Naphtha and light dydrocarbon transformation method

A technology for naphtha and light hydrocarbons, which is applied in the field of upgrading through two-stage reaction, can solve the problems of elevated catalyst bed temperature and difficult control of reaction heat, and achieves reduction of investment and energy consumption, octane number and production. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

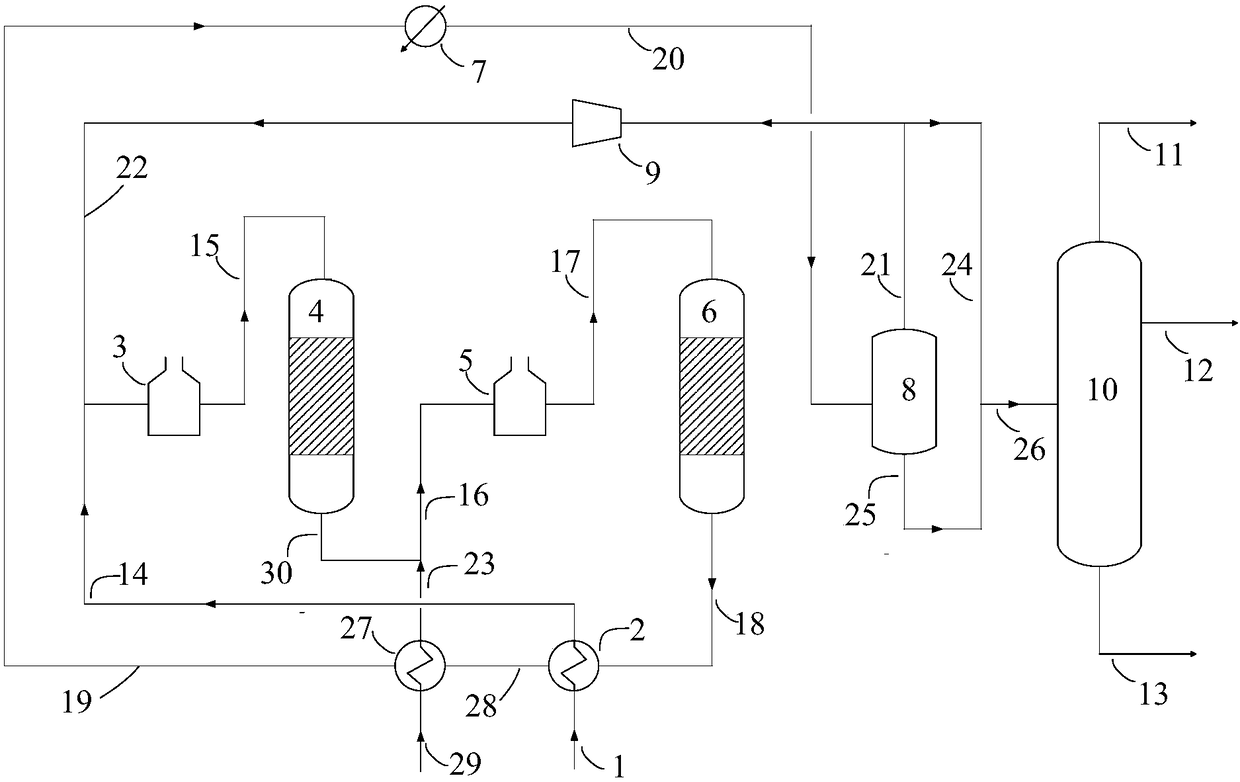

Method used

Image

Examples

example 1

[0058] Preparation of dehydrogenation catalyst.

[0059] Take 100 grams (dry basis 95 grams) of γ-Al 2 o 3The carrier is used as the first carrier, and its saturated water absorption is measured to be 82mL, and a predetermined amount of chloroplatinic acid and hydrochloric acid are used to prepare 140mL of impregnating solution, so that the impregnating solution contains 0.5% by mass of Pt and 1.9% by mass of Cl (both dry with respect to alumina. base mass), the volume ratio of impregnating liquid to carrier is 1.05:1. Separate the carriers into flasks, evacuate and control the vacuum at 0.085MPa, introduce the impregnating solution, rotate and impregnate at 30°C for 3 hours, and rotate at a linear speed of 0.10 m / s, then dry under reduced pressure, and then dry in dry air at 500 ℃, and the gas / solid volume ratio is 700:1 and baked for 4 hours. The catalyst prepared by the above method contains 0.5% by mass of Pt and 1.0% by mass of Cl based on the dry weight of the alumina...

example 2

[0061] Preparation of modified catalysts.

[0062] (1) Preparation of the second carrier

[0063] Get 120 grams of HZSM-5 molecular sieve powder (produced by Shanghai Huaheng Chemical Plant) with a silica / alumina molar ratio of 56, and 80 grams of aluminum hydroxide powder (produced by Qilu Catalyst Plant, with an alumina content of 76% by mass), and stir evenly Finally, add 4 milliliters of nitric acid with a concentration of 40% by mass and 100 milliliters of deionized water, knead fully, extrude into strips with a diameter of 2 mm, dry at 110 ° C for 8 hours, cut into particles with a length of 2-3 mm, and then dry them at 570 ° C Roast for 4 hours.

[0064] (2) Preparation of catalyst

[0065] Take 100 grams of the above-mentioned second carrier, use 100 milliliters containing 1.0 grams of mixed rare earth chloride (produced by Inner Mongolia Baotou Rare Earth Industry Company, which contains 31 mass % of lanthanum oxide, 51 mass % of cerium oxide, 14 mass % of An aqueo...

example 3

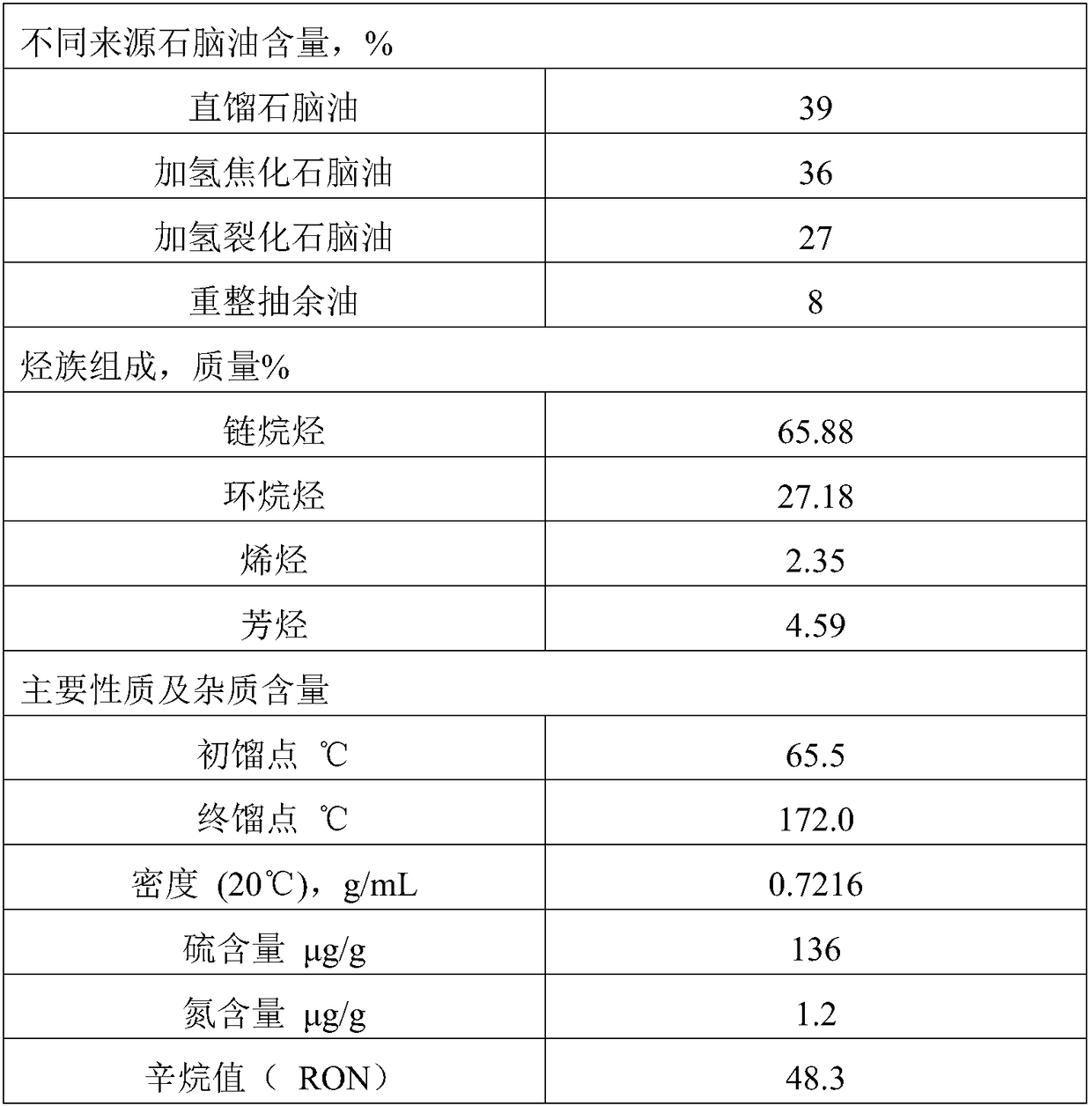

[0068] According to the method of the invention, naphtha and light hydrocarbons are upgraded.

[0069] In the laboratory fixed-bed four-reactor adiabatic medium-scale test device (four reactors in the device are arranged in series, each reactor is equipped with an independent raw material oil and raw gas feeding system, and the outlets of the first three reactors are equipped with online chromatography. instrument, which can detect the composition of the reactor outlet product in real time, and the device is equipped with a gas cycle compressor), and the first two reactors are filled with catalysts, and the total loading amount of the catalyst is 120g, wherein the first reactor is filled with the dehydrogenation catalyst prepared by 15g example 1 , the second reactor was loaded with the modified catalyst prepared in Example 2 of 105g.

[0070] The dehydrogenation catalyst and the modified catalyst are activated before the reaction in the device. The activation medium is nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com