Pelleting method of titanium diboride powder

A powder and granulation technology, applied in the field of aluminum electrolysis, can solve the problems of poor wettability, affecting the wettability of the surface of the cathode material and the aluminum liquid, and unable to achieve a wettable diversion cathode, achieving low cost, anti-electrolyte and other problems And the effect of strong sodium permeability and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

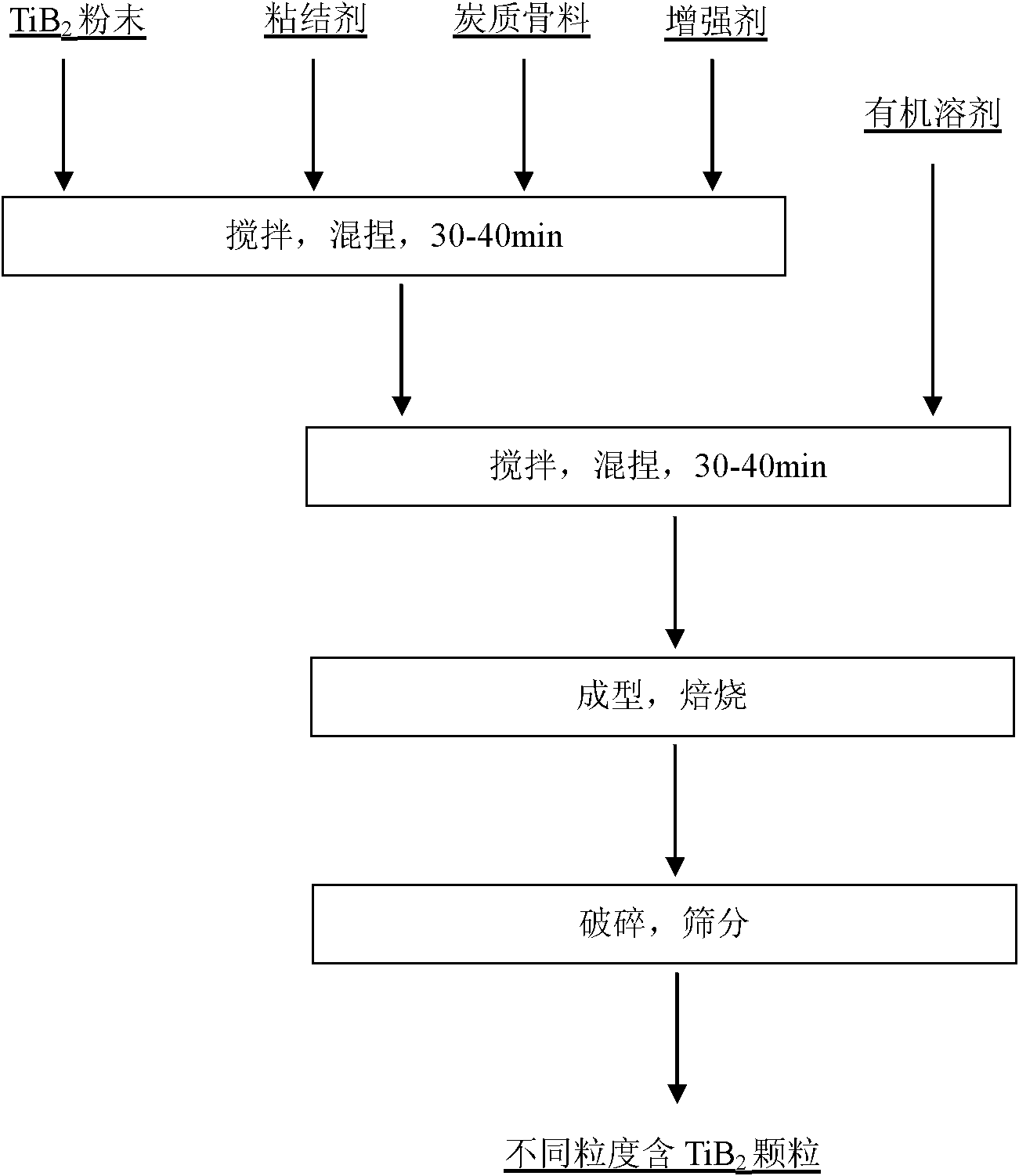

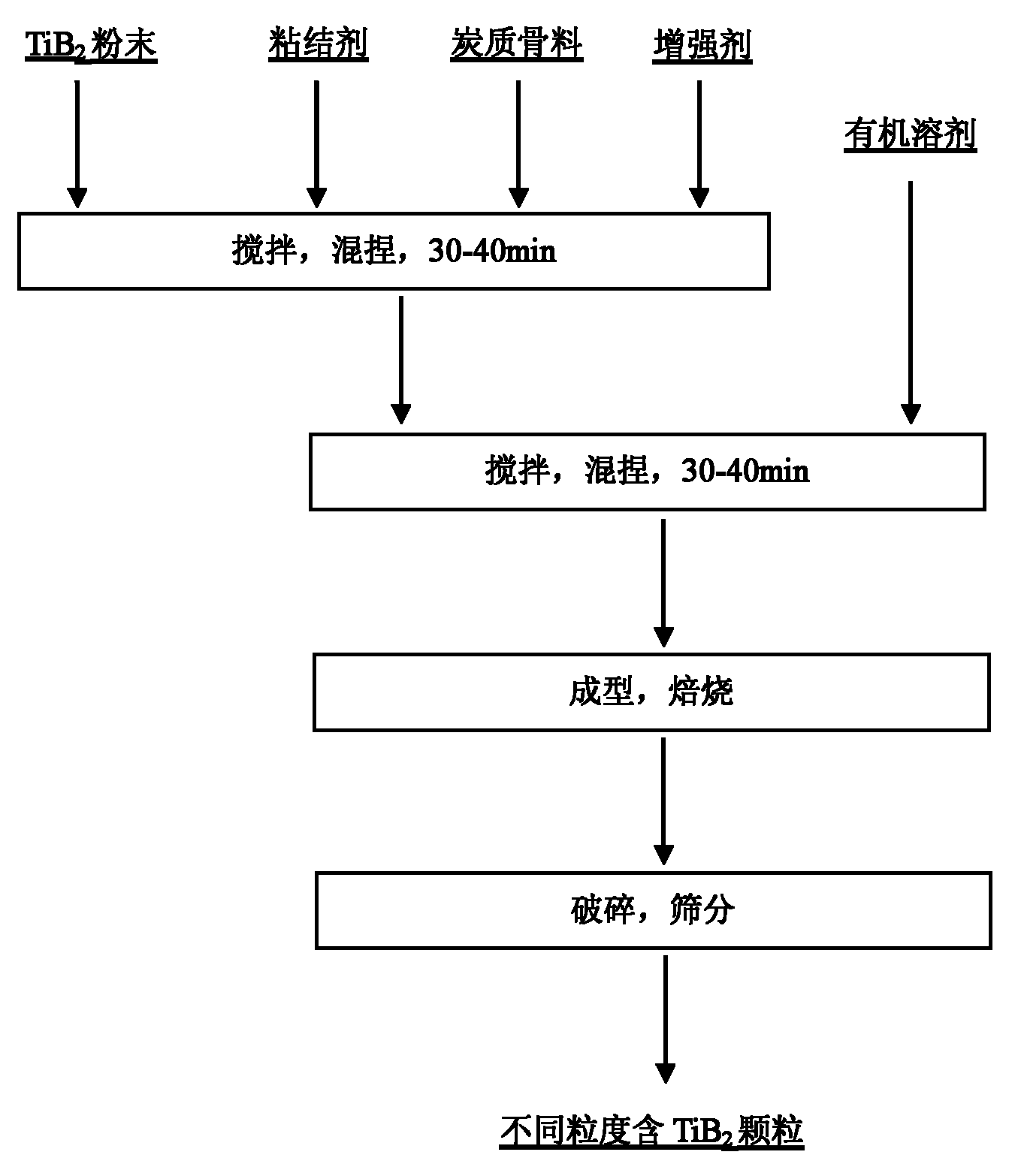

Method used

Image

Examples

Embodiment 1

[0030] Granulation formula: aggregate 80% (of which TiB 2 powder: 85%, petroleum coke: 15%); coal tar pitch: 20%.

[0031] Weigh according to the above dosage, knead in a kneader, and after mixing, shape under 180MPa molding pressure. Bury the molded product with coke and roast it. At the beginning, the temperature is raised slowly (8-15°C / h) to 600°C, and then the temperature is relatively fast (15-25°C / h) to 900°C, and the temperature is kept for 6-15h. Rapid cooling (30-40°C / h) to 600°C, and then furnace cooling to room temperature. Use the jaw crusher to crush the roasted product and screen to obtain high-content TiB with different particle sizes 2 Particles (the choice of sieve depends on the required TiB 2 The particle size depends on the size of the particles. Generally, the sieve with the required particle size and the number of meshes at the same distance (as shown in Table 1) is generally selected. For example: TiB with a particle size of about 1000 μm is now req...

Embodiment 2

[0033] Granulation formula: aggregate 80% (of which TiB 2Powder: 100%, petroleum coke: 0%); coal tar pitch: 20%.

[0034] Weigh according to the above dosage, heat the asphalt to the molten state, then knead it with the aggregate, after mixing, shape it under 180MPa molding pressure. Bury the molded product with coke and roast it. At the beginning, the temperature is raised slowly (8-15°C / h) to 600°C, and then the temperature is relatively fast (15-25°C / h) to 900°C, and the temperature is kept for 6-15h. Rapid cooling (30-40°C / h) to 600°C, and then furnace cooling to room temperature. Use the jaw crusher to crush the roasted product and screen to obtain high-content TiB with different particle sizes 2 particles. The TiB 2 Particle bulk density is 2.23g / cm 3 , The porosity is 17.0%, the compressive strength is 35MPa, the resistivity is 25μΩ·m, it is completely wetted with molten aluminum, no cracks, good thermal shock resistance and long service life.

Embodiment 3

[0036] Granulation formula: aggregate 80% (of which TiB 2 powder: 85%, petroleum coke: 15%); coal tar pitch + epoxy resin: 20%.

[0037] Weigh the material according to the above dosage, dissolve the epoxy resin with acetone, then mix it with asphalt and aggregate, and mold it under 180MPa molding pressure after mixing. Bury the molded product with coke and roast it. At the beginning, the temperature is raised slowly (8-15°C / h) to 600°C, and then the temperature is relatively fast (15-25°C / h) to 900°C, and the temperature is kept for 6-15h. Rapid cooling (30-40°C / h) to 600°C, and then furnace cooling to room temperature. Use the jaw crusher to crush the roasted product and screen to obtain high-content TiB with different particle sizes 2 particles. The TiB 2 Particle bulk density is 2.18g / cm 3 , the porosity is 20.1%, the compressive strength is 30MPa, the resistivity is 28μΩ·m, it is completely wetted with molten aluminum, no cracks, good thermal shock resistance and lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com