Water generating method by utilizing separating membrane to enrich air water vapor and device thereof

A water production device and water vapor technology, applied in separation methods, drinking water devices, water supply devices, etc., can solve the problems of troublesome adsorbent regeneration process, increase the volume and weight of equipment, and bulky adsorption equipment, and achieve easy maintenance, no Corrosion problem, effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

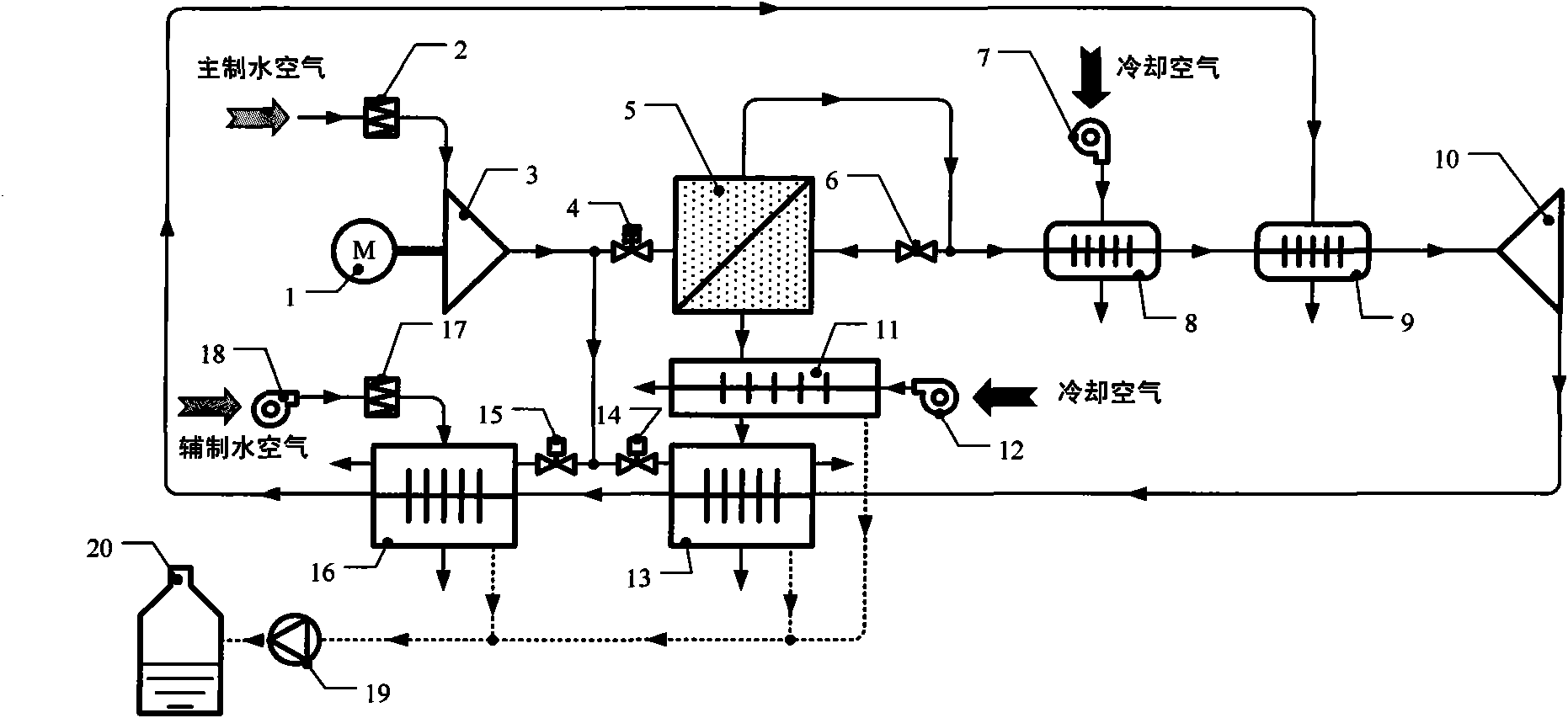

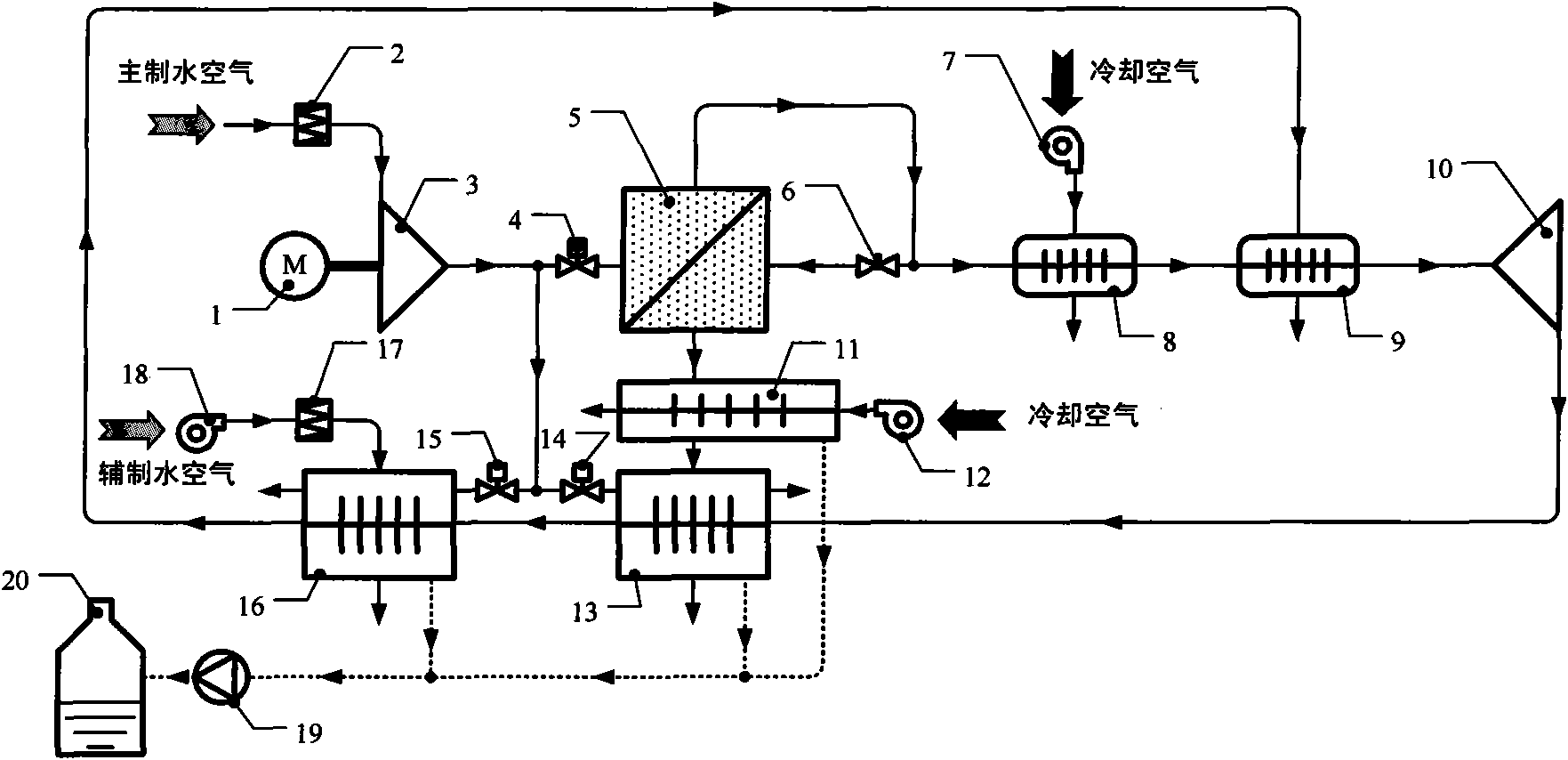

[0025] The accompanying drawings disclose a preferred embodiment of the present invention without limitation, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The method for producing water utilizing a separation membrane to enrich air water vapor according to the present invention comprises the following steps: (1) air pretreatment adopts an air filter and a compressor to remove impurities and compress air; (2) air water vapor The separation process uses the membrane dehumidification module 5 to dehumidify the compressed air processed in step (1) to obtain dehumidified air and water vapor on both sides of the membrane; Air is introduced into the water vapor permeation side of the membrane dehumidification module 5 in step (2), and the water vapor on the surface of the membrane wall is swept away to obtain high-humidity purge gas to realize the enrichment of air water vapor. The source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com