Method for treating domestic sewage by applying light ceramic suspended filler moving bed

A technology of suspended filler and lightweight ceramsite, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor impact load resistance of biofilm and phosphorus removal effect Poor, semi-soft filler entanglement and other problems, to achieve the effect of facilitating general application and promotion, increasing biodegradability, and increasing the speed of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

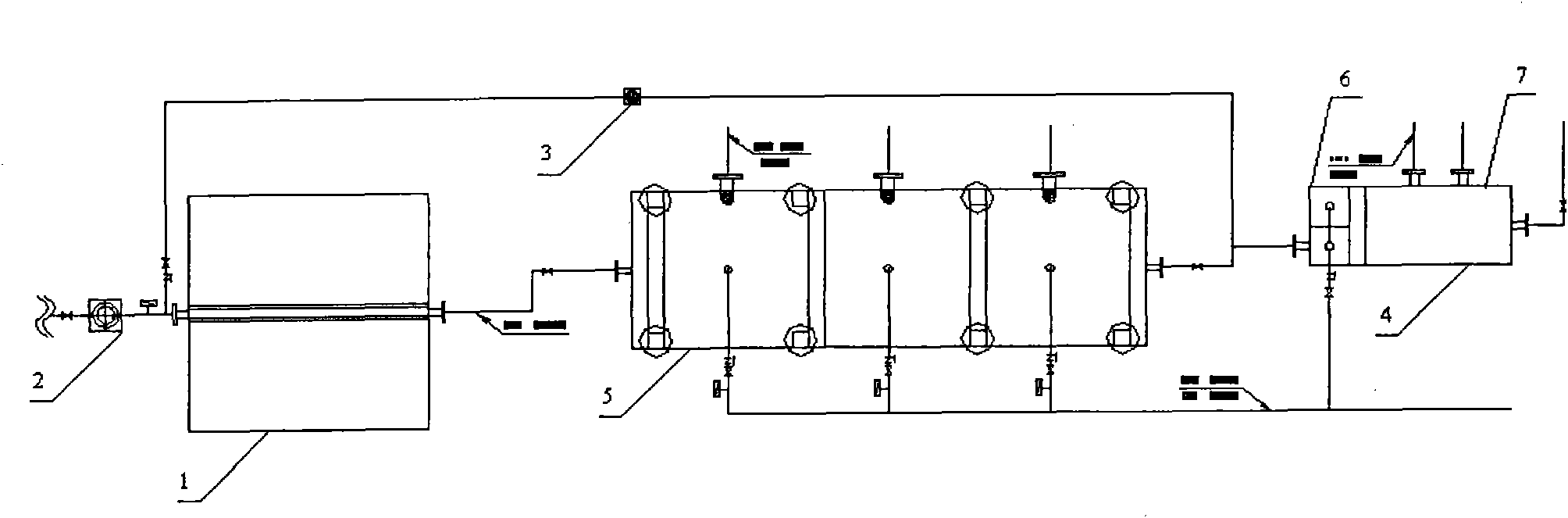

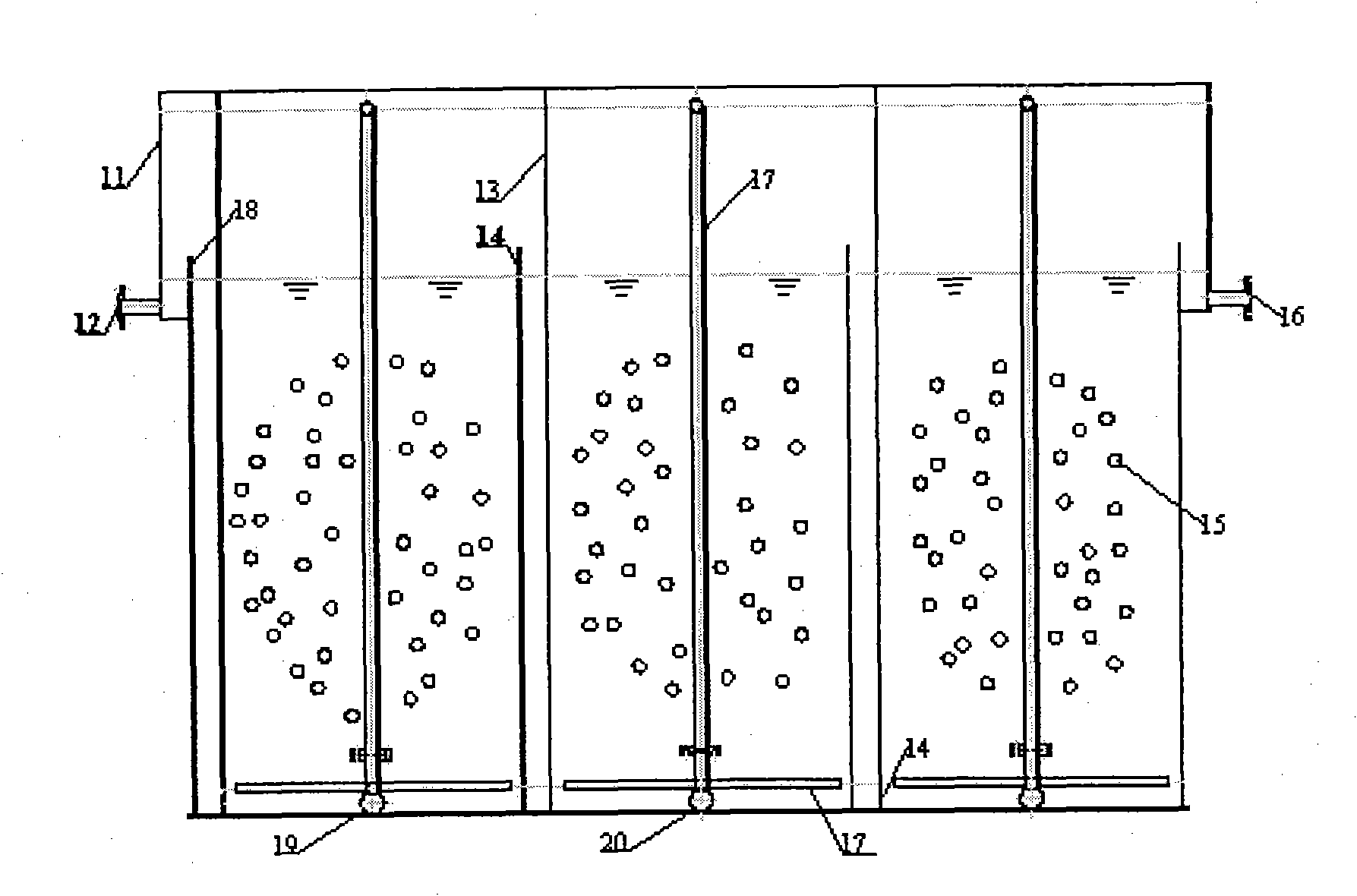

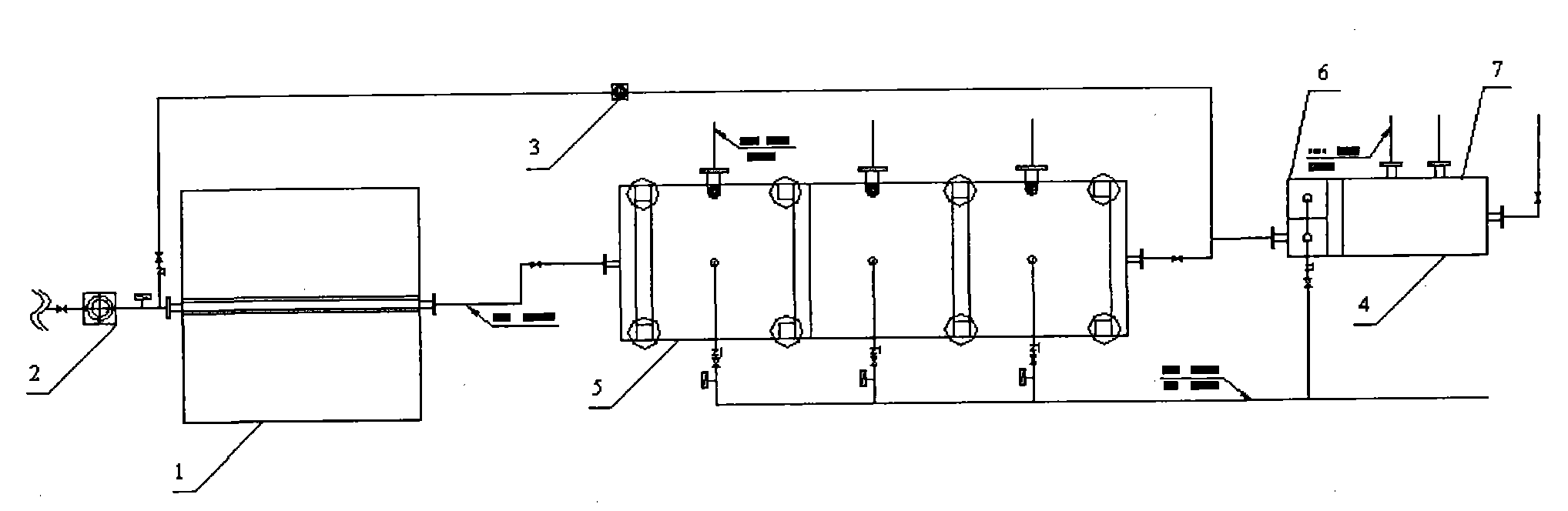

Embodiment 1

[0031] Under the condition of water temperature of 25-29℃, the urban sewage from a certain place in the south is pumped into the hydrolytic acidification tank 1 with a filling rate of 60%. The effective volume of the hydrolytic acidification tank 1 is 6.75m 3 , the hydrolytic acidification tank 1 is built with asbestos tiles with rough surface, the filling rate is 30%, the built-in plastic semi-soft filler, the filling rate is 30%, and the residence time is 6.0h; the water supernatant from the hydrolytic acidification tank enters the suspended packing moving bed 5, ( Filler 15 is lightweight ceramsite filler, spherical in appearance, particle size 8-12mm, bulk density of ceramsite 350-400kg / m 3 , the particle density is 600~700kg / m 3 , the porosity is about 40%, the cylinder compressive strength is about 1.0Mpa, the water absorption rate is about 12% in 1h, and the specific surface area is about 3.5-4.0cm 2 / g, providing a habitat with a relatively large specific surface area...

Embodiment 2

[0034] Under the condition of water temperature of 25-29℃, the urban sewage from a certain place in the south is pumped into the hydrolytic acidification tank 1 with a filling rate of 60%. The effective volume of the hydrolytic acidification tank 1 is 6.75m 3 , the hydrolytic acidification tank 1 has built-in asbestos tiles with rough surface, the filling rate is 30%, and the built-in plastic semi-soft filler, the filling rate is 30%, and the residence time is 5.0h; the effluent supernatant of the hydrolytic acidification tank enters the suspended packing moving bed 5, ( Filler 15 is lightweight ceramsite filler, spherical in appearance, particle size 8-12mm, bulk density of ceramsite 350-400kg / m 3 , the particle density is 600~700kg / m 3 , the porosity is about 40%, the cylinder compressive strength is about 1.0Mpa, the water absorption rate is about 12% in 1h, and the specific surface area is about 3.5-4.0cm 2 / g, providing a habitat with a relatively large specific surface ...

Embodiment 3

[0037] Under the condition of water temperature of 25-29℃, the urban sewage from a certain place in the south is pumped into the hydrolytic acidification tank 1 with a filling rate of 60%. The effective volume of the hydrolytic acidification tank 1 is 6.75m 3 , the hydrolytic acidification tank 1 is built with asbestos tiles with rough surface, the filling rate is 30%, the built-in plastic semi-soft filler, the filling rate is 30%, and the residence time is 4.0h; the water supernatant from the hydrolytic acidification tank enters the suspended packing moving bed 5, ( Filler 15 is lightweight ceramsite filler, spherical in appearance, particle size 8-12mm, bulk density of ceramsite 350-400kg / m 3 , the particle density is 600~700kg / m 3 , the porosity is about 40%, the cylinder compressive strength is about 1.0Mpa, the water absorption rate is about 12% in 1h, and the specific surface area is about 3.5-4.0cm 2 / g, providing a habitat with a relatively large specific surface area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com