Selective laser melting (SLM) molding method for magnesium alloy stent

A technology for selective laser melting and magnesium alloy blood vessels, which is applied in the field of magnesium alloy parts manufacturing, can solve the problems of low manufacturing accuracy, toxic release, low yield, etc., and achieves high shape and dimensional accuracy, simple processing procedures, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

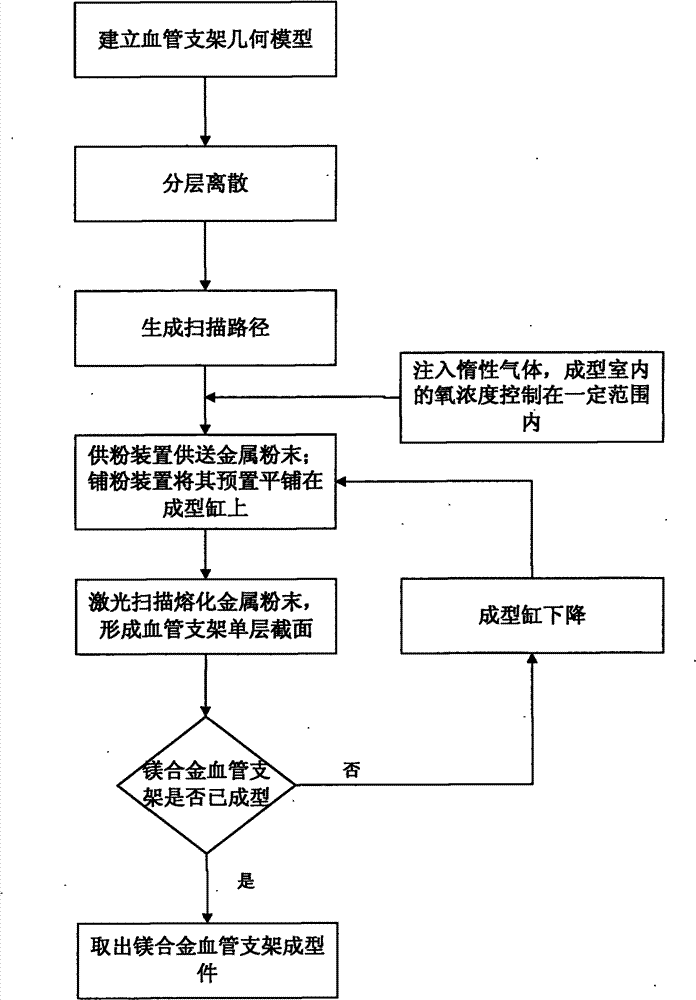

[0034] Such as figure 1 As shown, the selective laser melting forming method of the magnesium alloy vascular stent specifically includes the following steps:

[0035] (1) Establish the geometric model of the vascular stent in the host computer, perform layered discretization on the geometric model, and generate a scanning path according to the geometric contour;

[0036] (2) inject inert gas into the molding chamber, and control the oxygen concentration in the molding chamber within a certain concentration range;

[0037] (3) The powder supply device supplies the metal powder to the molding cylinder in the molding chamber, and the powder spreading device pre-spreads it on the molding cylinder;

[0038] (4) The metal powder is scanned by laser, and the laser is emitted and transmitted by the laser, forming a focused spot on the processing plane of the metal powder, melting the metal powder, and forming a single-layer cross-section of the vascular stent;

[0039] (5) Determine...

Embodiment 2

[0054]This embodiment is the same as Embodiment 1 except for the following features: the powder feeding device is a powder feeding cylinder, the powder spreading device is a scraper, and the step (4) uses a fiber laser to emit laser light. In the step (2), the injected inert gas is high-purity nitrogen with a purity of 99.99%.

[0055] In the step (3), before the metal powder is placed on the base plate of the molding cylinder, it is first heated by a heating wire arranged under the base plate or in the powder spreading device, so that the temperature of the metal powder reaches 130°C.

[0056] In the step (2), the oxygen concentration in the molding chamber is controlled within a concentration range of 8 ppm.

[0057] The average particle size of the magnesium alloy powder is 5 μm.

[0058] The diameter of the focused light spot in the step (4) is 50 μm.

[0059] In the step (4), the laser performs interlayer staggered scanning on the metal powder, and at the same time scan...

Embodiment 3

[0062] This embodiment has the same characteristics as Embodiment 1 except for the following features: in the step (3), before the metal powder is preset to the substrate of the molding cylinder, it is first heated by a heating wire arranged under the substrate or in the powder spreading device , so that the temperature of the metal powder reaches 120°C.

[0063] In the step (2), the injected inert gas is high-purity nitrogen with a purity of 99.999%.

[0064] In the step (2), the oxygen concentration in the molding chamber is controlled within a concentration range of 6 ppm.

[0065] The average particle size of the magnesium alloy powder is 10 μm.

[0066] The diameter of the focused light spot in the step (4) is 40 μm.

[0067] In the step (4), the laser performs interlayer staggered scanning on the metal powder, and at the same time scans the outline of the part, the scanning speed of the laser outline is 130mm / s; the power of the laser is 180W; the The scanning speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com