Method for preparing propylene glycol monomethyl ether acetate (PMA) by continuous reaction and distillation

A production method and reactive distillation technology, which are applied in the field of continuous reactive distillation to prepare propylene glycol methyl ether acetate, can solve the problems of long reaction time, high material consumption and energy consumption, complicated operation and the like, and achieve the reduction of equipment corrosion rate and acetic acid mono Consumption, the effect of convenient process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

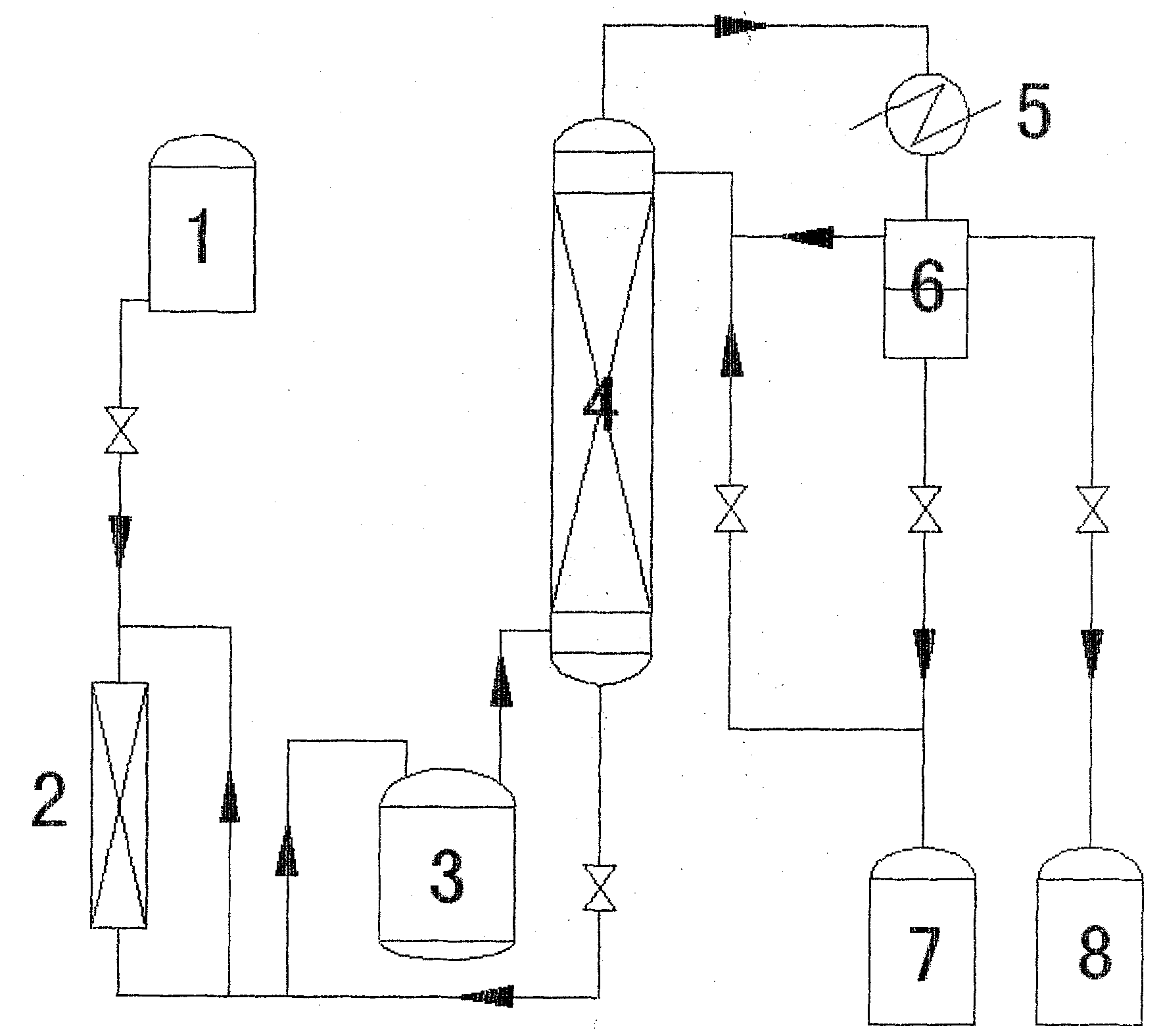

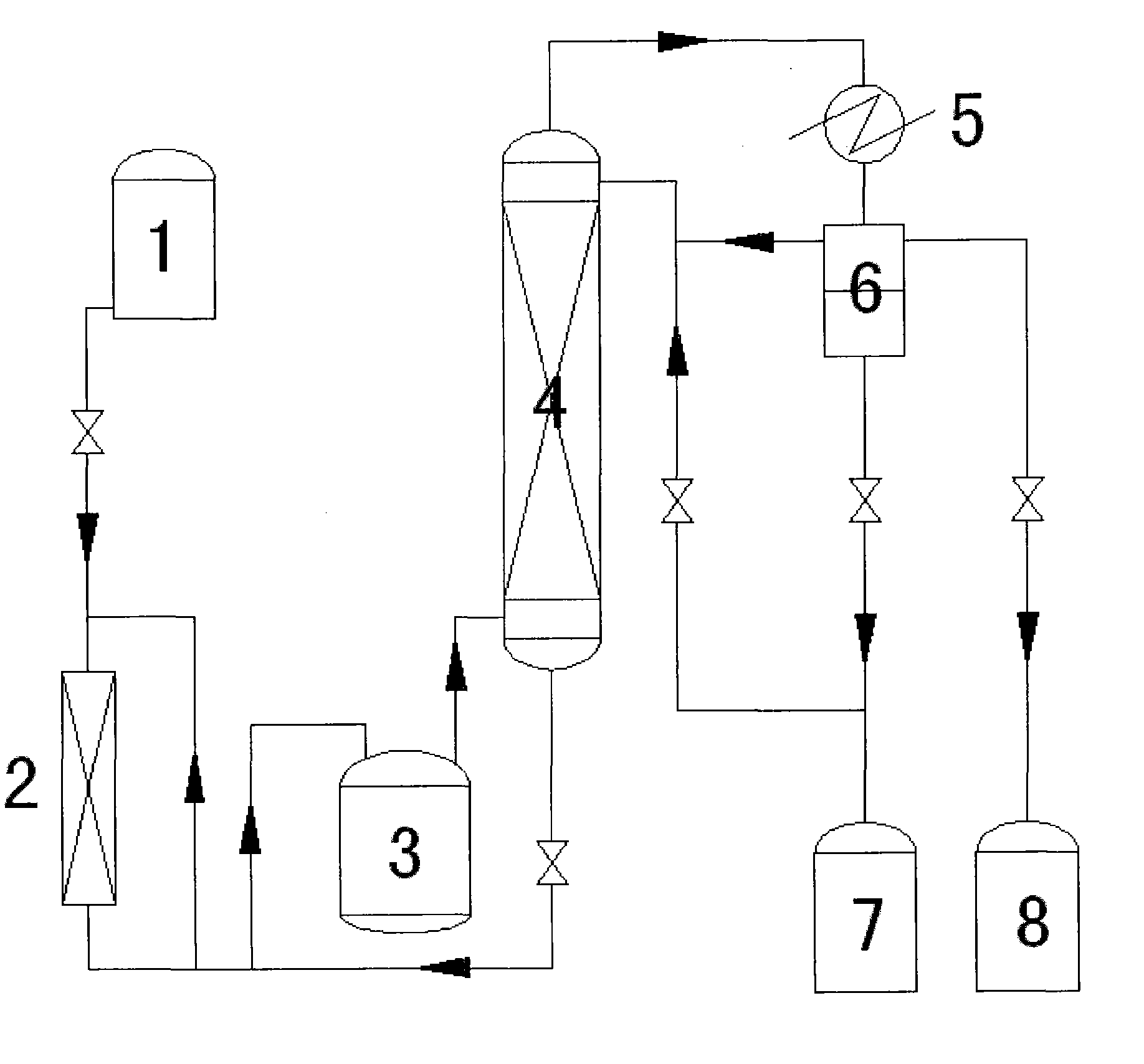

[0025] Raw materials PM and acetic acid are prepared in a molar ratio of 1:1 and fully mixed in the 1-raw material tank. The raw materials enter the 2-fixed-bed reactor for preliminary esterification reaction, and the fixed-bed reaction is heated by external circulation. The fixed bed reaction temperature is controlled at 70-80°C. The catalyst used is a sulfonic strong acid cation exchange resin X with macromolecular structure. The circulation ratio used by the fixed bed is R=3-5. The pre-reaction discharge material enters the esterification kettle, and the reaction temperature of the kettle is controlled at 110-140°C. The design of the esterification tank allows the reaction materials to be fully mixed while prolonging the residence time. The catalyst used in the esterification tank is methanesulfonic acid, and the catalyst consumption is 1.5w% of the tank liquid. The crude reaction product enters the bottom of the esterification tower after being heated and vaporized. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com