Method for converting water solubility for reducing biotoxicity of luminous quantum dot synthesized by organic phase

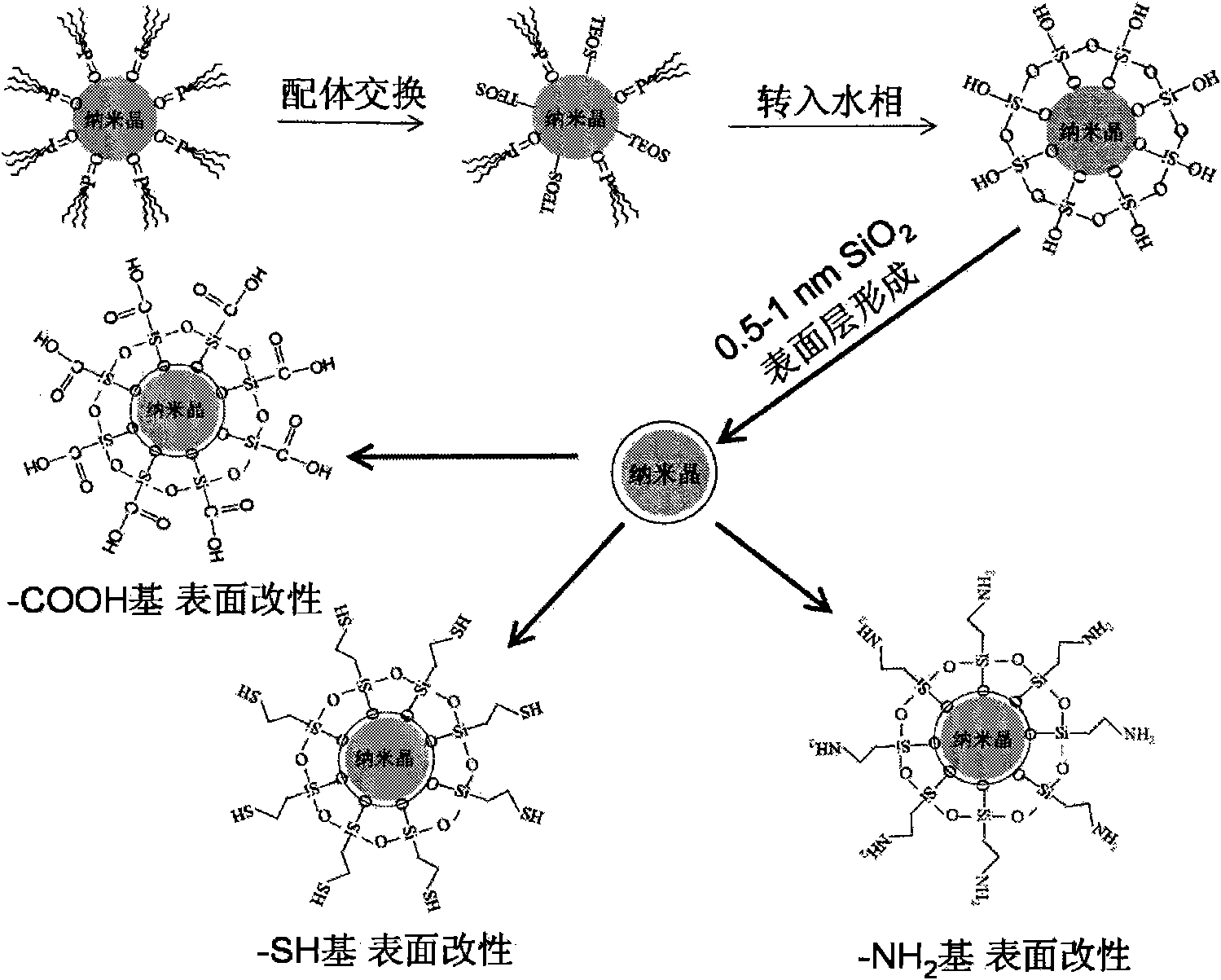

A biotoxic, luminescent quantum technology, applied in luminescent materials, chemical instruments and methods, nanotechnology, etc., can solve the problems of increasing the dynamic diameter of quantum dots, not reducing biological toxicity, and poor biological adaptability. Adjustable luminous color, wide excitation band, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

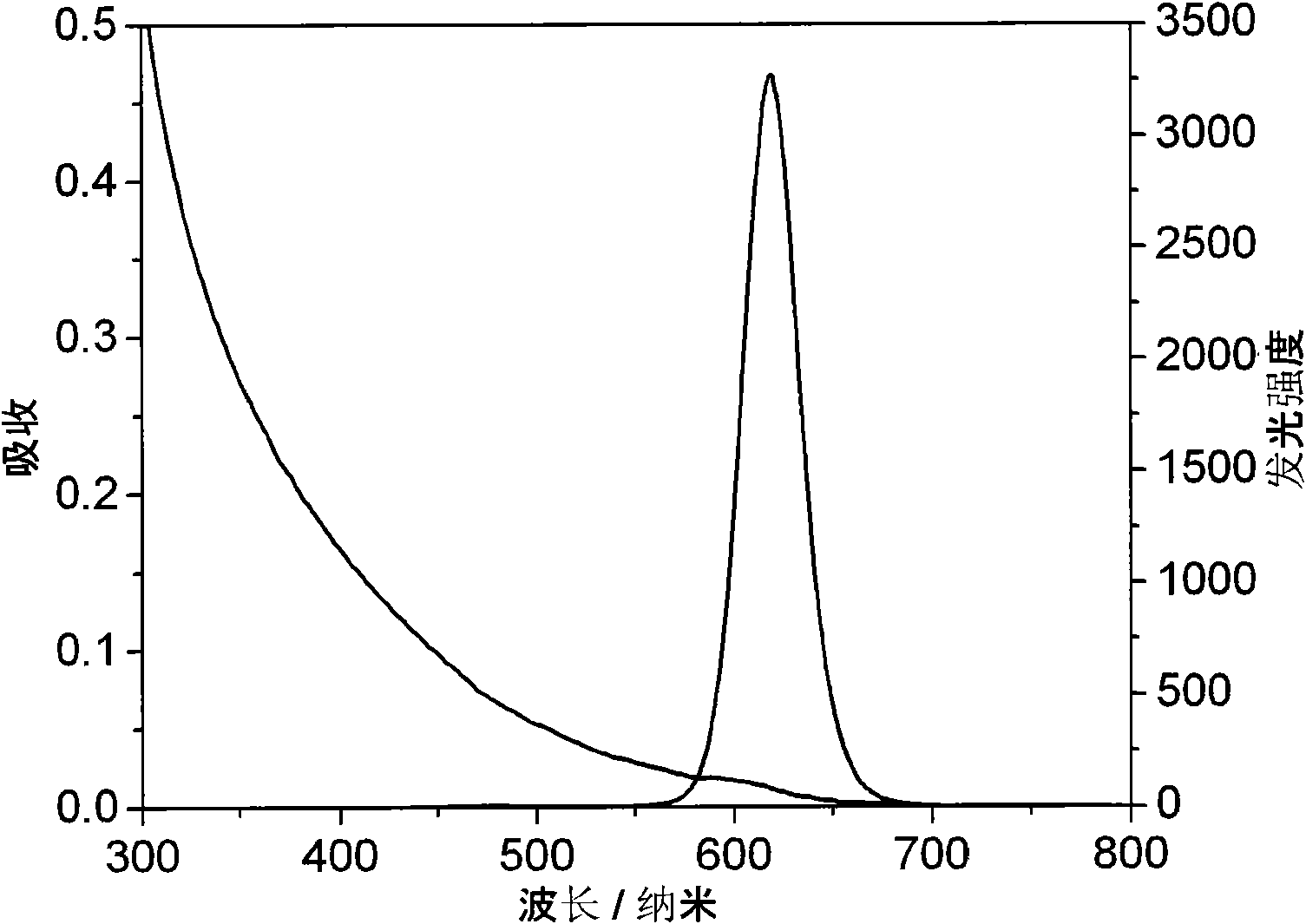

[0041] 1.1 Synthesis of CdSe quantum dots by organic method (see J.Phys.Chem.C, 2010, 114, 6205-6215 for details): First, put 500 mg of cadmium oxide, 2 g of dioctylamine, and 2 g of nonanoic acid in a three-necked flask Mix, keep vacuum at 100 degrees Celsius for 15 minutes, then heat to 200 degrees Celsius under nitrogen protection to dissolve cadmium oxide, then reduce to 120 degrees Celsius, put 10g of selenium in trioctylphosphine (TOP) solution (the mass concentration of selenium is 10% ) into quickly, in order to control the luminescent color, the growth time is 10 minutes, after separation, washing, and finally dispersed in toluene solution.

[0042] 1.2 Coating ZnS shell on the surface of CdSe quantum dots (see J.Phys.Chem.C, 2010, 114, 6205-6215 for details): newly prepared CdSe quantum dot toluene solution 4mL (quantum dot concentration 0.01mg / mL), Dioctylamine 2g, mixed with 0.05g dimethyl zinc (dissolved in 2mL trioctylphosphine (TOP)), then heated to 60 degrees C...

Embodiment 2

[0045] 2.1 Except that the growth time of quantum dots is 20 minutes, other steps and parameters are the same as in Example 1.1.

[0046] 2.2 Coating ZnS shell on the surface of CdSe quantum dots (see J.Phys.Chem.C, 2010, 114, 6205-6215 for details): newly prepared CdSe quantum dot toluene solution 4mL (quantum dot concentration 0.01mg / mL), Dioctylamine 2g, mixed with 0.07g dimethyl zinc (dissolved in 2.2mL trioctylphosphine (TOP)), then heated to 60 degrees Celsius, the TOP solution of 10g sulfur (the mass concentration of sulfur is 10%) Rapid injection, in order to control the luminescent color, the growth time is 0.8 hours. After the growth is completed, the unreacted liquid reactant is washed away with methanol, centrifuged, and then extracted with toluene to obtain CdSe / ZnS with an average particle size of 7.1nm. Dotted toluene solution.

[0047] 2.3 Dilute 0.5 mL of the newly synthesized CdSe / ZnS quantum dot toluene solution (quantum dot concentration 0.5 mg / mL) into 2 ...

Embodiment 3

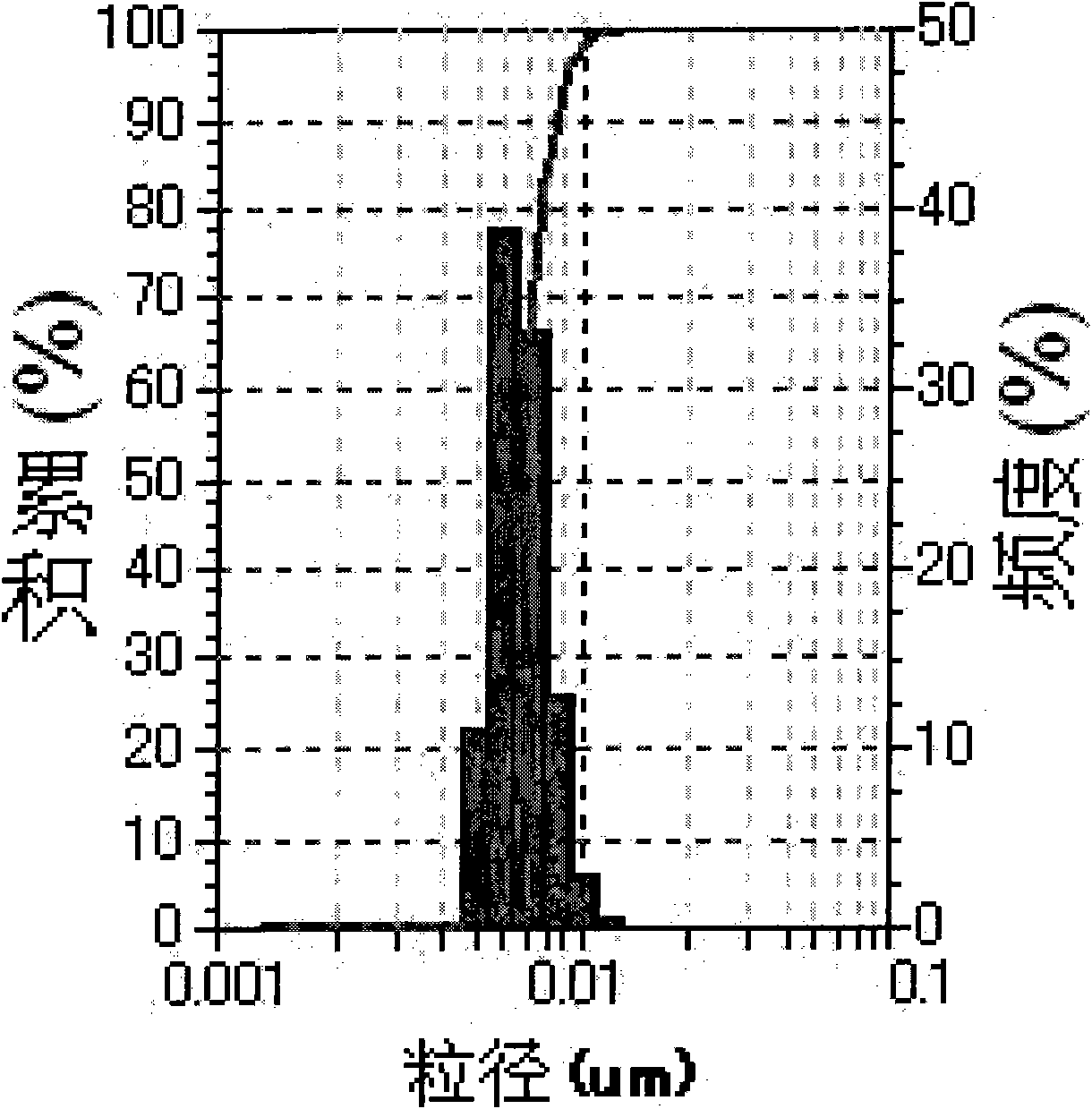

[0049] 3.1 The preparation method of CdSe / ZnS core-shell quantum dots is the same as that in Examples 1.1 and 1.2 above.

[0050] 3.2 Dilute 0.5 mL of the newly synthesized CdSe / ZnS quantum dot toluene solution (quantum dot concentration 0.5 mg / mL) into 2 mL of toluene, add 2 μL of methyl orthosilicate, and stir for 3 hours to obtain solution A; 1 μL of trimethyl Aminopropylsilane was added to a mixture containing 25ml of ethanol, 2mL of ammonia water with a mass concentration of 25%, and 1mL of water and stirred for 10 minutes to obtain solution B; mixed and stirred for 2 hours, and then centrifuged at 22000rpm After 20 minutes, the precipitate was dispersed in water to obtain water-soluble, amino-modified, SiO 2 Coated CdSe / ZnS quantum dots. The quantum dots can be connected with carboxyl groups on biomolecules by linking molecules for biomarking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com