Method for preparing gasoline from liquefied gas through aromatization and fixed bed reactor

A fixed-bed reactor, liquefied gas technology, applied in the petroleum industry, liquid hydrocarbon mixture production and other directions, can solve problems such as unfavorable production operations, shortened catalyst single-pass life, increased equipment investment and maintenance costs, etc. The effect of relieving market pressure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

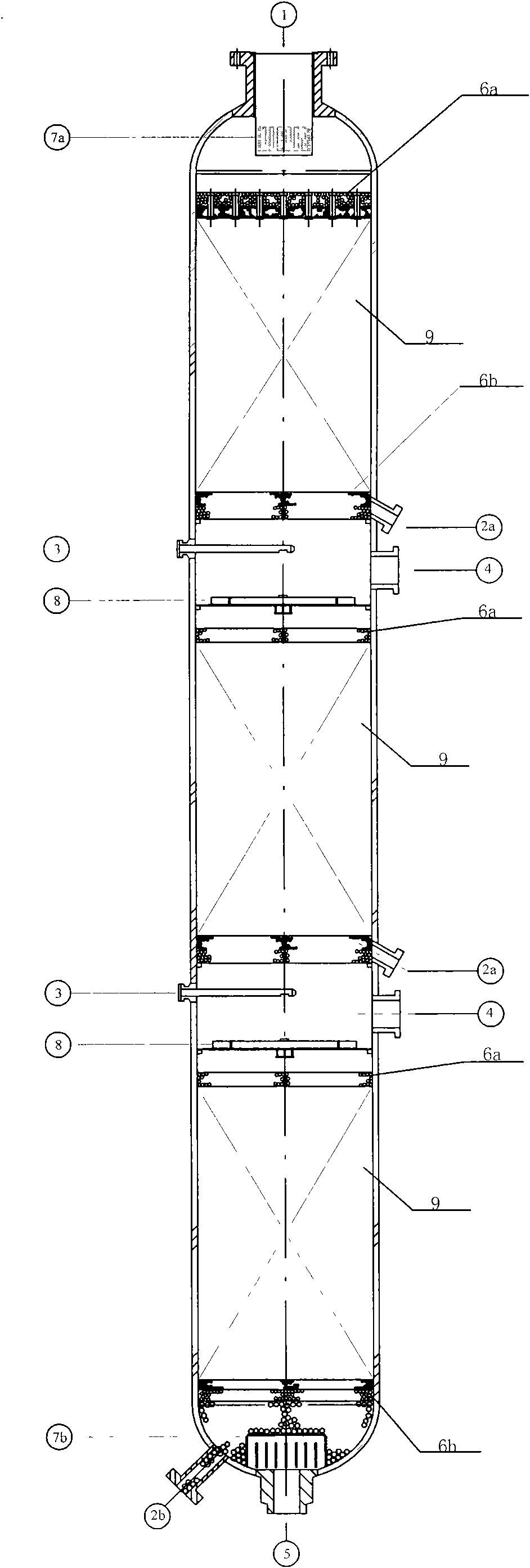

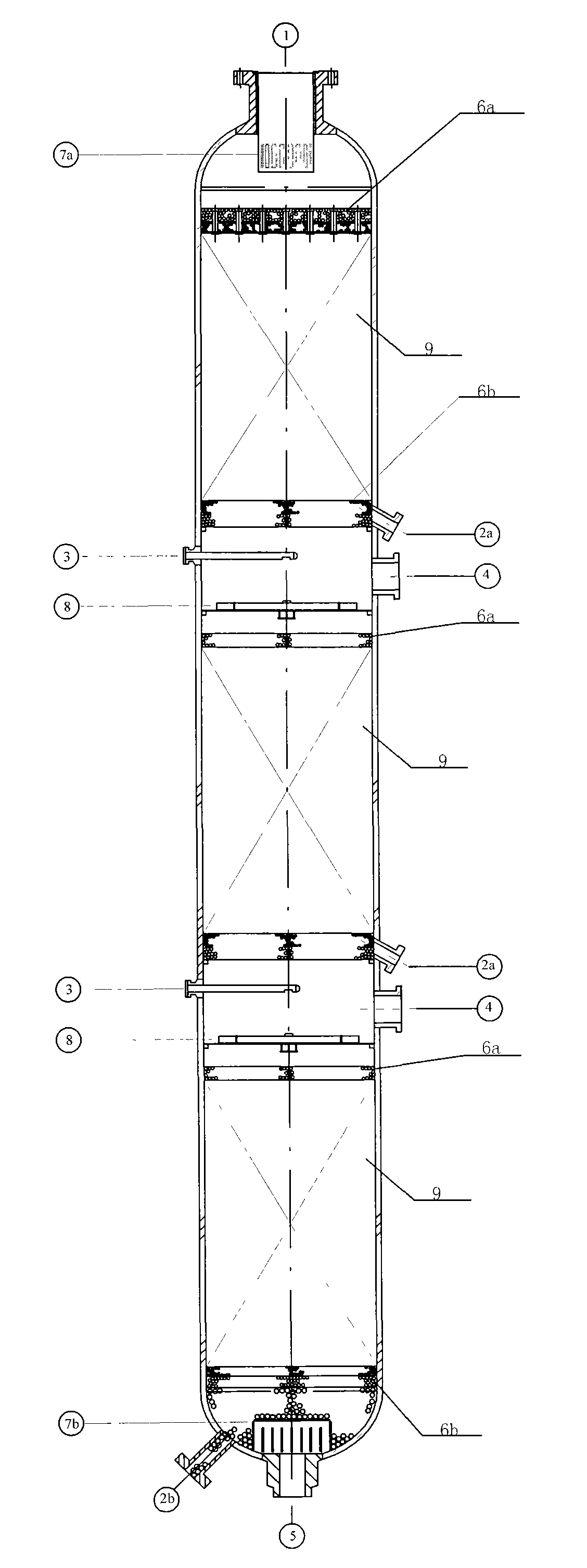

[0016] The process of producing high-octane gasoline by aromatization of liquefied gas consists of three parts: raw material pretreatment, cyclic reaction and regeneration, and absorption and stabilization; the liquefied gas raw material is first washed with water to remove impurities such as methanol, dimethyl ether, and alkali nitrogen, and then passes through a heat exchanger. After the heating furnace is heated to about 300 ℃, it enters the fixed-bed reactor and reacts at 280-410 ℃; the reacted product is separated by the absorption stabilization system to obtain high-octane gasoline, liquefied gas and other products, A small amount of dry gas is by-produced; after the reaction is carried out for a period of time, with the increase of the coking amount of the catalyst in the reactor, when the product quality or product distribution cannot meet the requirements, it means that the catalyst is saturated, the reaction needs to be stopped, and high temperature nitrogen is used in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com