Novel composite ecological cement and product application thereof

An ecological cement and composite cement technology, applied in applications, ceramic products, other household appliances, etc., can solve the problems of serious shrinkage cracking, too fast setting time, restricting promotion, etc. large amount of effect

Inactive Publication Date: 2010-09-29

汪超

View PDF0 Cites 94 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Using high-concentration strong alkali and alkali metal silicates and carbonates as activators to activate slag powder to make alkali-activated slag cement was first invented by Ukrainian scientist Glukhovsky in 1957. It has many silicates Cement does not have excellent properties, such as early strength and high strength, low water demand, low heat of hydration, and a large amount of waste residue, etc., but this composite cement also has many shortcomings, such as back to alkali pulverization, fast setting time, and high cost. The most important thing is that its shrinkage cracking is very serious, and its serious cracking problem greatly restricts the promotion of this cement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

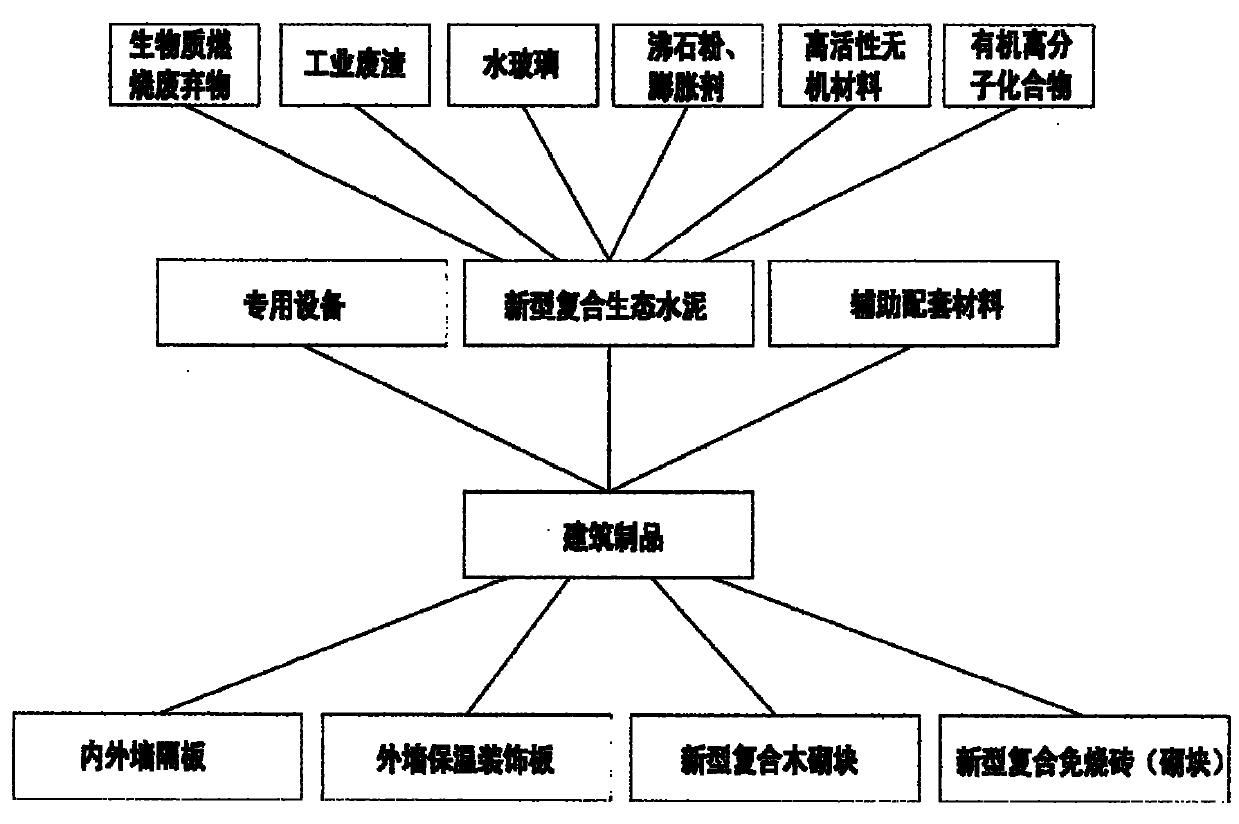

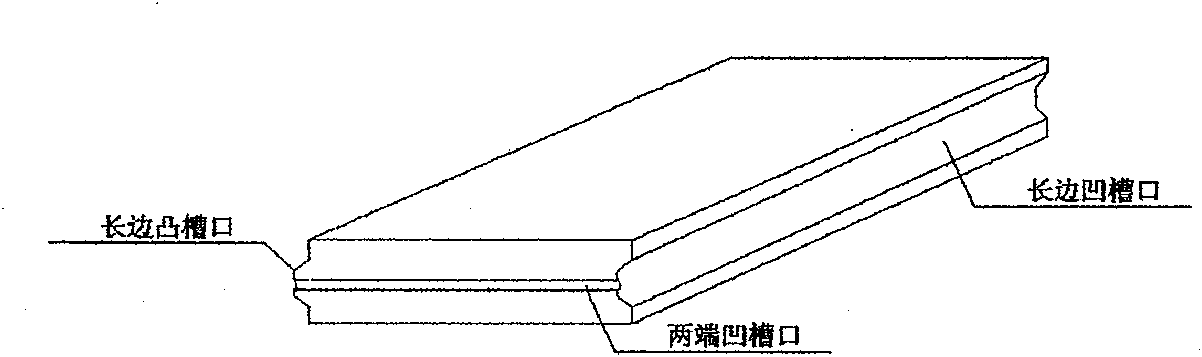

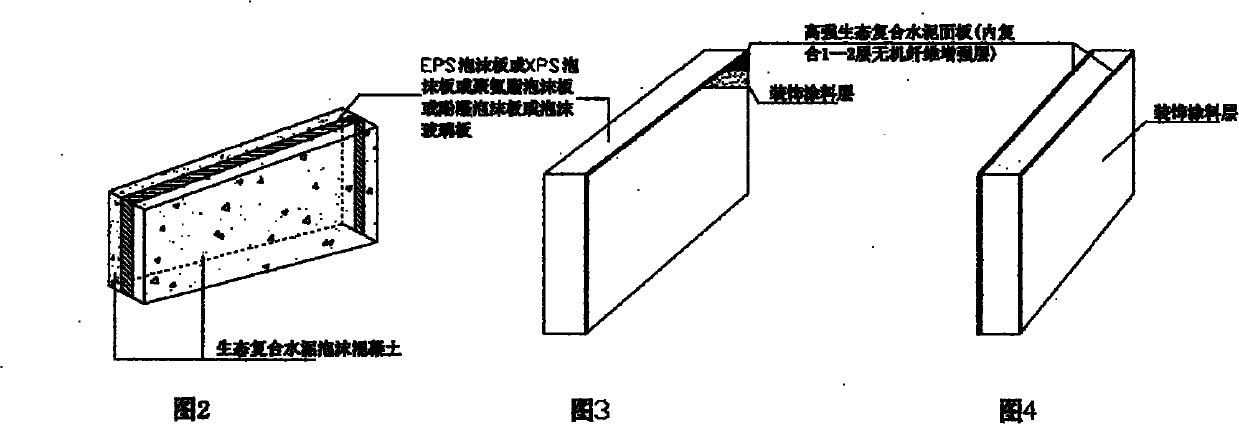

The invention discloses composite ecological cement produced by using reproducible biomass combustion wastes, industrial residues and the like as main raw materials (the utilization ratio of the biomass combustion wastes and the industrial residues is over 80 percent). The novel gelling material namely the composite ecological cement is combined with other environment-friendly materials such as a paper honeycomb panel and the like to compound and manufacture a novel environment-friendly building product, such as a novel super-lightweight high-strength inner wall composite partition plate (having a dead weight of about 19 kilograms per square meter) special for novel high-rise and multi-layer frame constructions, a 65 percent self-heat preservation lightweight high-strength outer wall partition plate, an outer wall heat preservation and decoration integrative plate, a novel composite wood building block, a novel composite baking-free brick, novel bubble concrete and the like; and all the products are detected by a national level building material detection institution, reach a related product quality standard, are manufactured in factory by using specified machinery, are mounted and manufactured on site and are efficient and economical. The composite ecological cement uses various reproducible resources and various reclaimable wastes to the utmost extent, protects the environment, saves energy, reduces discharge and the overall comprehensive engineering manufacturing cost, and has important economic and social benefits.

Description

Technical field: The present invention uses renewable biomass burning waste and industrial waste residue as main raw materials (the utilization rate of biomass burning waste and industrial waste residue reaches more than 80%) to produce ecological composite cement, and then uses this new type of cementitious material to combine with other environmental protection materials Composite manufacturing of new environmentally friendly building products such as paper honeycomb panels, such as ultra-light and high-strength interior wall composite partition panels for new high-rise and multi-storey frame buildings (about 19 kg per square meter), 65% self-insulation and light weight High-strength exterior wall partitions, exterior wall insulation and decoration integrated boards, new composite wood blocks, new composite non-fired bricks, new foam concrete, etc., all products have passed the inspection of national building materials testing institutions and reached relevant product quality ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B7/28C04B28/04C04B38/00

CPCC04B2111/00318C04B2111/28C04B2111/00017C04B2103/0007C04B2111/40C04B2111/60C04B28/26Y02W30/91C04B12/04C04B14/047C04B14/106C04B18/068C04B18/08C04B18/101C04B18/12C04B18/141C04B18/146C04B20/0092C04B22/0086C04B22/062C04B24/2623C04B24/307C04B24/383C04B40/0071C04B2103/0053C04B2103/0057C04B24/26C04B40/0082C04B14/00C04B18/04C04B18/06C04B22/008C04B24/24

Inventor 汪超

Owner 汪超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com