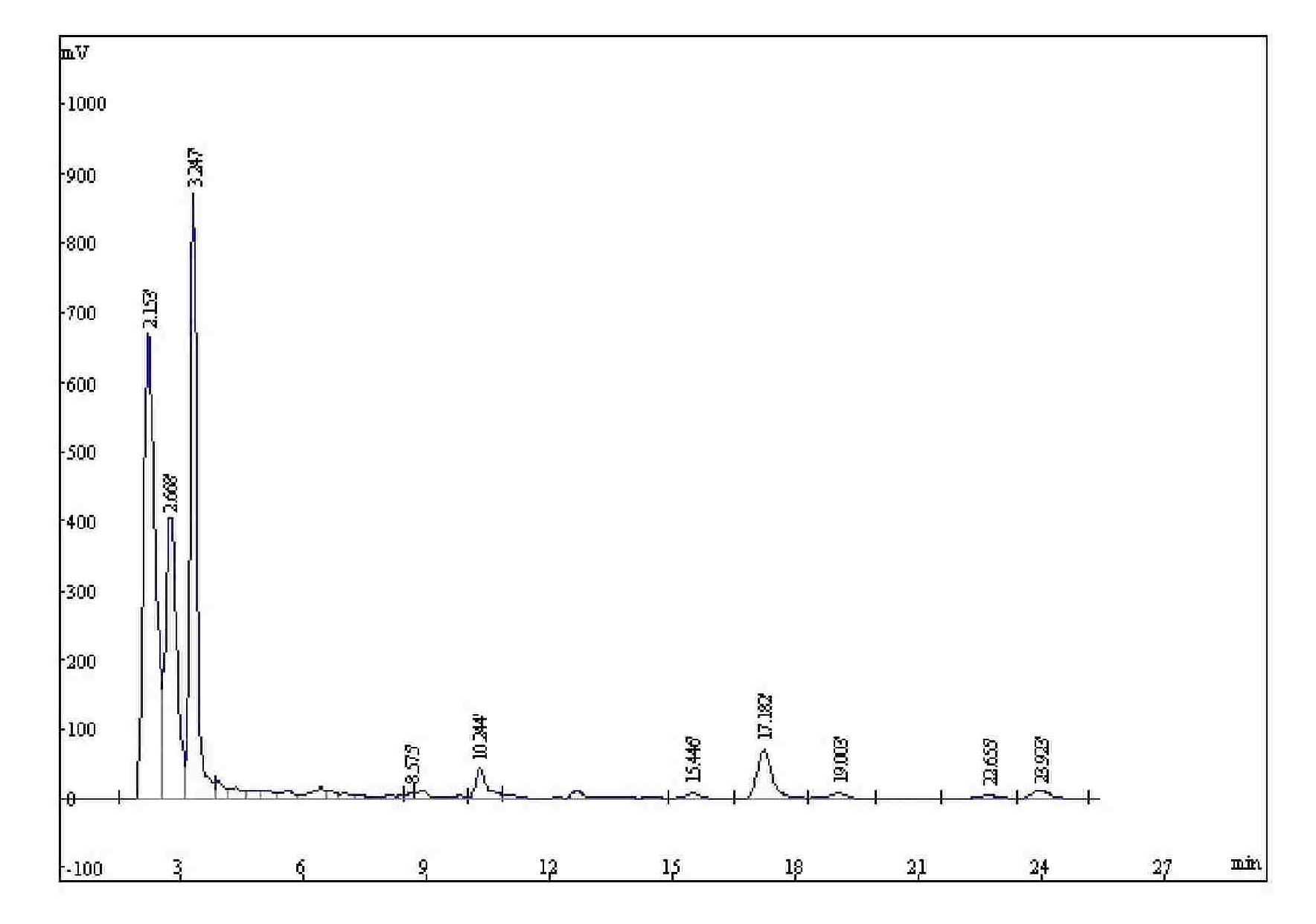

[0041] (1), extraction of effective parts: take 20KG of Glycyrrhiza glabra, add 160L of ethanol solution with a volume percentage concentration of 60%, heat and extract at 50 ° C for three times, the extraction time is respectively 3, 2, 1h, and the extracts are combined, Concentrate under reduced pressure at a temperature of 40°C to 50°C, recover ethanol to dryness, and obtain 6L of extract material, which is detected by HPLC (mobile phase: acetonitrile-water (50:50), wavelength: 292nm, flow rate: 1ml / min C18 (250×4.6mm), injection volume: 10ul) This extract contains glabridin (see figure 2 ).

[0042] (2), enrichment of effective parts and impurity removal: after the extract extract is suspended with 3 times of tap water, add an equal volume of dichloromethane for repeated extraction, and detect that the product has bee...

Embodiment 3

[0047] The separation and purification method of the glabridin monomer of the present embodiment is carried out according to the following process steps:

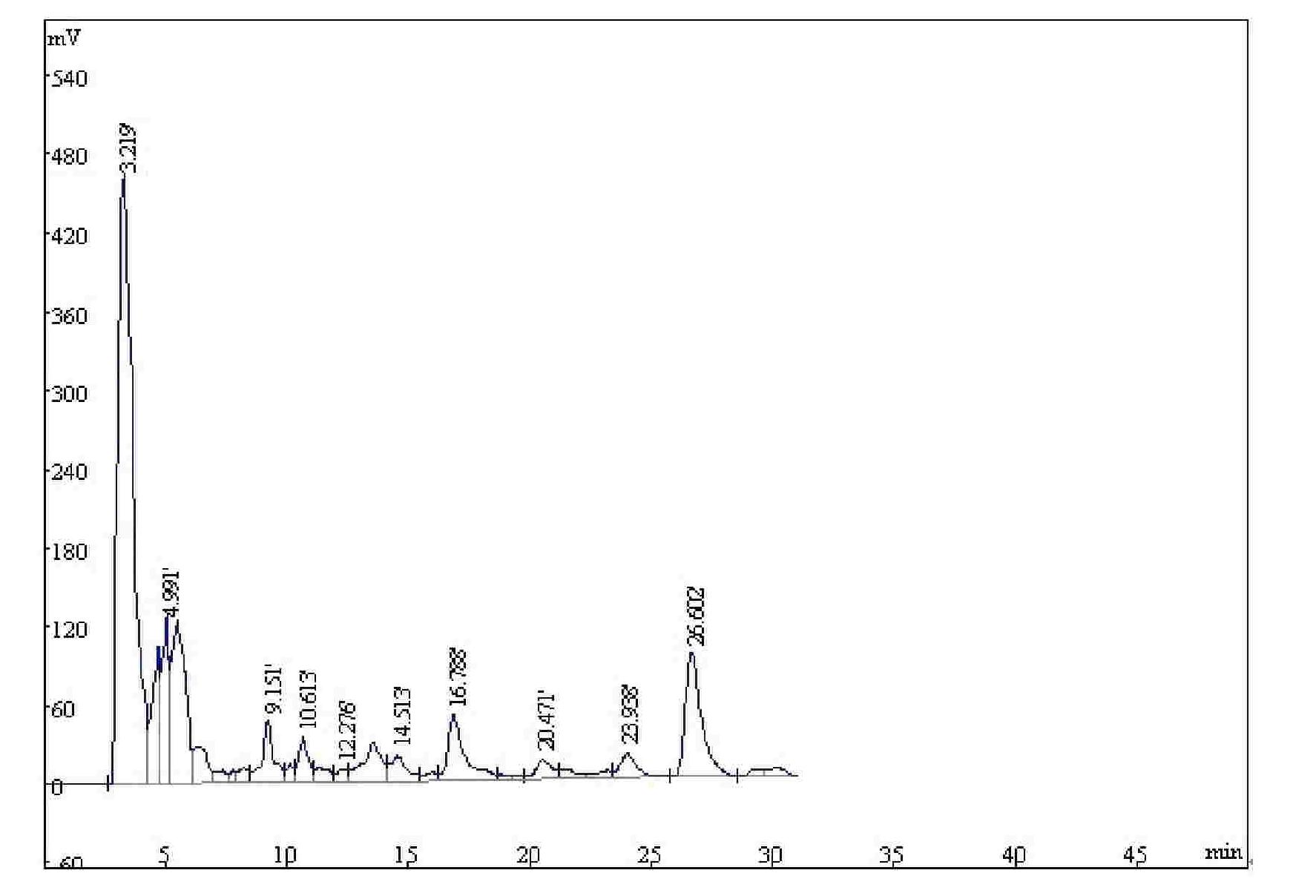

[0048] (1) Extraction of effective parts: take 30KG of Glycyrrhiza glabrata, add 340L of ethanol solution with a volume percentage concentration of 95%, heat and extract three times at 40°C, and the extraction time is 3, 2, and 1 h respectively, and the extracts are combined, Concentrate under reduced pressure at a temperature of 40°C to 50°C, recover ethanol to dryness, and obtain 10 L of the extract, which is detected by HPLC to contain glabridin (see image 3 ).

[0049] (2), enrichment of effective parts and impurity removal: after the extract extract is suspended with 3 times of tap water, an equal volume of chloroform is added for repeated extraction, and the product has been extracted in large quantities by HPLC detection (see Figure 4 ), until the glabridin can not be detected in the aqueous phase, remove the pola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com