Preparation method of polyacrylonitrile spinning solution

A polyacrylonitrile spinning and acrylonitrile technology, which is applied in the direction of single-component synthetic polymer rayon, textiles and papermaking, fiber chemical characteristics, etc., can solve the problems of copolymer hydrophilicity decline, etc., and achieve narrow molecular weight distribution, Good hydrophilicity, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

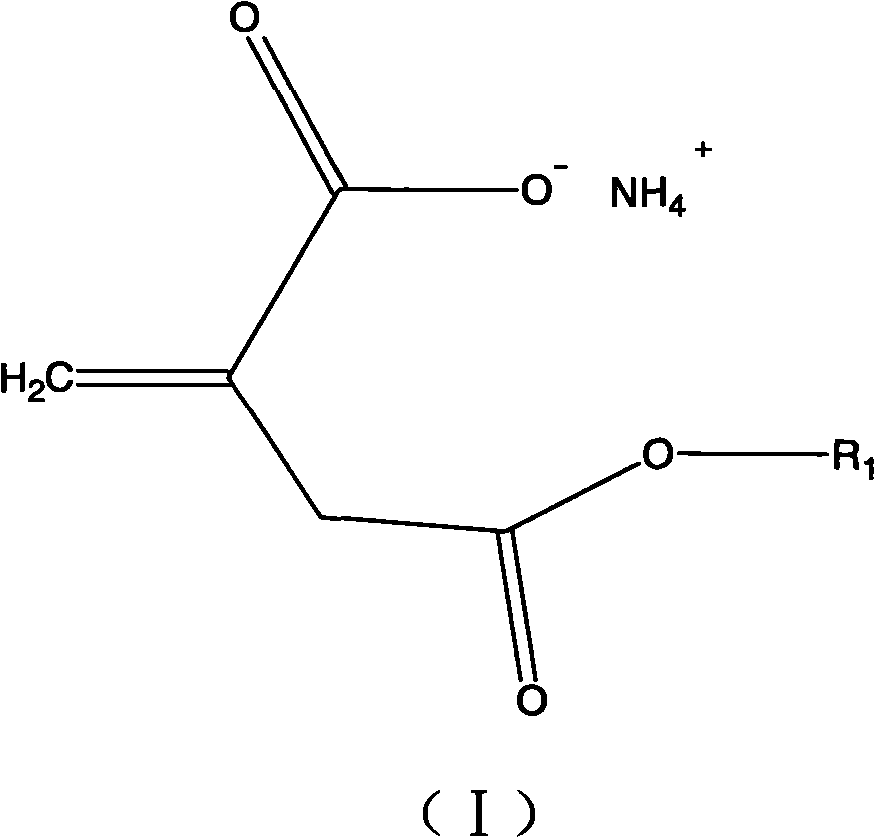

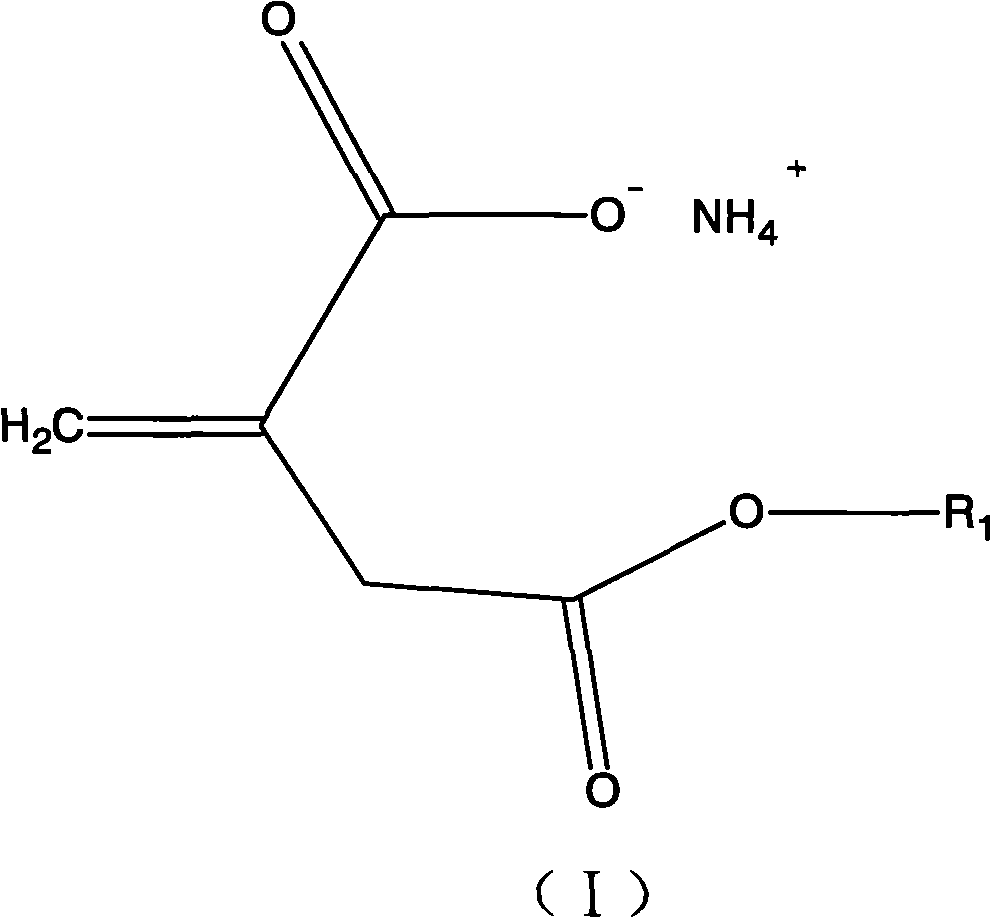

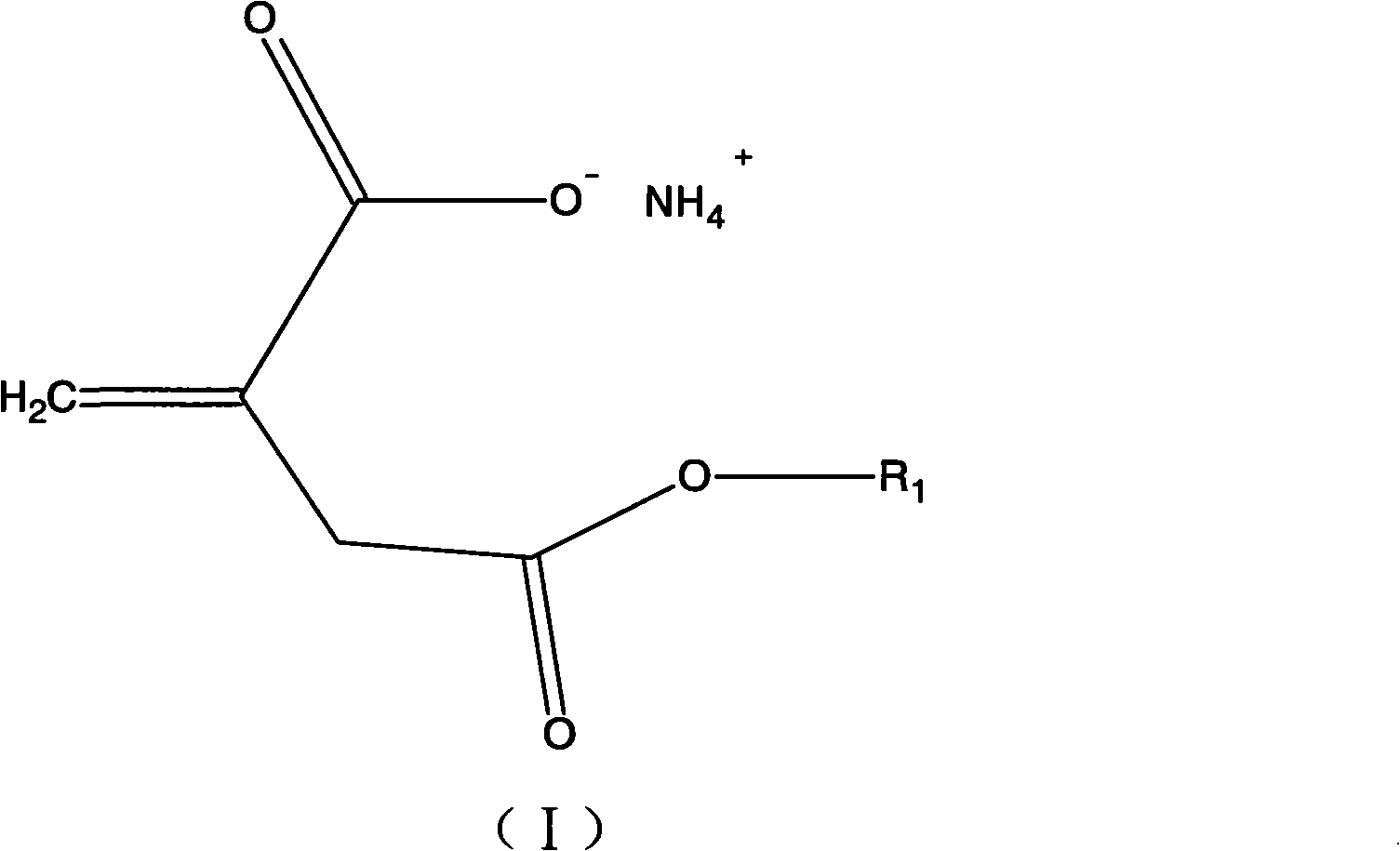

[0028] With 10kg acrylonitrile, 40kg dimethyl sulfoxide, 100g itaconate monomethyl ammonium compound (R 1 =1) Add it to a 100L reaction kettle, raise the temperature of the still and static mixer jacketed circulating water to 60°C, and add 60g of azobisisobutyronitrile after passing nitrogen through the kettle for 30 minutes. The polymerization was stopped after 12 hours, and the obtained polymer had a molecular weight of 150,000 and a molecular weight distribution of 2.5.

Embodiment 2

[0030] With 10kg acrylonitrile, 40kg dimethyl sulfoxide, 40g itaconate monopropyl ammonium compound (R 1 =3) Add it into a 100L reaction kettle, raise the temperature of the jacketed circulating water of the kettle and the static mixer to 60°C, and add 60g of azobisisobutyronitrile after passing nitrogen in the kettle for 30 minutes. After 1 hour of polymerization, the remaining 60 g of comonomer was added in 3 times with an interval of 1 hour between each time to obtain a polymer with a molecular weight of 155,000 and a molecular weight distribution of 2.5.

Embodiment 3

[0032] With 10kg acrylonitrile, 40kg dimethyl sulfoxide, 40g itaconate monomethyl ammonium compound (R 1 =1) Add it into a 100L reaction kettle, raise the temperature of the still and static mixer jacket circulating water to 50°C, and add 60g of azobisisoheptanonitrile after passing nitrogen in the kettle for 30min. After 1 hour of polymerization, the remaining 60 g of comonomer was added in 3 times with an interval of 1 hour between each time, and the reaction was stopped after 12 hours to obtain a polymer with a molecular weight of 165,000 and a molecular weight distribution of 2.3. The contact angle of the copolymer film with water is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com