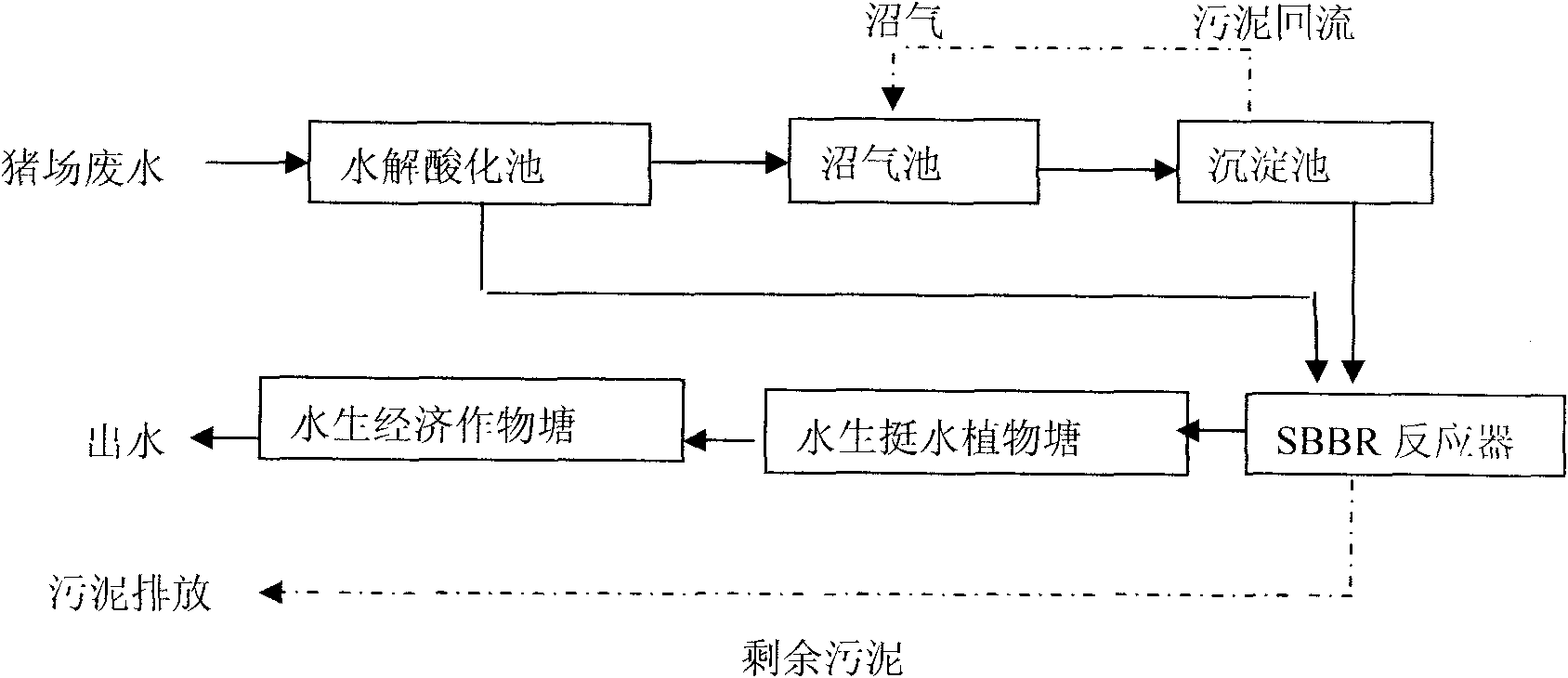

Technology for treating piggery wastewater by methane tank, biofilm reactor and artificial wetland

A biofilm reactor and artificial wetland technology, applied in the field of environmental engineering, can solve the problems of high cost, effluent water quality not meeting discharge requirements, unsatisfactory treatment effect, etc., to improve treatment capacity, improve nitrogen removal efficiency, and improve resistance Effect of Shock Load Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Pig farm wastewater with a daily treatment capacity of 150m3 / d, raw water quality: COD 5000~10000mg / L, NH4+-N 400~1500mg / L TP30~100mg / L. The raw water enters the hydrolytic acidification tank, and then enters the biogas digester. The metabolic function of heterotrophic bacteria is used to decompose the refractory organic matter into easily biodegradable small molecule organic matter, and at the same time mineralize the organic nitrogen, and degrade and remove most of the easily biodegradable organic matter. However, the anaerobic part does not remove NH4+-N, but TN increases instead. The effluent from the biogas tank is COD 500-1000mg / L, NH4+-N 400-1500mg / L, and TP 50-150mg / L; the effluent from the biogas tank flows into the SBBR reactor, and the SBBR runs Working conditions and process conditions: water inflow for 1 hour, anaerobic for 3 hours, aerobic for 7 hours, sedimentation for 0.5 hours, drainage for 0.5 hours, SBBR effluent COD 300~400mg / L, NH4+-N 40~80mg / L TP 5~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com