Tin-bismuth-silver series lead-free solder and preparation method

A lead-free solder, tin-bismuth technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of declining product competitiveness and increasing solder production costs, and achieve low product cost and high tensile strength. The effect of strength, good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

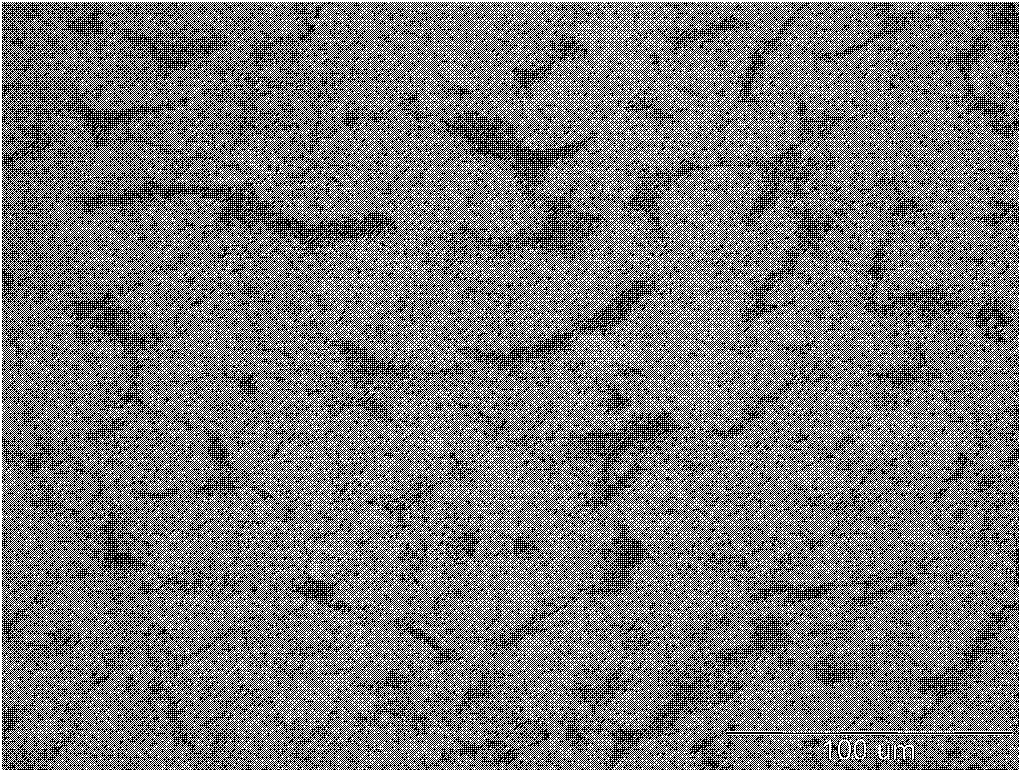

[0021] Heat tin, bismuth and silver with a purity of 99.99% in a mass ratio of 98.9:1:0.1 in a vacuum melting furnace under the protection of argon to 1100°C to melt, and at the same time add magnetic stirring to make the alloy composition uniform, and then water-cooled and solidified . Then the alloy is turned over and reheated to 500° C. to melt, and at the same time, it is magnetically stirred and water-cooled, so that the Sn-1%Bi-0.1%Ag lead-free solder is obtained by repeating this at least four times. Its microstructure is as figure 1 As shown, the particles are Ag 3 Sn phase.

Embodiment 2

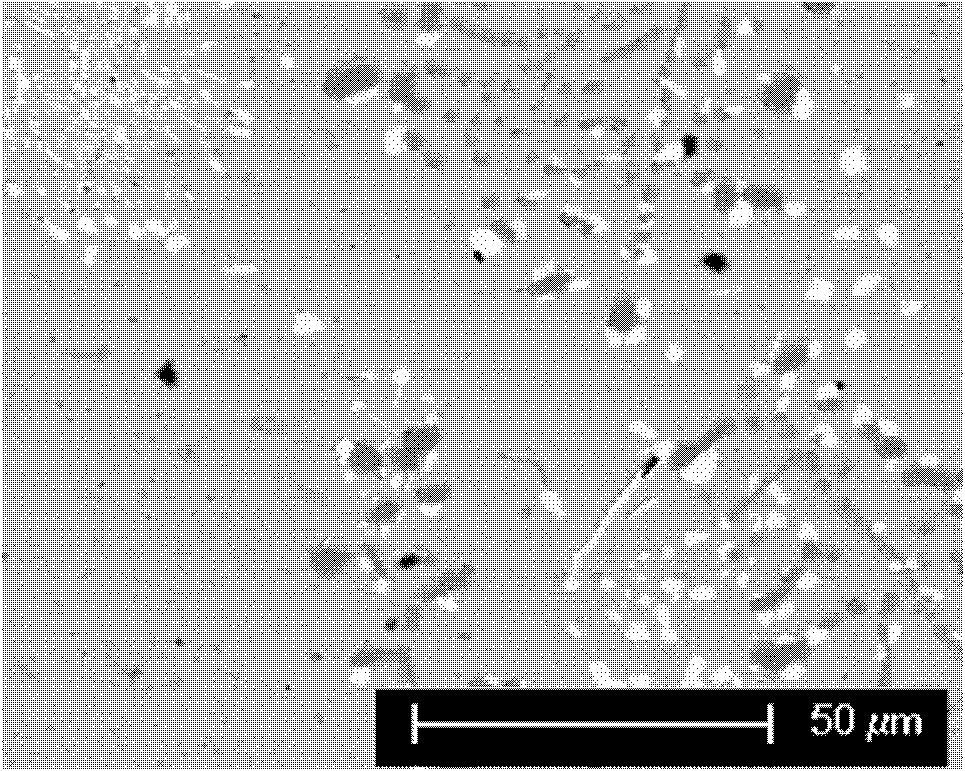

[0023] The tin, bismuth, and silver with a purity of 99.99% are heated to 1100°C in a vacuum melting furnace under the protection of argon in a mass ratio of 93:5:2, and are magnetically stirred at the same time to make the alloy composition uniform, and then water-cooled and solidified . Then the alloy is turned over and reheated to 500° C. to melt, and at the same time, it is magnetically stirred and water-cooled, so that the Sn-5%Bi-2%Ag lead-free solder is obtained by repeating this process at least four times. Its microstructure is as figure 2 As shown, the particles are Ag 3 Sn phase, white particles are Bi, the alloy has a lower melting point, higher microhardness and tensile strength.

Embodiment 3

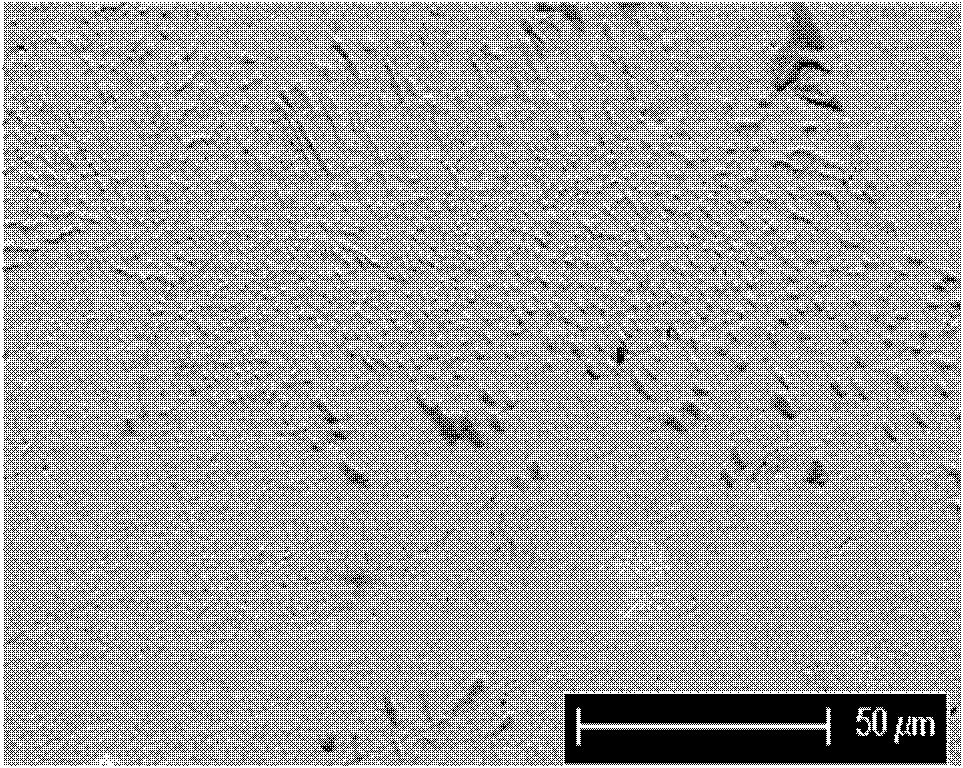

[0025] The tin, bismuth, silver, zinc, and indium with a purity of 99.99% are heated to 1100 ° C in a vacuum melting furnace under the protection of argon in a mass ratio of 95.4: 2: 0.5: 2: 0.1, and are magnetically stirred at the same time. Make the alloy composition uniform, and then freeze and solidify. The alloy is turned over and reheated to 500° C. to melt, magnetically stirred and water-cooled at the same time, thus repeated at least four times to obtain Sn-2%Bi-0.5%Ag-2%Zn-0.1%In lead-free solder. Its microstructure is as image 3 As shown, the particles are Ag 3 Sn phase and Ag-Zn phase, the white enrichment area is Bi.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com