Nanometer mineral substance air purifier

An air filter and mineral technology, applied in the field of nano-mineral air filter, can solve the problems of high energy consumption, high pollution, and hazards of activated carbon, and achieve the effects of prolonging service life, good use effect, and health protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

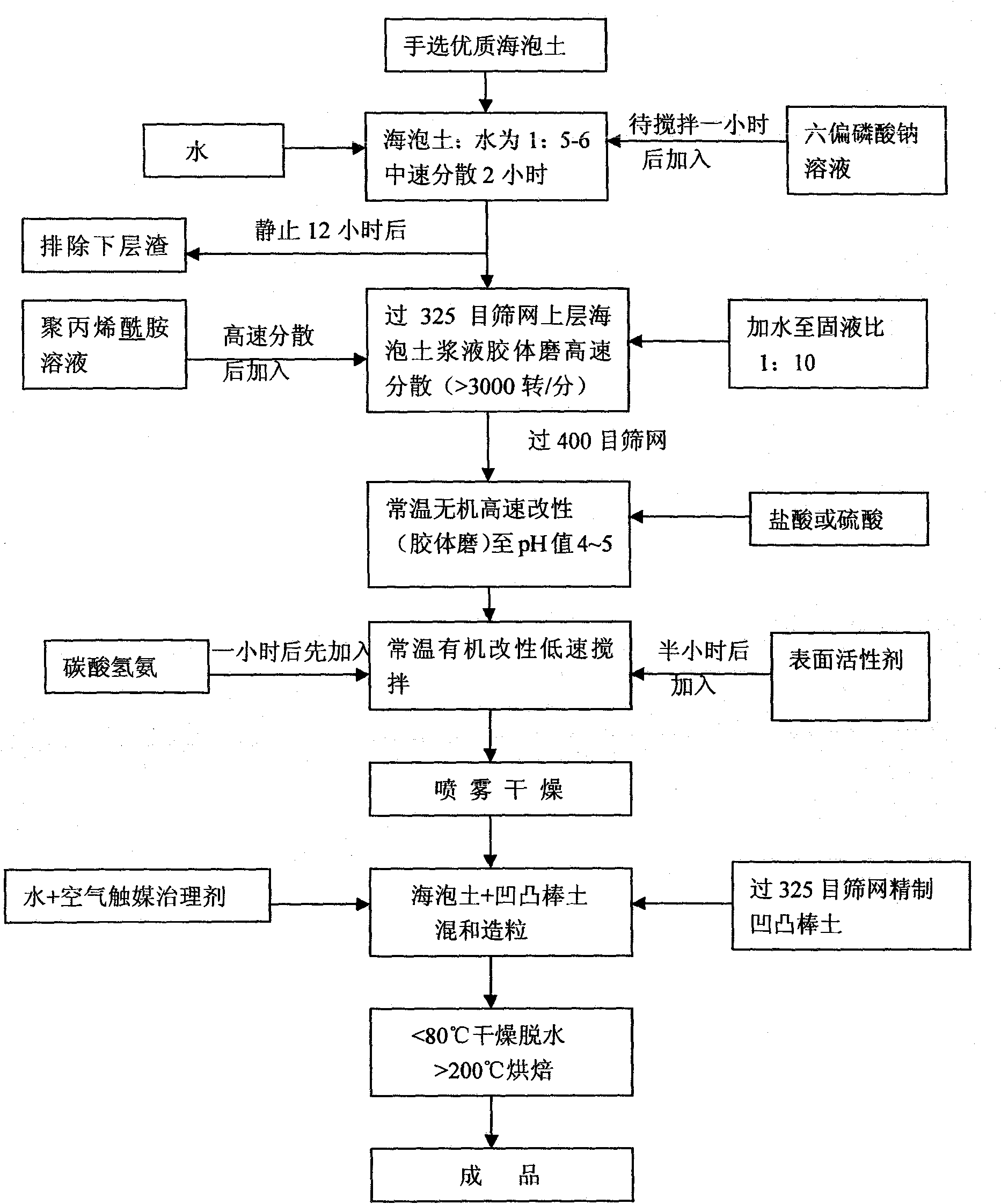

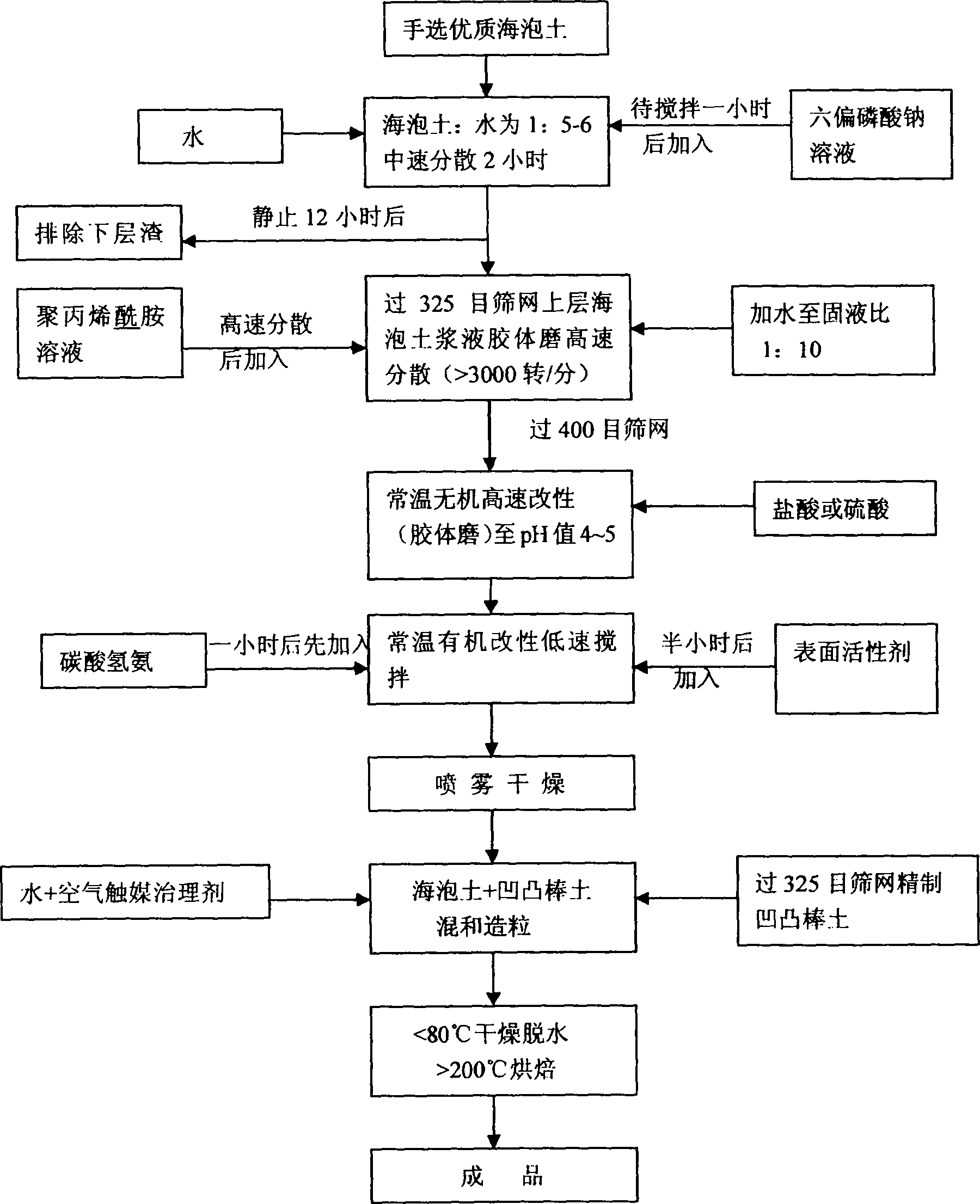

[0030] The preparation method of nano mineral air cleaner of the present invention comprises the following steps:

[0031] Step 1. Add 70-90 parts of sepiolite into water and stir to disperse. After stirring and dispersing, add a solution containing 1-3 parts of sodium hexametaphosphate;

[0032] Step 2, statically settle the mixed liquid, and then remove the lower layer of dross;

[0033] Step 3, pass the obtained sepiolite slurry through a 300-350 mesh screen, and disperse it through a colloid mill at a high speed greater than 3000 rpm, and add a solution containing 0.0001-0.001 part of polyacrylamide after high-speed dispersion;

[0034] Step 4. Pass the obtained mixed liquid through a 375-425 mesh screen, then add 1-2 parts of hydrochloric acid or sulfuric acid at room temperature for high-speed inorganic modification, and adjust the pH value of the solution to 4-5;

[0035] Step 5. Carry out organic modification at room temperature, add 1-5 parts of ammonium bicarbonate ...

Embodiment 1

[0040] As shown in Figure 1, the preparation method of the nano mineral air filter of the present embodiment comprises the following steps:

[0041] Step 1. Select high-quality sea foam by hand, then add 70-90 parts of sea foam to water and stir to disperse. The weight-number ratio of sea foam to water is 1:5 to 1:6, and sea foam to water Stir and disperse at high speed for two hours; add a solution containing 1-3 parts of sodium hexametaphosphate after stirring and dispersing for one hour;

[0042] Step 2. Statically settle the mixed liquid for 8 to 14 hours, preferably 12 hours in this embodiment, and then remove the lower layer of dross;

[0043] Step 3, pass the obtained sepiolite slurry through a 300-350 mesh screen, preferably a 325 mesh screen in this embodiment, and disperse it through a colloid mill at a high speed greater than 3000 rpm. After high speed dispersion, add the 0.0001-0.001 part of polyacrylamide solution, and then add water until the solid-liquid volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com