Power system of single-screw expansion engine as pneumatic automobile engine

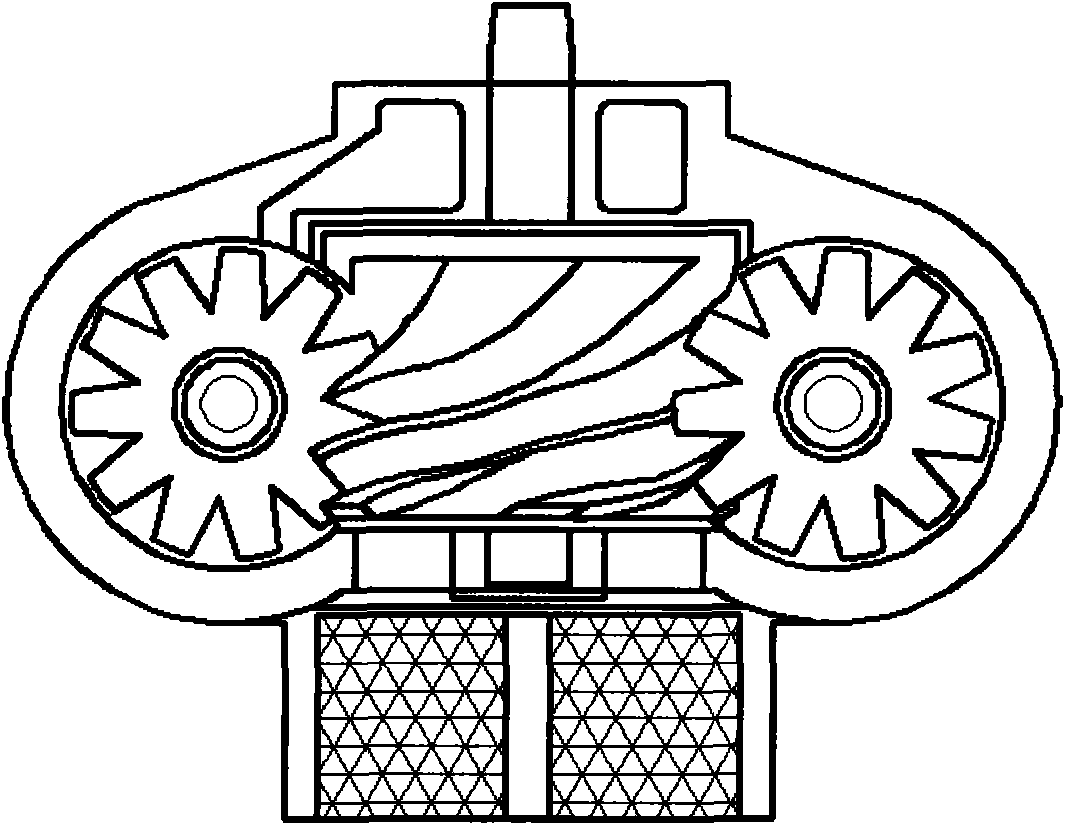

A pneumatic vehicle and power system technology, applied in the direction of machines/engines, combined engines, intermeshing engines, etc., can solve problems such as difficult control and complex structure of piston pneumatic engines, and achieve simple valve mechanism, small vibration, and easy The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

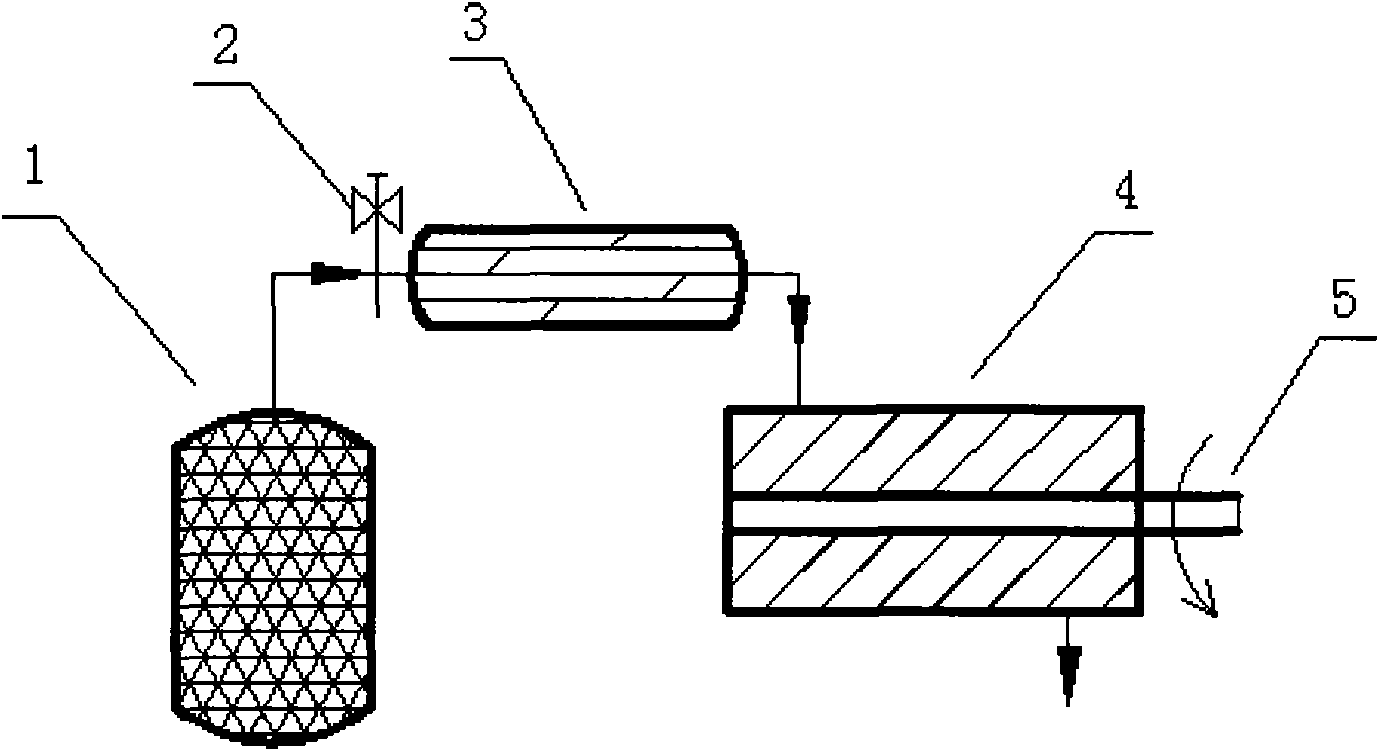

[0019] Scheme system see figure 2 , the present embodiment adopts the form of a single-stage expander, and the heating method can be hot water heating, air heating, or gas heating.

[0020] The pneumatic engine power system includes a high-pressure air bottle 1 used as a power source, a regulating valve 2 for working condition control, a heater 3 and a single-screw motor 4, and the air flowing out of the high-pressure air bottle 1 controls the compressed air through the regulating valve 2 After the flow rate and pressure reach the predetermined working conditions, it enters the heater 3 for heating, so as to increase the working temperature of the compressed air and gain the output work. After that, the pressurized high-temperature air enters the single-screw engine 4 to perform expansion work, and the mechanical work output shaft 5 output mechanical work.

Embodiment approach 2

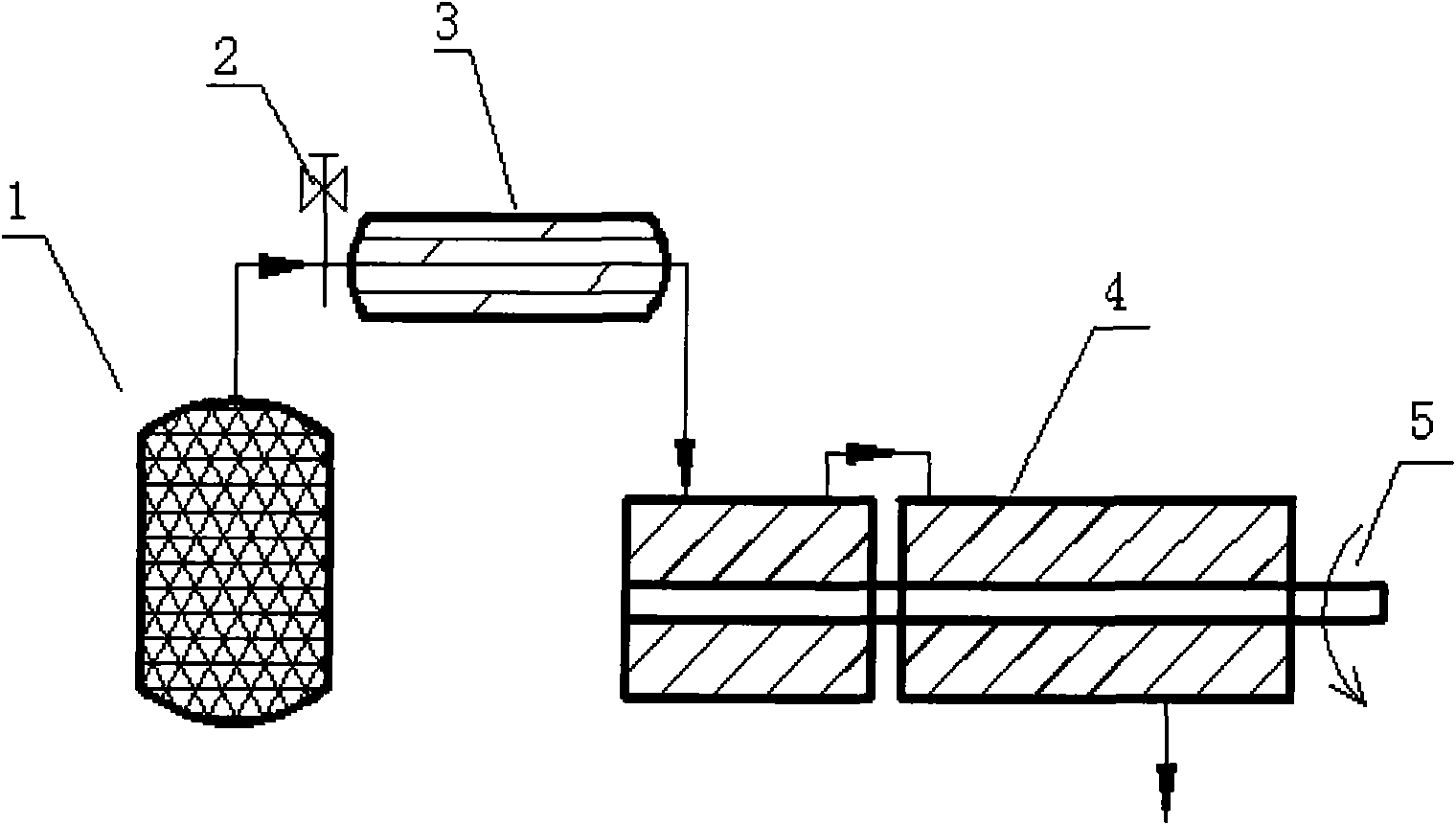

[0022] Scheme system see image 3 , The system of this embodiment adopts the form of two-stage expansion and first-stage heating, and the heating method can be hot water heating, air heating, or gas heating. Since the two-stage system has the optimal expansion ratio at different heating temperatures, it is necessary to select a single-screw expander that matches the corresponding optimal expansion ratio. The two-stage expansion work can increase the total expansion ratio and increase the power output. The connection mode of the two-stage expanders is designed to be in series, that is, the exhaust gas of the first-stage expander is used as the intake air of the second-stage expander, and the Coaxial output makes the structure more compact and easy to control. This system solution is mainly used in engines with medium power.

[0023] The pneumatic engine power system includes a high-pressure air bottle 1 used as a power source, a regulating valve 2 for working condition control...

Embodiment approach 3

[0025] Scheme system see Figure 4 , The system of this embodiment adopts the form of three-stage expansion and hierarchical heating, and the heating method can be hot water heating, air heating, or gas heating. Considering the problem of inter-stage distribution, it is necessary to select the optimal matching of the three-stage expansion ratio, and in order to improve work efficiency, the compressed air is heated before entering each stage of the expander, that is, the way to realize staged heating. The system scheme can realize relatively large power output, and is suitable for relatively high-power automobile engines.

[0026]The pneumatic engine power system includes a high-pressure air bottle 1 used as a power source, a regulating valve 2 for working condition control, a heater 3 and a single-screw motor 4, and the air flowing out of the high-pressure air bottle 1 controls the compressed air through the regulating valve 2 After the flow and pressure of the compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com