Radiation type heat insulation powder paint for aluminum alloy sectional materials and preparation method thereof

A technology for aluminum alloy profiles and powder coatings, which is applied in powder coatings, reflective/signal coatings, polyester coatings, etc., can solve the problem of inability to use aluminum alloy profiles, and achieve the effects of lowering temperature, low cost and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

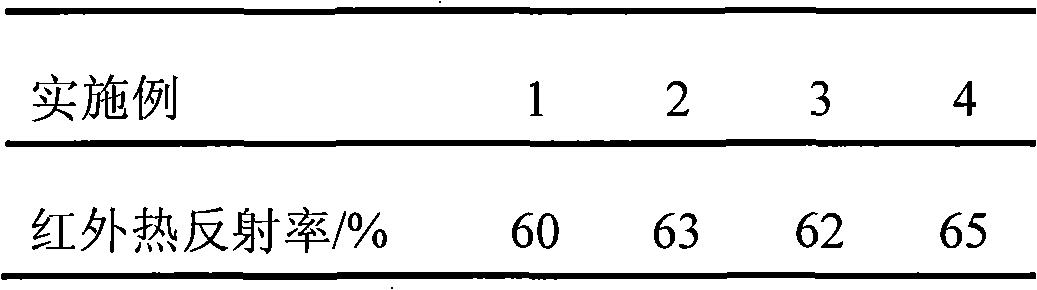

Examples

Embodiment 1

[0029] formula:

[0030] SJIV-A 100g

[0031] TGIC 10g

[0032] GLP 505 1.5g

[0033] Benzoin 0.6g

[0034] Fe 2 o 3 4 grams

[0035] al 2 o 3 6 grams

[0036] Titanium dioxide 35 grams

[0038] 1 Preparation of thermal insulation powder coating

[0039] Measure and weigh the film-forming agent, curing agent, leveling agent, degassing agent, infrared radiation material, and filler according to the formula, add them to the mixer and mix them for 15 minutes, so that all components are fully mixed evenly, and the evenly mixed materials are sent into the Twin-screw melt-mixing extruder, the temperature of the feeding section of the extruder is 110°C, and the temperature of the discharging section is 115°C. After the material is discharged, it is cooled to room temperature through cooling roller compression. Send it to the ACM series micro-milling system of Yantai Donghui Powder Equipment Co., Ltd. for high...

Embodiment 2

[0048] formula:

[0049] SJIV-A 100g

[0050] TGIC 7 grams

[0051] GLP 505 0.8 g

[0052] Benzoin 0.3g

[0053] Y 2 o 3 3 grams

[0054] CuO 4 g

[0055] Titanium dioxide 30g

[0057] 1 Preparation of thermal insulation powder coating

[0058] Measure and weigh the film-forming agent, curing agent, leveling agent, degassing agent, infrared radiation material, and filler according to the formula, add them to the mixer and mix for 15 minutes to make each component fully mixed evenly, and send the evenly mixed materials into the double Screw melt mixing extruder, the temperature of the feeding section of the extruder is 115°C, and the temperature of the discharging section is 125°C. After discharging, it is cooled to room temperature through cooling roller compression. Send it to the ACM series micro-milling system of Yantai Donghui Powder Equipment Co., Ltd. for high-speed crushing, air classification, cyclone separation, siev...

Embodiment 3

[0062] formula:

[0063] SJIV-A 100g

[0064] TGIC 9 grams

[0065]GLP 505 1.2g

[0066] Benzoin 0.5g

[0067] SiO 2 8 grams

[0068] NiO 2 g

[0069] Titanium dioxide 35 grams

[0071] Measure and weigh the film-forming agent, curing agent, leveling agent, degassing agent, infrared radiation material, and filler according to the formula, add them to the mixer and mix for 15 minutes to make each component fully mixed evenly, and send the evenly mixed materials into the double Screw melt mixing extruder, the temperature of the feeding section of the extruder is 105°C, and the temperature of the discharging section is 110°C. After discharging, it is cooled to room temperature through cooling roller compression. Send it to the ACM series micro-milling system of Yantai Donghui Powder Equipment Co., Ltd. for high-speed crushing, air classification, cyclone separation, sieving, and ultrafine powder separation and collection. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com