Manufacturing method of thin film transistor and transistor manufactured by method

A technology of thin film transistors and manufacturing methods, applied in the direction of transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of complex process, complex production process of thin film transistors, high production cost, etc., and achieve small electrode area, large numerical aperture, The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

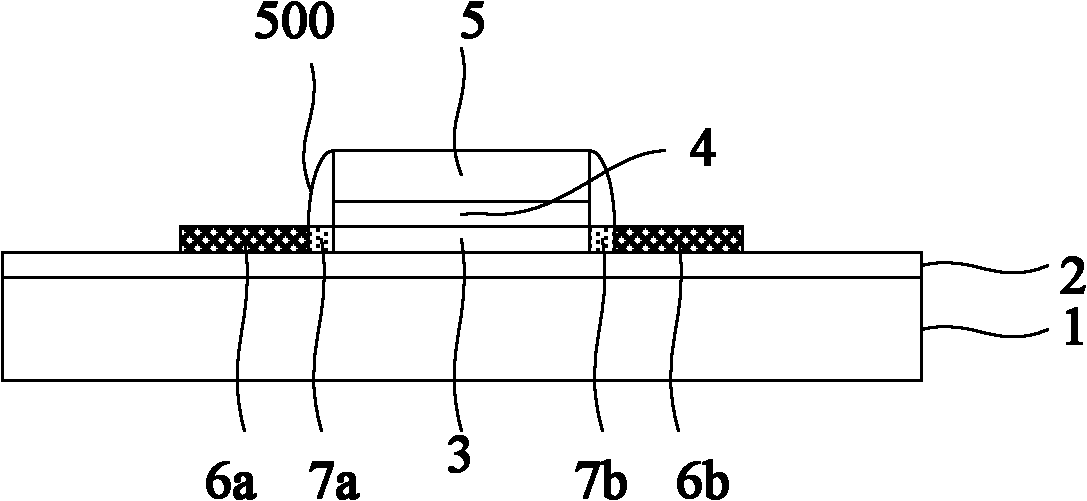

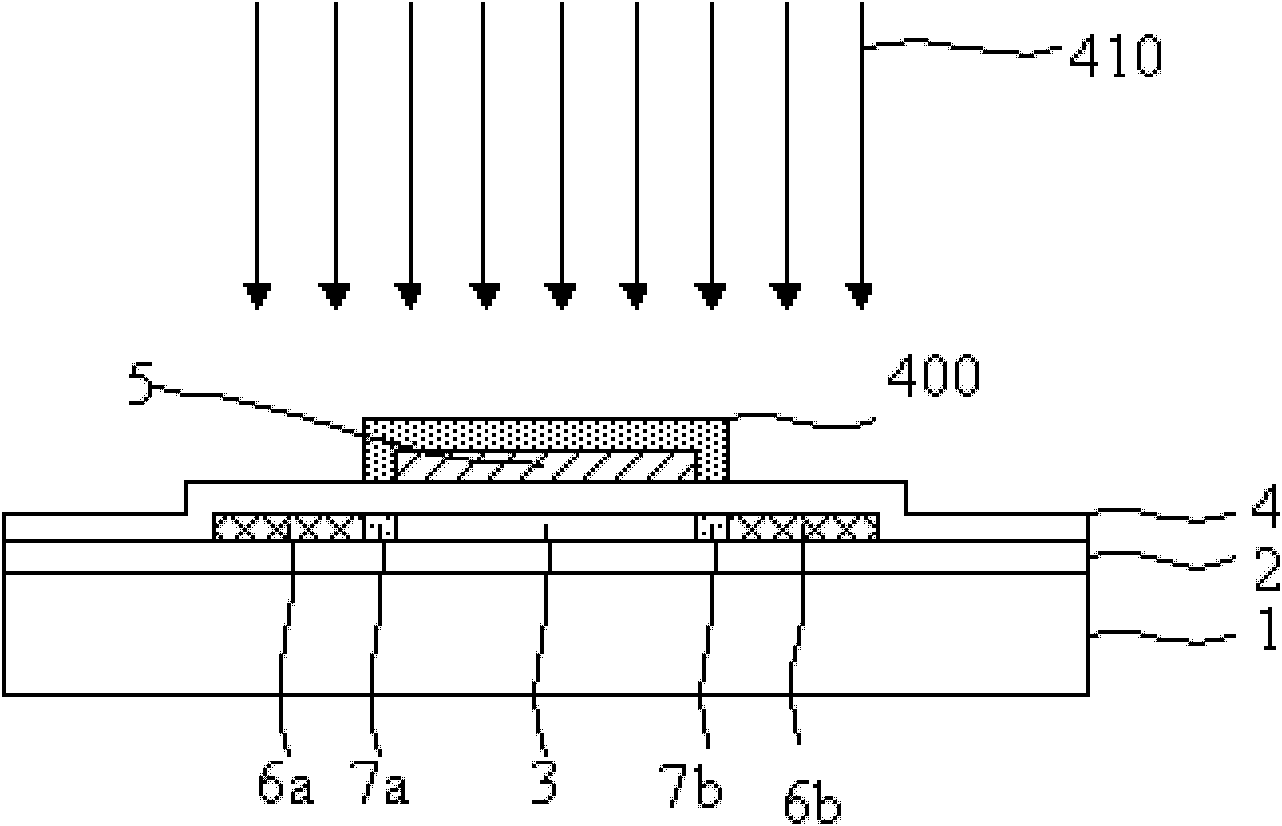

[0028] refer to Figure 4A to Figure 4D , the manufacturing method of the thin film transistor of this embodiment includes the following steps:

[0029] (1) Reference Figure 4A , continuously deposit the surface covering layer 2 and the intrinsic a-Si layer (the intrinsic a-Si layer is the original state of the polysilicon island active layer 300 by PECVD method on the glass substrate, quartz or other substrate 1, only shown in the figure The polysilicon island active layer 300 is shown, and the intrinsic a-Si layer is not shown), wherein the surface capping layer 2 can prevent the diffusion and penetration of substrate impurities such as metal ions into the silicon active layer, which can be made of a single layer of silicon nitride ( SiNx), silicon oxide (SiO 2 ) is made or has a double-layer structure, the optimized surface covering layer 2 adopts thick silica. The thickness of the a-Si layer is optimized for

[0030] (2) Dehydrogenation of a-Si layer

[0031] (...

Embodiment 2

[0040] The auxiliary layer 910 is formed on the gate conductive layer 510 according to the method of the first embodiment, wherein the auxiliary layer 910 and the gate insulating layer 4 use the same film material and the same manufacturing process. The thickness of the auxiliary layer 910 determines the dopant dose of the lightly doped region, and its thickness is between between. A better example uses silicon nitride as the gate insulating layer. At this time, the auxiliary layer is also silicon nitride. The way to form silicon nitride is to use PECVD process, the reaction gas is SiH4 / NH3, and the optimized auxiliary layer thickness is

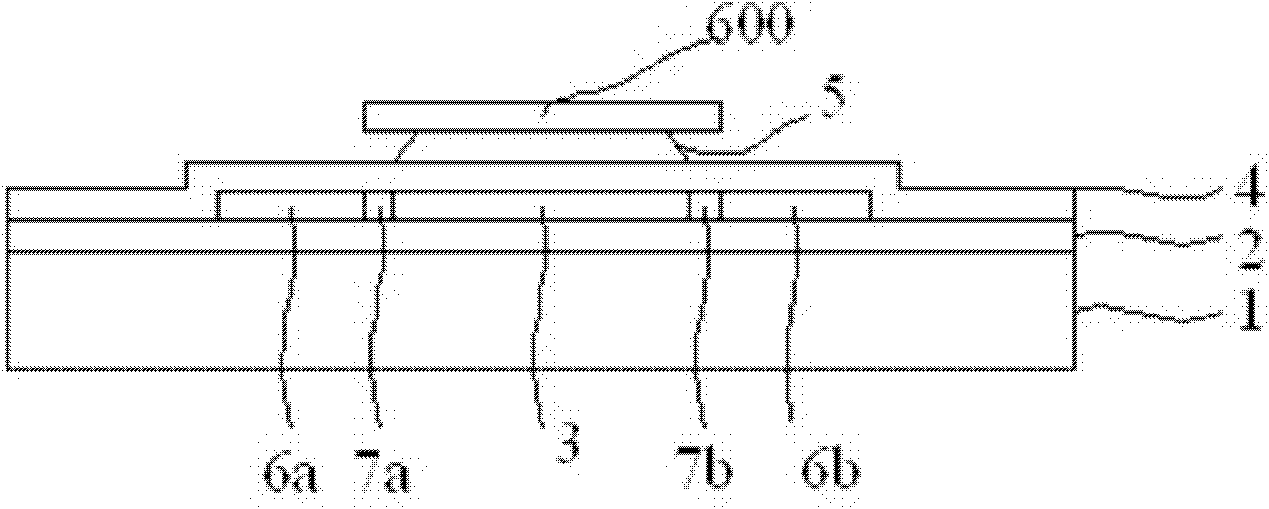

[0041] After the LDD formation layer 9 is formed according to the method of Embodiment 1, the photoresist is not removed, and the gate conductive layer 510 is over-etched by a wet method to form the gate 5. The width of the gate is smaller than the width of the photoresist pattern, and the optimized photoresist The width of the pattern i...

Embodiment 3

[0044] A manufacturing method of a thin film transistor according to another embodiment includes the following steps.

[0045] The auxiliary layer 910 is formed on the gate conductive layer 510 according to the method of the first embodiment, wherein the auxiliary layer 910 and the gate insulating layer 4 adopt the same film material and the same manufacturing process. The thickness of the auxiliary layer 910 determines the dopant dose of the lightly doped region, and its thickness is between between. A better example uses silicon nitride as the gate insulating layer. At this time, the auxiliary layer is also silicon nitride. The method of forming silicon nitride is PECVD process, and the reaction gas is SiH4 / NH3. The optimized auxiliary layer thickness and gate insulating layer The same thickness, both

[0046] After the LDD formation layer 9 is formed according to the method of Embodiment 1, the photoresist is not removed, and the gate conductive layer 510 is over-etche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com