Method for treating pesticide residue sample in Chinese medicinal material before measurement

A treatment method and pesticide residue technology, which is applied in the field of determination of Chinese herbal medicines, can solve the problems of low degree of automation, low efficiency of extraction and purification, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

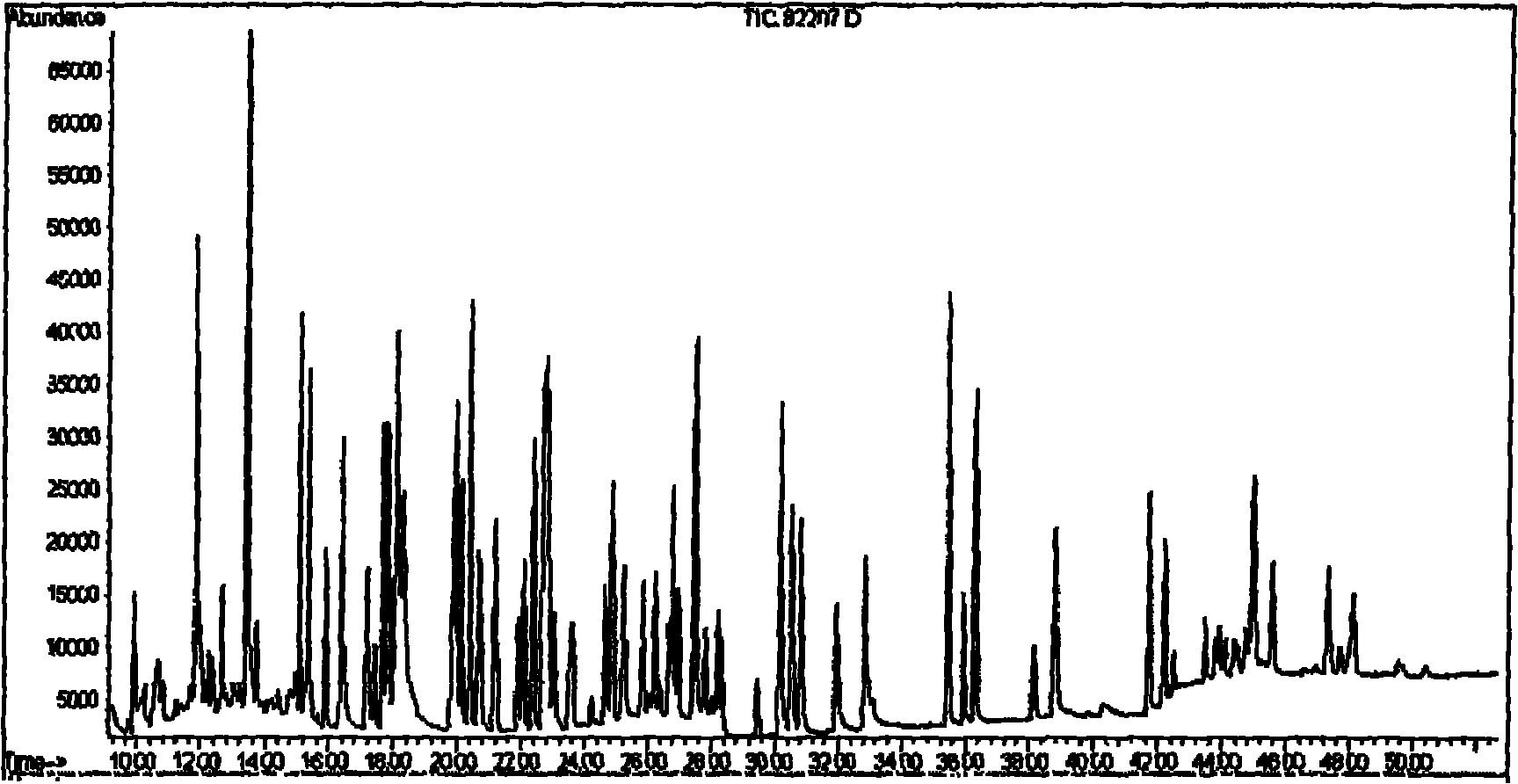

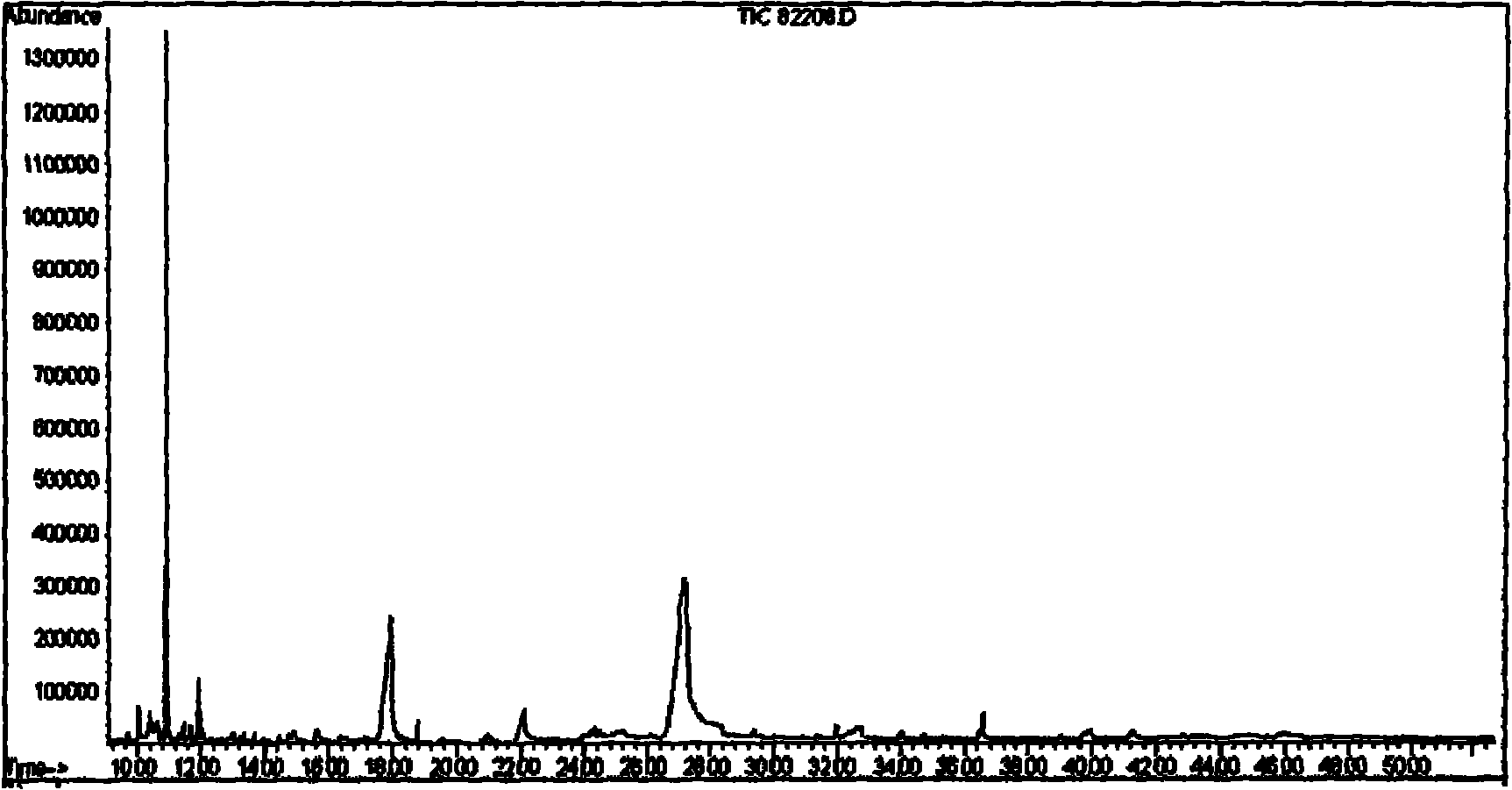

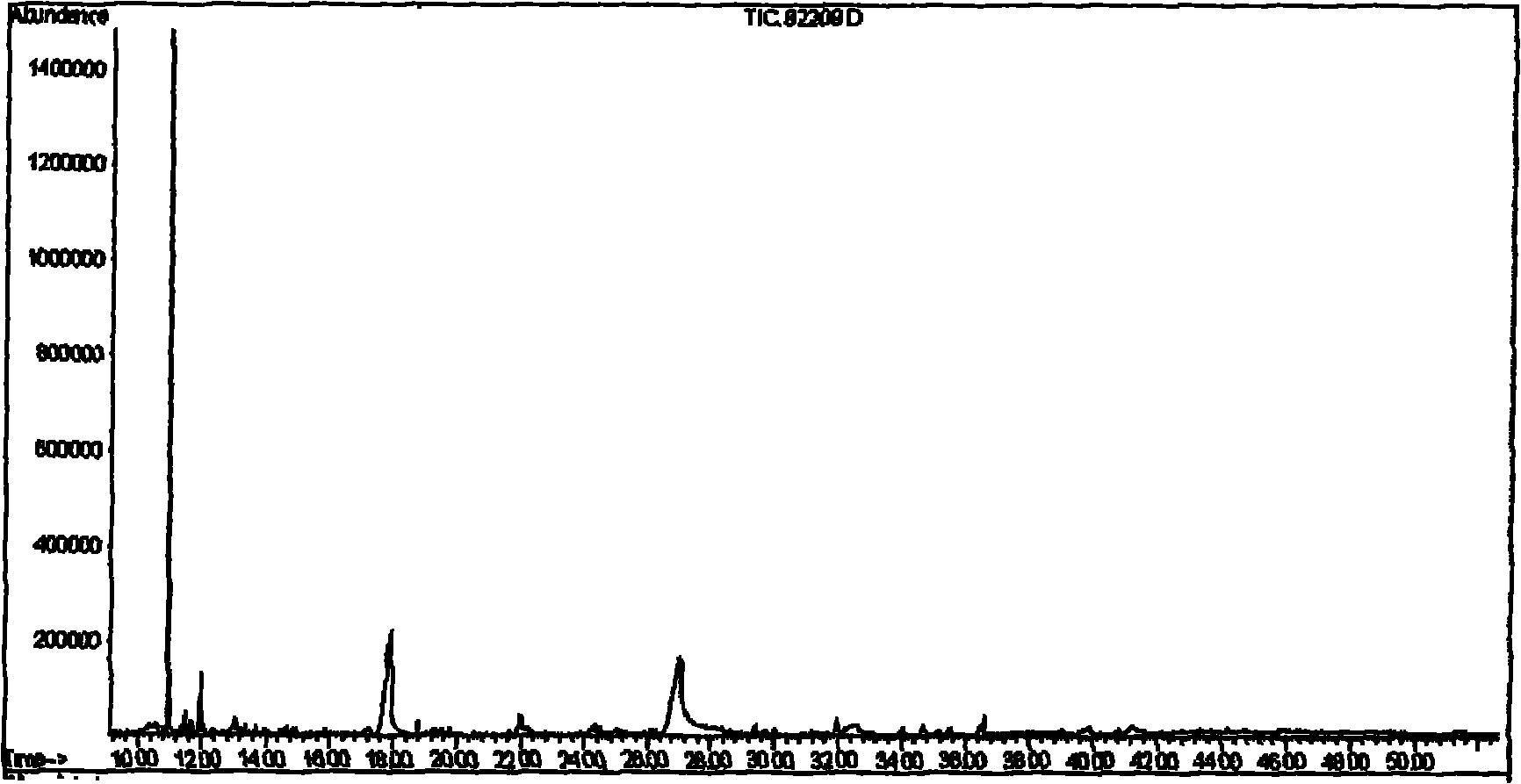

Image

Examples

Embodiment 1

[0050] (1) Crush the coix seed sample, pass through a 60-mesh sieve, dry at 60°C, and store in a desiccator;

[0051] (2) Accurately weigh 3 samples of 2.0g Coix seed, one of which is added with 0.1ml of 60 kinds of pesticides mixed standard, and let stand for 10 minutes, then mix the sample with 1g of diatomaceous earth evenly, add a piece of fiber to the bottom of the 11ml extraction cell Prime filter membrane, and then load the mixed sample from the bottom for accelerated solvent extraction;

[0052] (3) Static extraction at a temperature of 100°C, acetone:n-hexane (1:9, v / v), and a pressure of 1500psi for 5 minutes, and extraction for 2 cycles;

[0053] (4) Wash the extraction tank with a solvent equivalent to 60% of the extraction tank, and finally purge it with nitrogen for 60s. Collect the extract, concentrate on a rotary evaporator to near dryness, blow nitrogen to dryness, add 2ml of acetonitrile to dissolve for purification.

[0054] (5) Purification: Weigh 0.2g PSA, 0.2g C...

Embodiment 2

[0056] (1) Crush the sample of Atractylodes japonicus, pass a 100-mesh sieve, dry at 80°C, and store in a desiccator;

[0057] (2) Accurately weigh 3 2.0g atractylodes samples, one of which is added with 0.1ml of 60 kinds of pesticide mixed standards, and let it stand for 10 minutes, then mix the sample with 1g diatomaceous earth evenly, and add a piece of cellulose at the bottom of the 11ml extraction cell Filter membrane, and then load the mixed sample from the bottom for accelerated solvent extraction;

[0058] (3) Static extraction for 10 minutes at a temperature of 100°C, acetone:n-hexane (1:9, v / v) and a pressure of 2000 psi, and extraction for 4 cycles;

[0059] (4) Wash the extraction tank with 75% solvent equivalent to the extraction tank, and finally purge it with nitrogen for 60s. The extract was collected, concentrated to near dryness on a rotary evaporator, nitrogen was blown to dryness, and 2ml of solvent (volume ratio of acetone to n-hexane 1:1) was added to dissolve ...

Embodiment 3

[0062] 1. Accelerated solvent extraction: accurately weigh out 3 2.0g ginseng samples, one of which is added with 0.1ml of 60 kinds of pesticide mixed standards, and let stand for 10 minutes, then mix the sample with 1.5g diatomaceous earth evenly, 11ml extraction cell at the bottom Add a piece of cellulose filter membrane, and then load the mixed sample from the bottom. Then perform accelerated solvent extraction. Static extraction is carried out at a temperature of 80°C, acetone:n-hexane (1:9, v / v), and a pressure of 2000psi for 8 minutes. The extraction is carried out for 3 cycles. The extraction tank is washed with a solvent equivalent to 70% of the extraction tank, and finally Purge with nitrogen for 60 s. The extract was collected, concentrated to near dryness on a rotary evaporator, nitrogen was blown to dryness, and 2ml of a mixed solvent of acetone and n-hexane (1:1) was added to dissolve it for purification.

[0063] Purification: Weigh 0.2g PSA, 0.2g C18, 0.3g anhydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com