Manufacturing method of radiator with high heat transfer efficiency

A heat sink, high-efficiency technology, applied in the technical field through anodic treatment, can solve the problems of unsatisfactory heat dissipation performance, high cost, temperature rise effect of computer or electronic components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

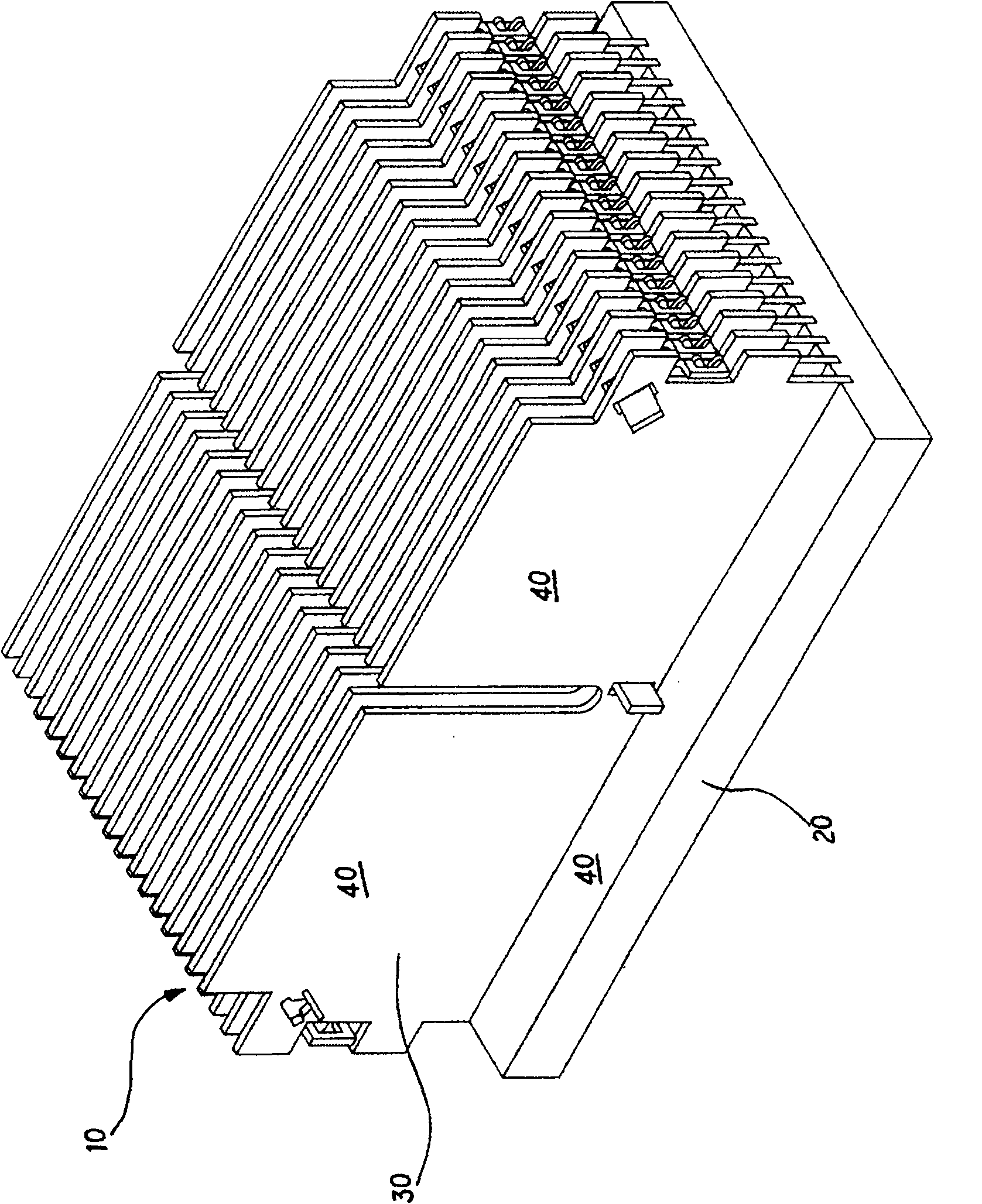

[0023] The present invention is a method for making a heat sink with high heat transfer efficiency, please refer to figure 1 As shown, the composition of the heat sink 10 includes a base 20. The base 20 can be a rectangle, a circle, a geometric shape or an irregular shape and a side surface is attached to a heat source (not shown), and the heat source includes but is not limited to an integrated circuit. , a chip or a light-emitting diode module, the other side of the base 20 is combined with a plurality of fins 30, which can be combined by welding, riveting, stamping or gluing with a heat pipe, so that the fins 30 and the base 20 are tightly integrated into one, and the heat source is generated. The heat of the radiator is conducted to the fins 30 through the base 20 for heat dissipation;

[0024] According to the Stefan-Boltzman Law (Stefan-Boltzman Law), it is stated that at absolute temperature T, the rate of total radiation emitted from a black body is Qb=AσT 4 , where A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com