Method for preparing carbon micro-spheres by using coal as raw material

A technology of microspheres and raw materials, which is applied in the field of preparing carbon microspheres, can solve the problems of unsuitability for industrial scale production, limitations, high cost of raw materials and equipment, and achieve the effects of low cost of raw materials, easy control and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

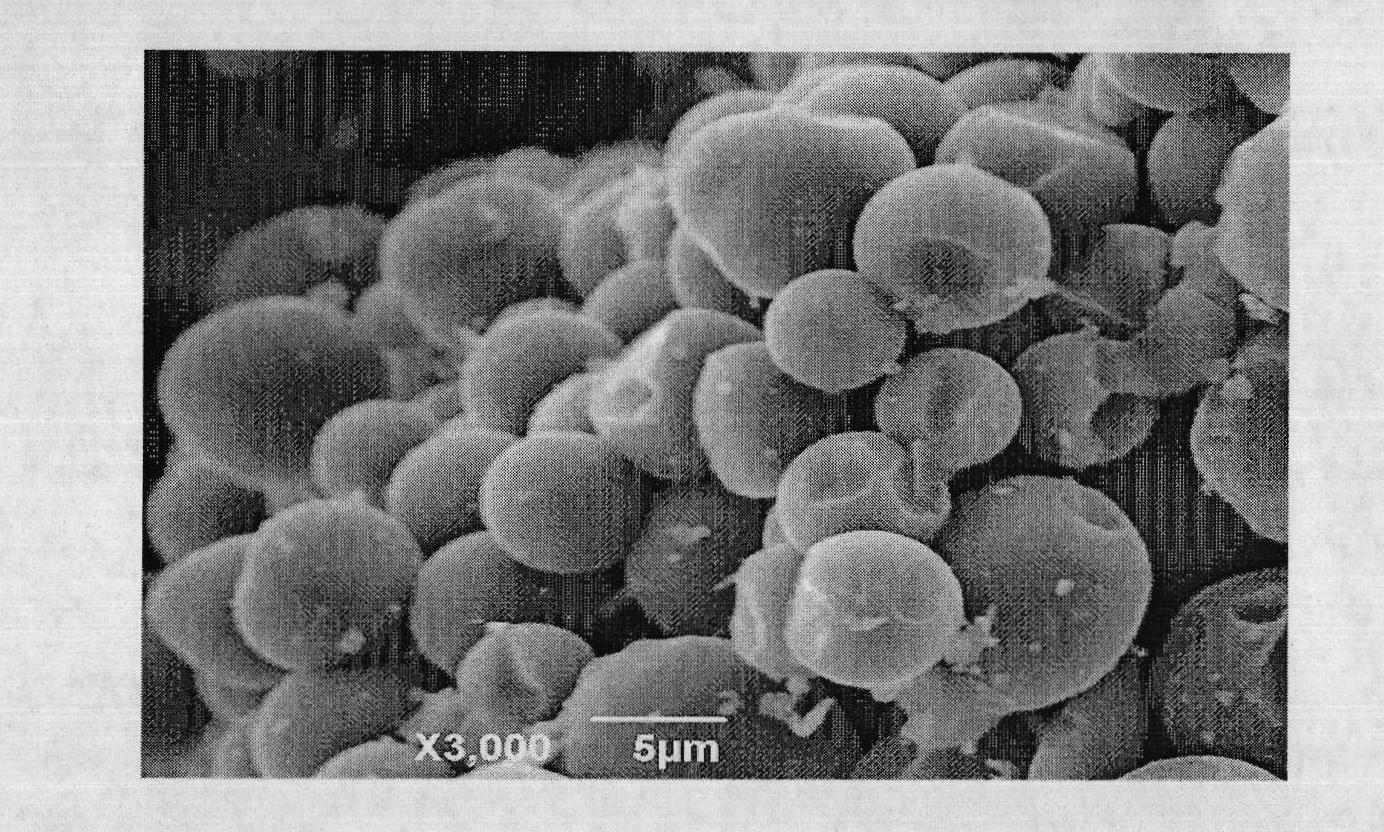

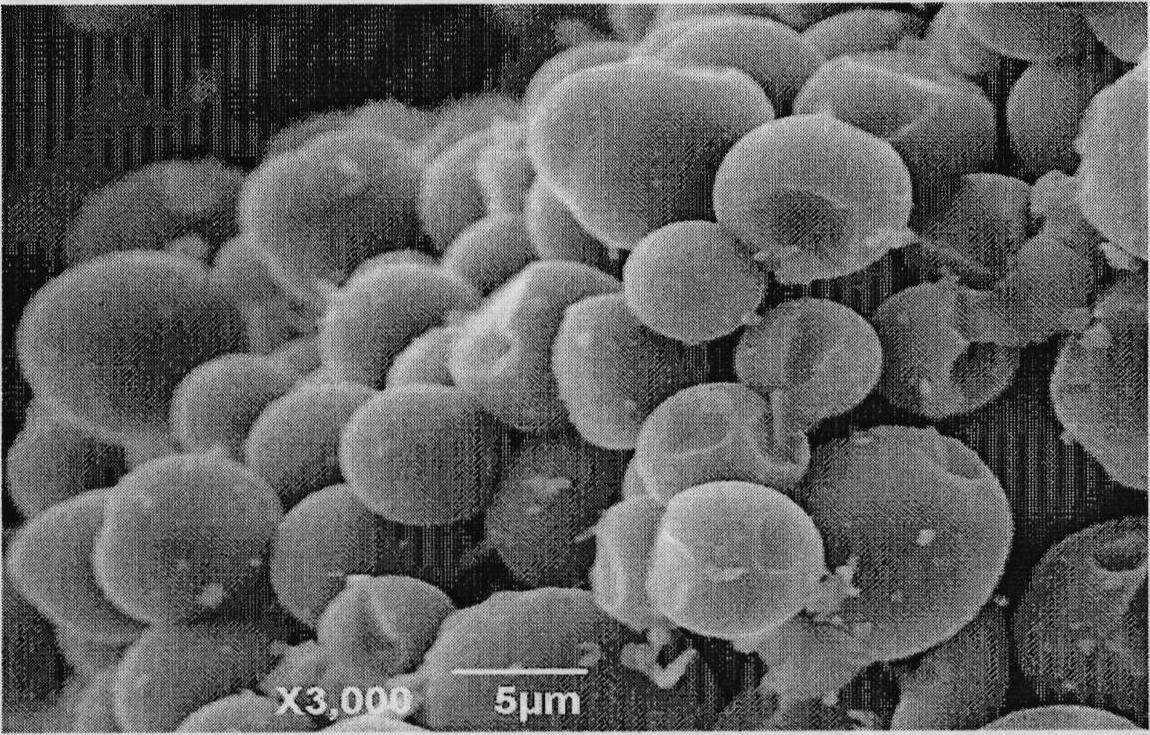

[0019] Example 1: Put 1 gram of Shengli coal, 1 gram of sodium hydroxide, and 5 milliliters of methanol into an autoclave, heat to 300° C., and react for 1 hour. After the kettle was cooled, the reaction product was extracted with tetrahydrofuran. Then, 1 gram of the tetrahydrofuran extraction product and 2 grams of cetyltrimethylammonium bromide were dissolved in 10 milliliters of ethanol, and 20 milliliters of water was added to mix the above solutions evenly. Then put it into a pressure valve and react at 600°C for 24 hours. After the kettle cools down, open the kettle, pour out the black product, wash it with absolute ethanol and distilled water, dry it in vacuum at 50°C for 5 hours, and finally grind it into a fine powder by mortar or ball mill to prepare carbon microspheres . Scanning electron micrographs are shown in the accompanying drawings.

Embodiment 2

[0020] Example 2: Put 1 gram of Shenhua coal, 0.5 gram of potassium hydroxide, and 2 milliliters of methanol into an autoclave, heat to 400° C., and react for 1 hour. After the kettle was cooled, the reaction product was extracted with tetrahydrofuran. Then 1 gram of tetrahydrofuran extraction product and 1 gram of dodecyltrimethylammonium bromide were dissolved in 5 milliliters of ethanol, and 20 milliliters of water was added to mix the above solutions evenly. Then put it into a pressure valve and react at 500°C for 24 hours. After the kettle cools down, open the kettle, pour out the black product, wash it with absolute ethanol and distilled water, dry it in vacuum at 80°C for 5 hours, and finally grind it into a fine powder by mortar or ball mill, which is the prepared carbon micron ball.

Embodiment 3

[0021] Example 3: Put 1 gram of Shengli coal, 0.1 gram of sodium hydroxide, and 15 milliliters of methanol into an autoclave, heat to 400° C., and react for 1 hour. After the kettle was cooled, the reaction product was extracted with tetrahydrofuran. Then 1 gram of tetrahydrofuran extraction product and 0.5 gram of cetyltrimethylammonium bromide were dissolved in 10 milliliters of ethanol, and then 20 milliliters of water was added to mix the above solution evenly. Then put it into a pressure valve and react at 500°C for 24 hours. After the kettle cools down, open the kettle, pour out the black product, then wash it with absolute ethanol and distilled water, dry it in vacuum at 60°C for 5 hours, and finally grind it into a fine powder by mortar or ball mill, which is the preparation of carbon microspheres .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com