Device for enriching and recovering carbon dioxide gas

A carbon dioxide enrichment technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of corrosion, solvent degradation and solvent condensation, limit the application of enrichment and recovery, and reduce the impact of NHD solvents on Carbon dioxide absorption efficiency and other issues, to achieve the effect of solvent stability and applicability enhancement, investment and energy consumption reduction, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Recovery of carbon dioxide in the hydrogen production, the carbon dioxide gas source comes from the split pipeline of the pressure swing adsorption hydrogen production gas source, the pressure is 2.5MPa, the temperature is 40°C, and the gas volume is 21000Nm 3 / h, the gas composition is as follows:

[0018] components

H 2

CO

CO 2

CH 4

h 2 o

total

%(v)

71.23

2.5

21.73

4.32

0.22

100.00

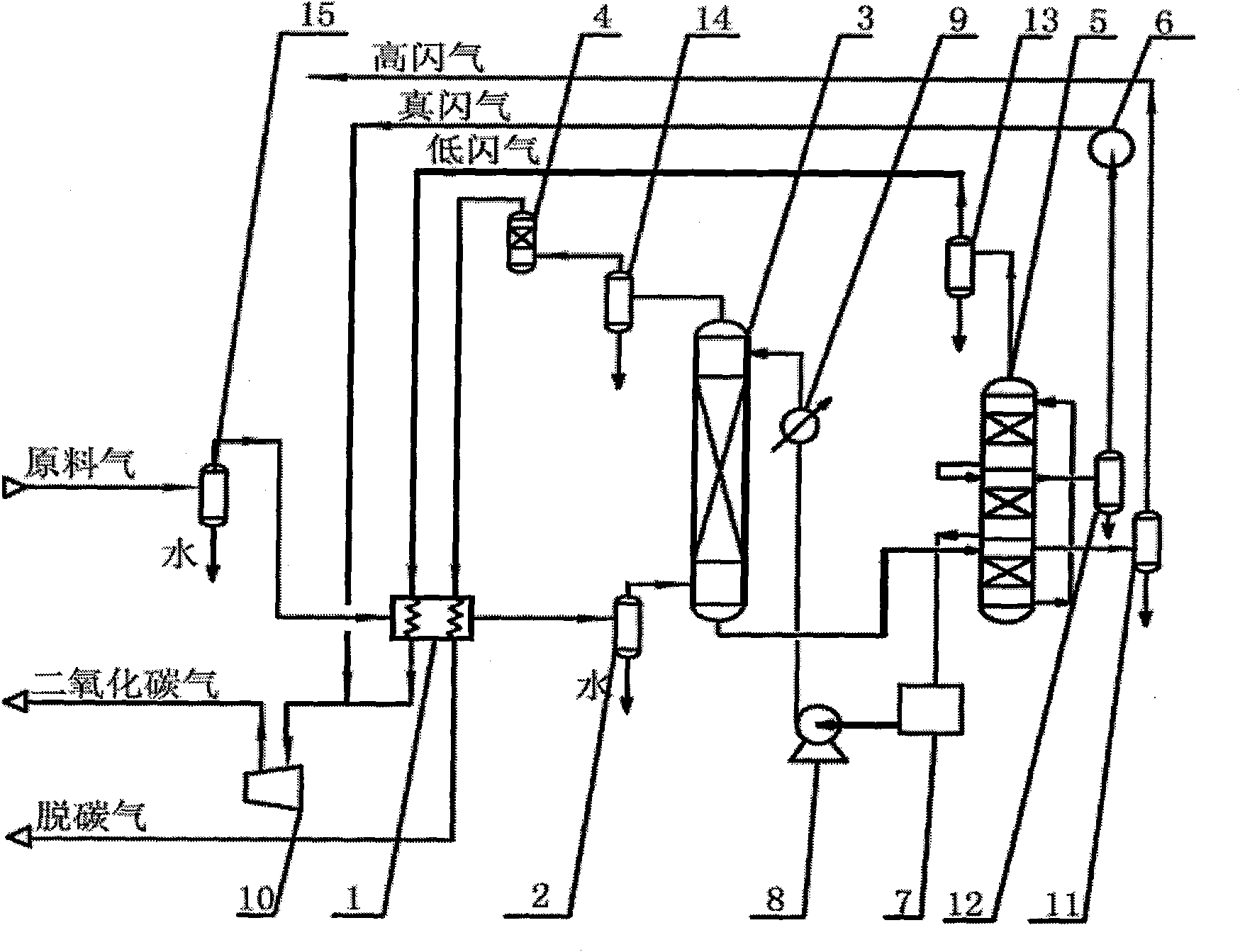

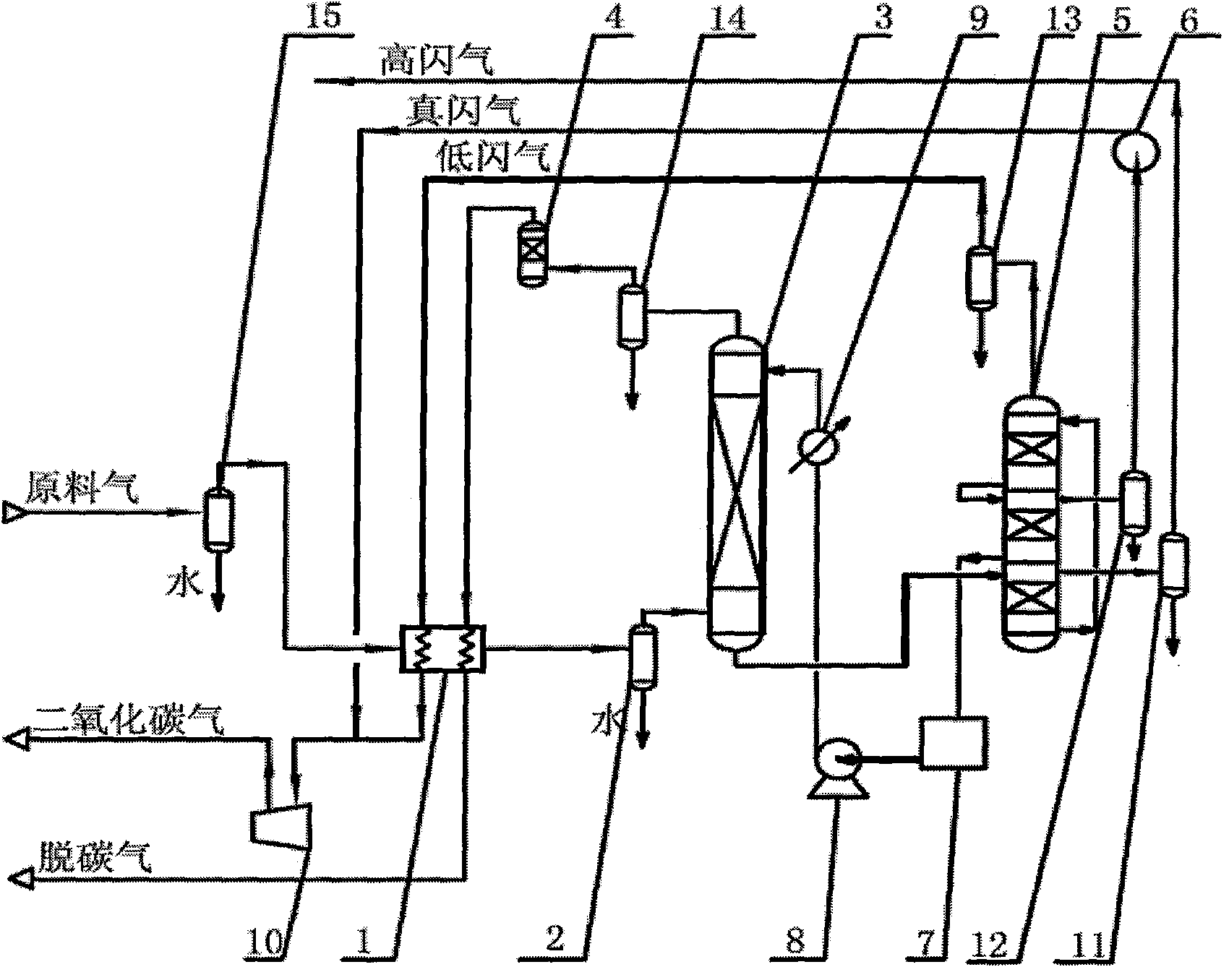

[0019] The raw material gas first passes through the water separator 15 to divide the water, then passes through the heat exchanger 1 to cool down, enters the water separator 2 to remove most of the water, and then enters the absorption tower 3. The decarburized gas enters the liquid separation tank 14 after going out from the top of the tower. The adsorption tank 4 is dehydrated, and then returns to the PSA hydrogen production inlet after passing through the heat exchanger 1; the saturated NHD first ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com