Method for gasifying and incinerating combustible solid wastes by utilizing rotary kiln

A solid waste, rotary kiln technology, applied in the field of resources and environment, can solve the problems of high operation and management costs, harm to health, long processing cycle, etc., to achieve the effect of improving resource utilization, avoiding secondary pollution, and improving environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

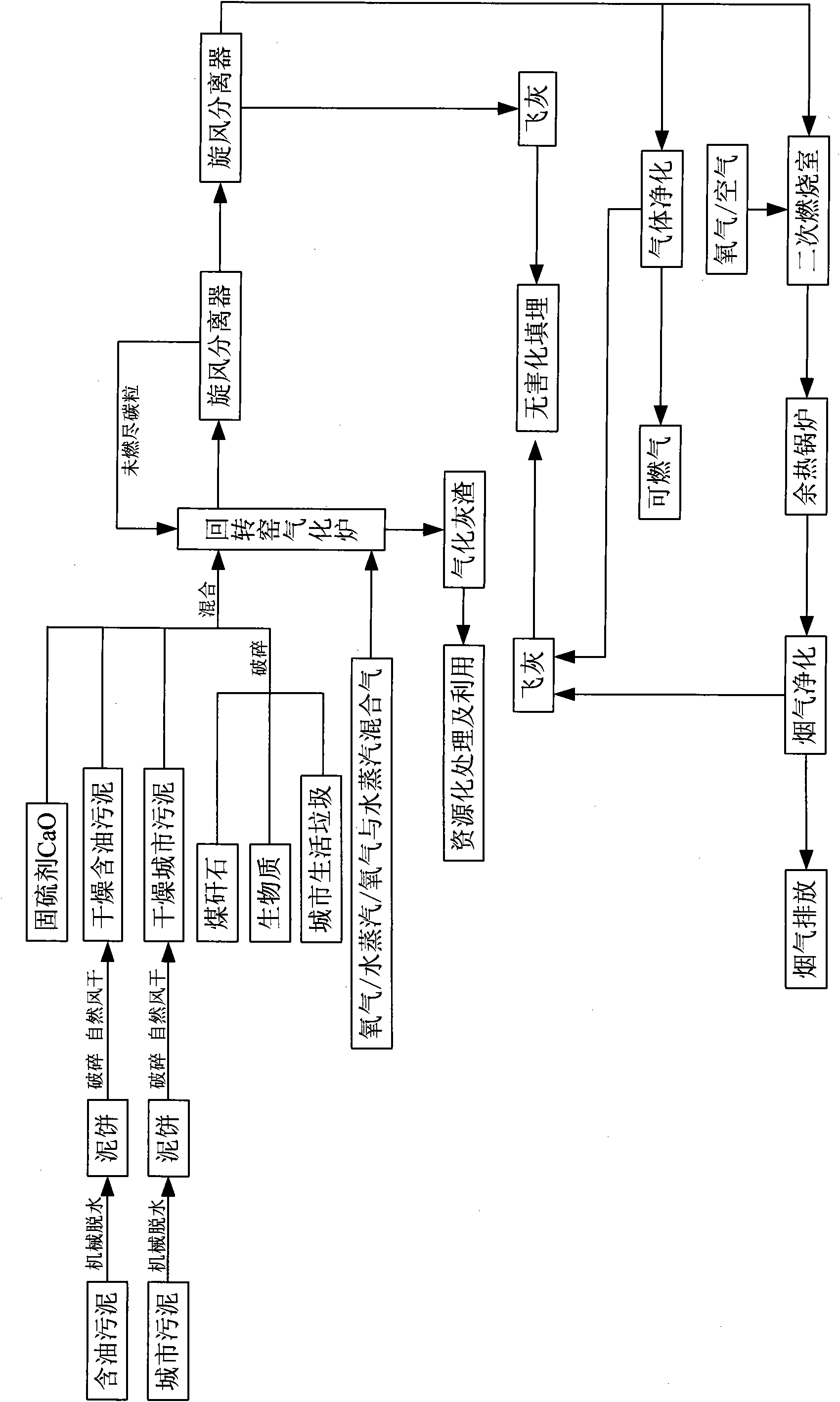

Image

Examples

Embodiment 1

[0030] Example 1: The oily sludge and urban sludge are fully stirred respectively and then mechanically dehydrated to obtain a mud cake with a moisture content of 40-50%. The obtained mud cake is broken and air-dried for more than 100 hours under natural conditions. When it contains water When the rate is 10-20%, store it for later use. Mix dry oily sludge, dry municipal sludge, crushed coal gangue, municipal solid waste, biomass and limestone at a ratio of 25%, 25%, 10%, 20%, 15% and 5% respectively and pass through the spiral The feeder feeds into the counter-flow rotary kiln gasifier. At 1100°C, the combustible components in the combustible solid waste mixture react with oxygen to generate partial combustion reaction to form H 2 , CO, CO 2 and a small amount of C n h m The crude gas, where H 2 And CO volume fraction reaches about 77%. The crude gas enters the secondary combustion chamber for full combustion after passing through the two-stage cyclone separator, and th...

Embodiment 2

[0031] Example 2: The drying process of oily sludge and urban sludge is as in Example 1. Mix dry oily sludge, dry municipal sludge, crushed coal gangue, municipal solid waste, biomass and limestone at a ratio of 20%, 20%, 20%, 25%, 10% and 5% respectively and pass through the spiral The feeder feeds into the rotary kiln gasifier. At 1150°C, the combustible components in the combustible solid waste mixture react with oxygen to partially burn to form H 2 , CO, CO 2 and a small amount of C n h m The crude gas, where H 2 And CO volume fraction reaches about 74%. The crude gas enters the secondary combustion chamber for full combustion after passing through the two-stage cyclone separator, and the high-temperature flue gas generated is recovered by the waste heat boiler and further purified for harmless discharge. Organic pollutants in oily sludge, municipal sludge, and municipal solid waste are decomposed at high temperature, and pathogenic bacteria and parasites are also ki...

Embodiment 3

[0032] Example 3: The drying process of oily sludge and urban sludge is as in Example 1. Mix dry oily sludge, dry municipal sludge, crushed coal gangue, municipal solid waste, biomass and limestone at a ratio of 15%, 15%, 10%, 20%, 37% and 3% respectively and pass through a spiral The feeder feeds into the rotary kiln gasifier. At 1200°C, the combustible components in the combustible solid waste mixture react with oxygen to partially burn to form H 2 , CO, CO 2 and a small amount of C n h m The crude gas, where H 2 And CO volume fraction reaches about 80%. The crude gas with more fly ash separated by the secondary cyclone separator is used to produce H-rich gas after further gas purification. 2 and CO clean combustible gas, where H 2 and CO volume fractions were 29% and 53%, respectively. Organic pollutants in oily sludge, municipal sludge, and municipal solid waste are decomposed at high temperature, and pathogenic bacteria and parasites are also killed at high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com