Process for milling nickel-based alloy by nanoparticles at high speed and nano cutting fluid

A nickel-based alloy, nano-cutting technology, applied in a method of mechanical processing and the field of cutting fluid, can solve problems such as difficult to take away heat, poor fluidity of solid materials, difficult cutting process, etc., to improve processing quality and economic benefits , tool loss reduction, high application value and market prospects

Active Publication Date: 2010-10-06

HIGH END EQUIP & RAIL TRANSIT TECH R & D CENT OF HAIAN TAIYUAN UNIV OF SCI

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the poor fluidity of solid matter, it is difficult to participate in the cutting process and it is difficult to take away heat, so it has not been paid attention to.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

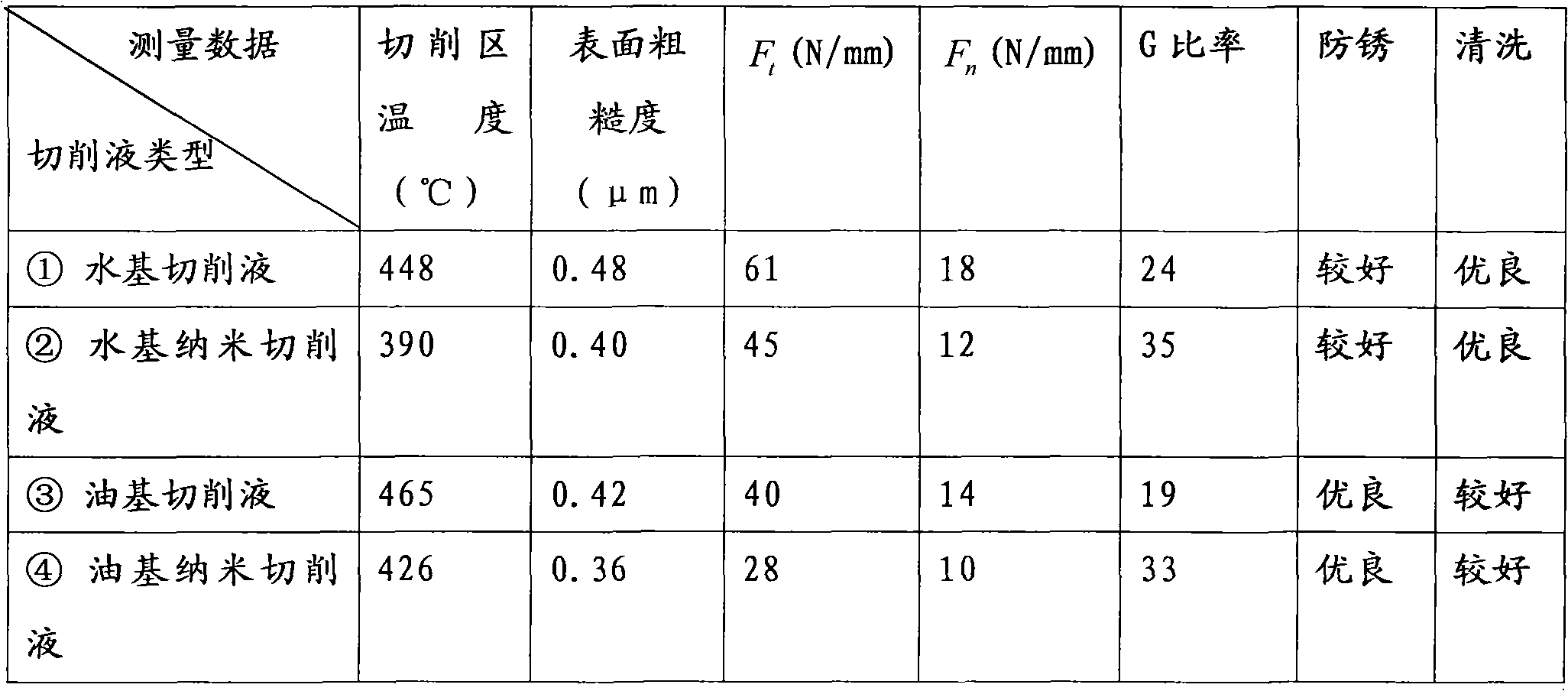

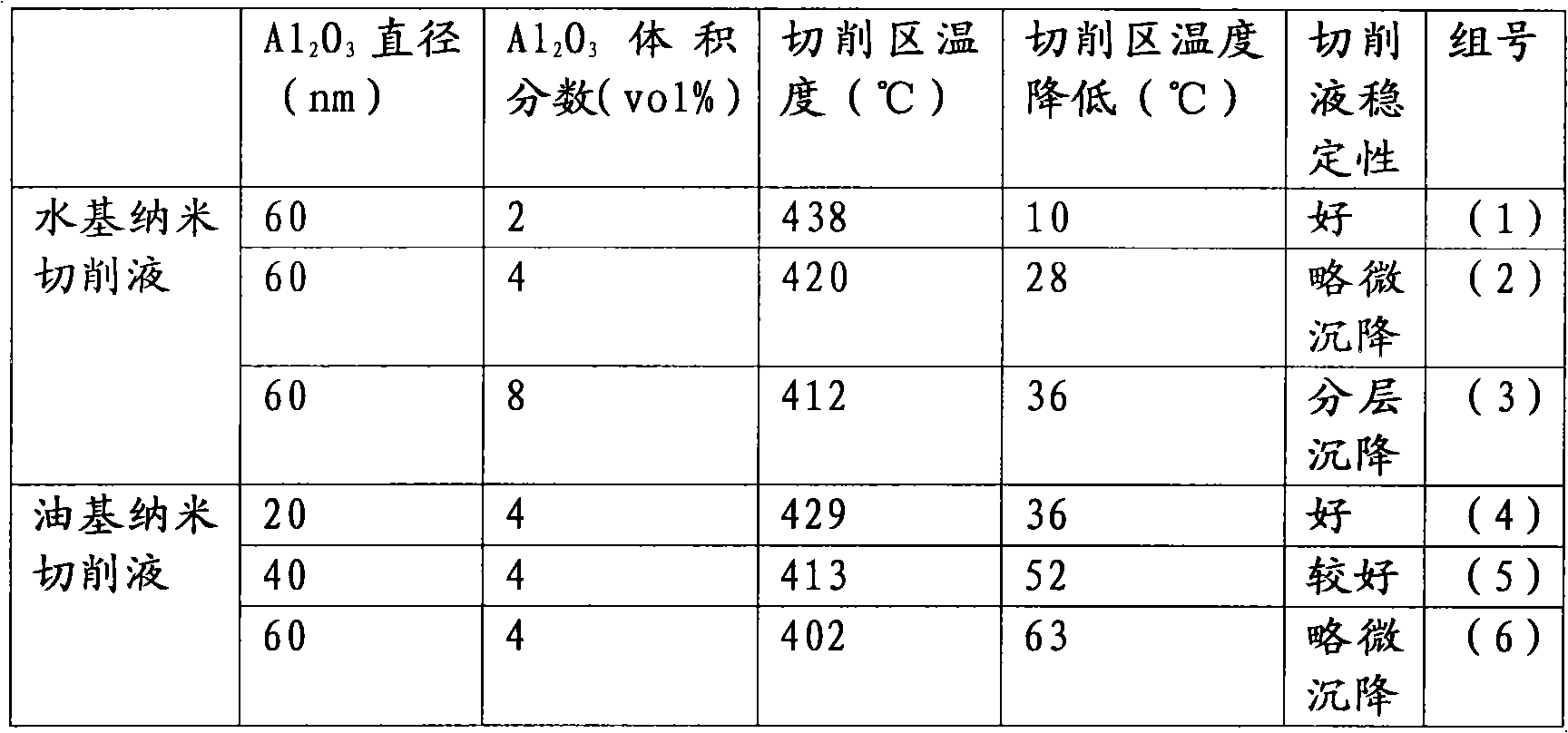

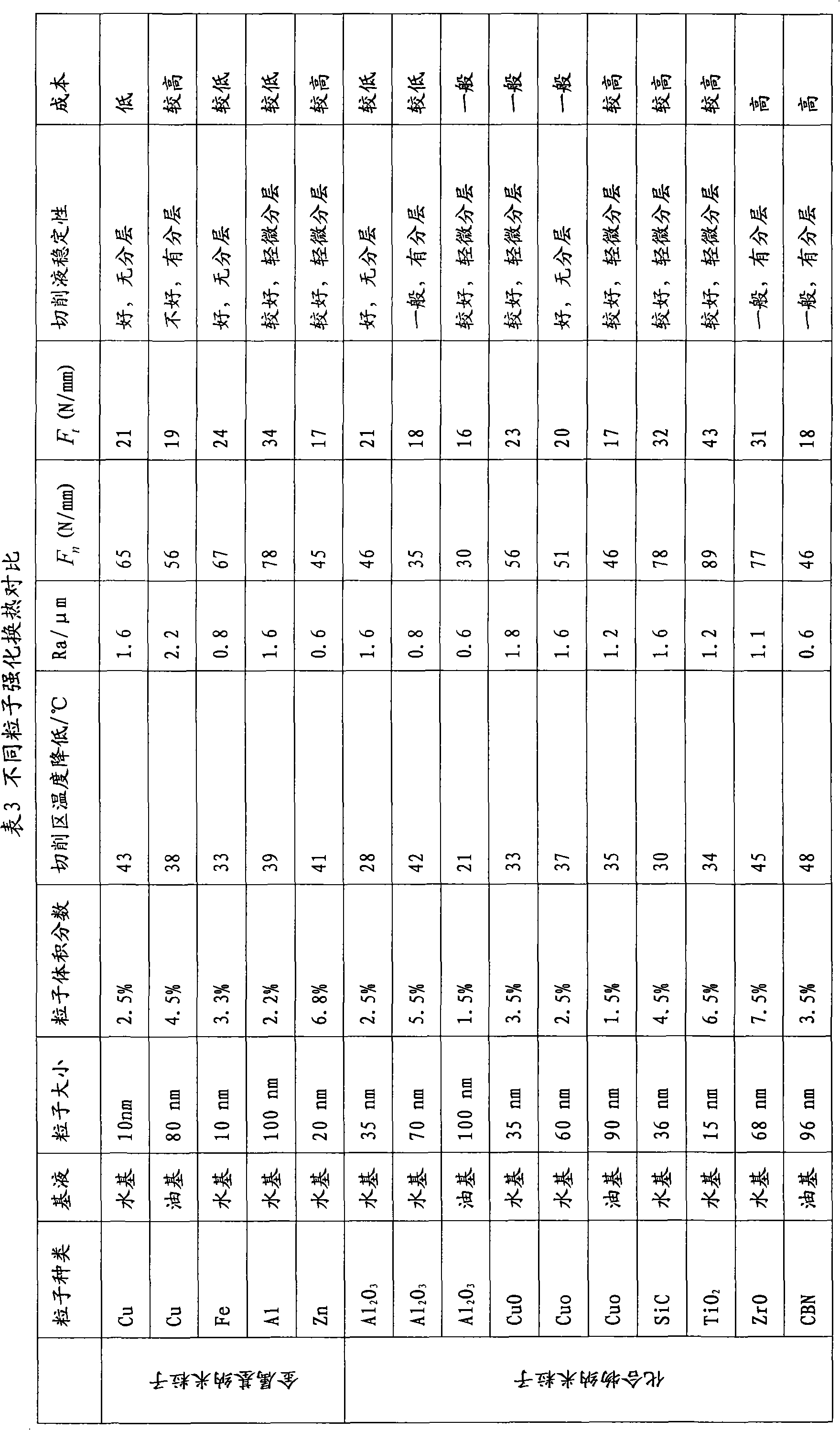

[0021] In order to verify the effect of nano cutting fluid, we have done a lot of experiments. Comparative experiments between nano cutting fluid and existing cutting fluid; formulation optimization of nano cutting fluid, including material, particle size, content, preparation method, etc. Now select two specific experiments and one experimental data statistical data to illustrate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to a machining method and a machining material, and relates to a process for milling a nickel-based alloy by nanoparticles at a high speed and nano cutting fluid. The nano cutting process is performed by applying nanoscale particles of a solid material to the high-speed cutting process of the nickel-based alloy. The nano cutting fluid is prepared by mixing the nanoscale particles of the solid material and liquid cutting fluid. Compared with a conventional water-based or oil-based cutting fluid, the nano cutting fluid has the advantages that the indexes such as the temperature of the cutting region, the surface roughness, the cutting resistance, the loss of the grinding tool and the like are all greatly reduced and the machining quality and the economic benefit are obviously improved; therefore, high application value and great market prospect can be achieved.

Description

technical field [0001] The invention belongs to the field of a mechanical processing method and a cutting fluid, that is, a nano particle high-speed milling nickel-based alloy process and a nano cutting fluid. Background technique [0002] Nickel-based alloy advanced materials are widely used in important parts of aero-engines such as compressor fan blades and casings due to their small specific gravity, high specific strength, good heat resistance and corrosion resistance. The processing quality of these key parts has a great impact on the engine The overall performance and efficiency impact is huge. Nickel-based alloys are typical difficult-to-machine materials. This type of workpiece material has the characteristics of large high-temperature strength, low thermal conductivity, severe work hardening, and easy chemical reactions with tool materials. This makes its machinability poor. The cutting temperature is high during processing, and the cutting tool is damaged quickly...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23C3/00C10M173/00C10M125/04

Inventor 李长河侯亚丽

Owner HIGH END EQUIP & RAIL TRANSIT TECH R & D CENT OF HAIAN TAIYUAN UNIV OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com