Preparation method of homodisperse carbon nano tube enhanced aluminium base composite material

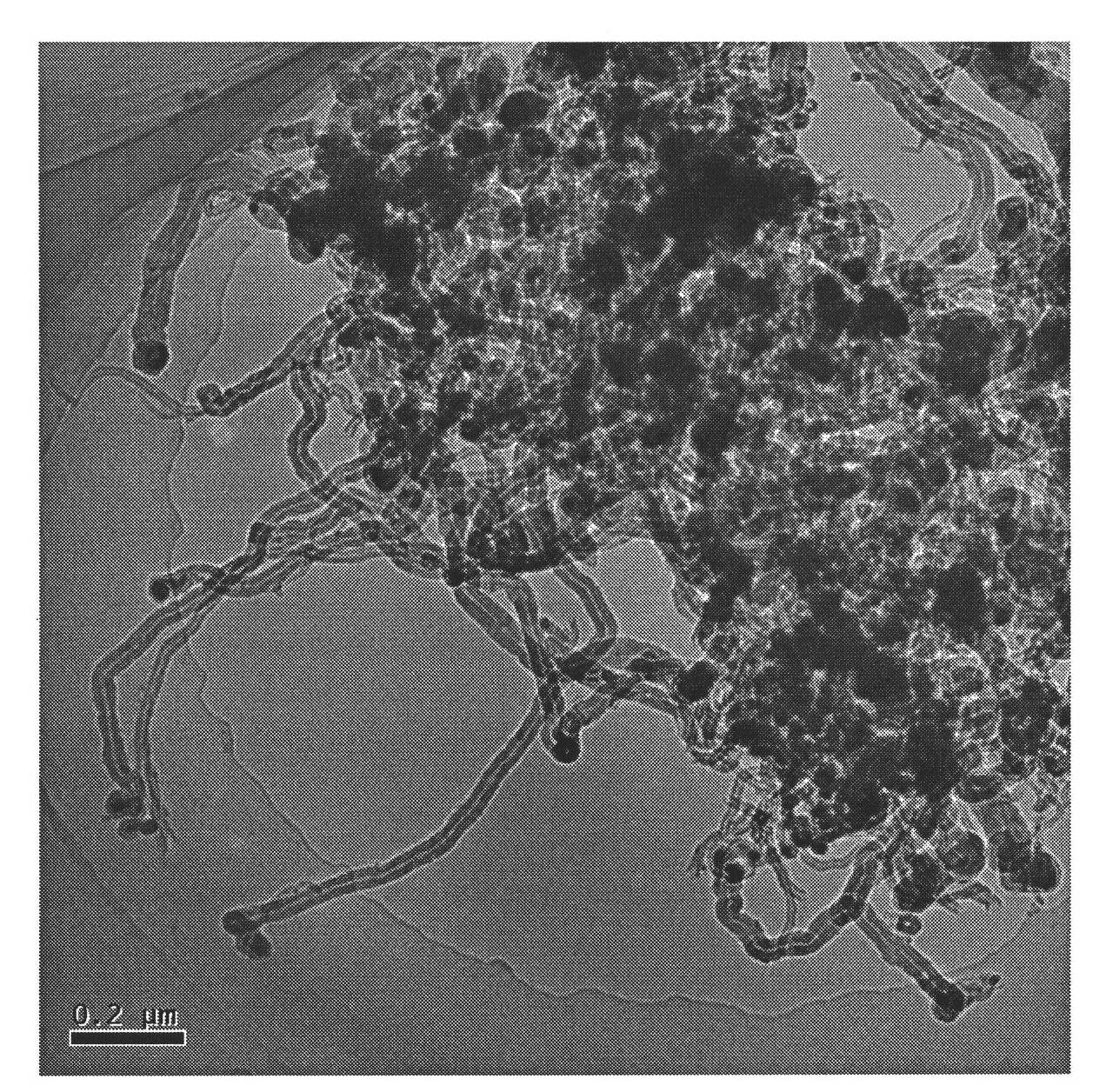

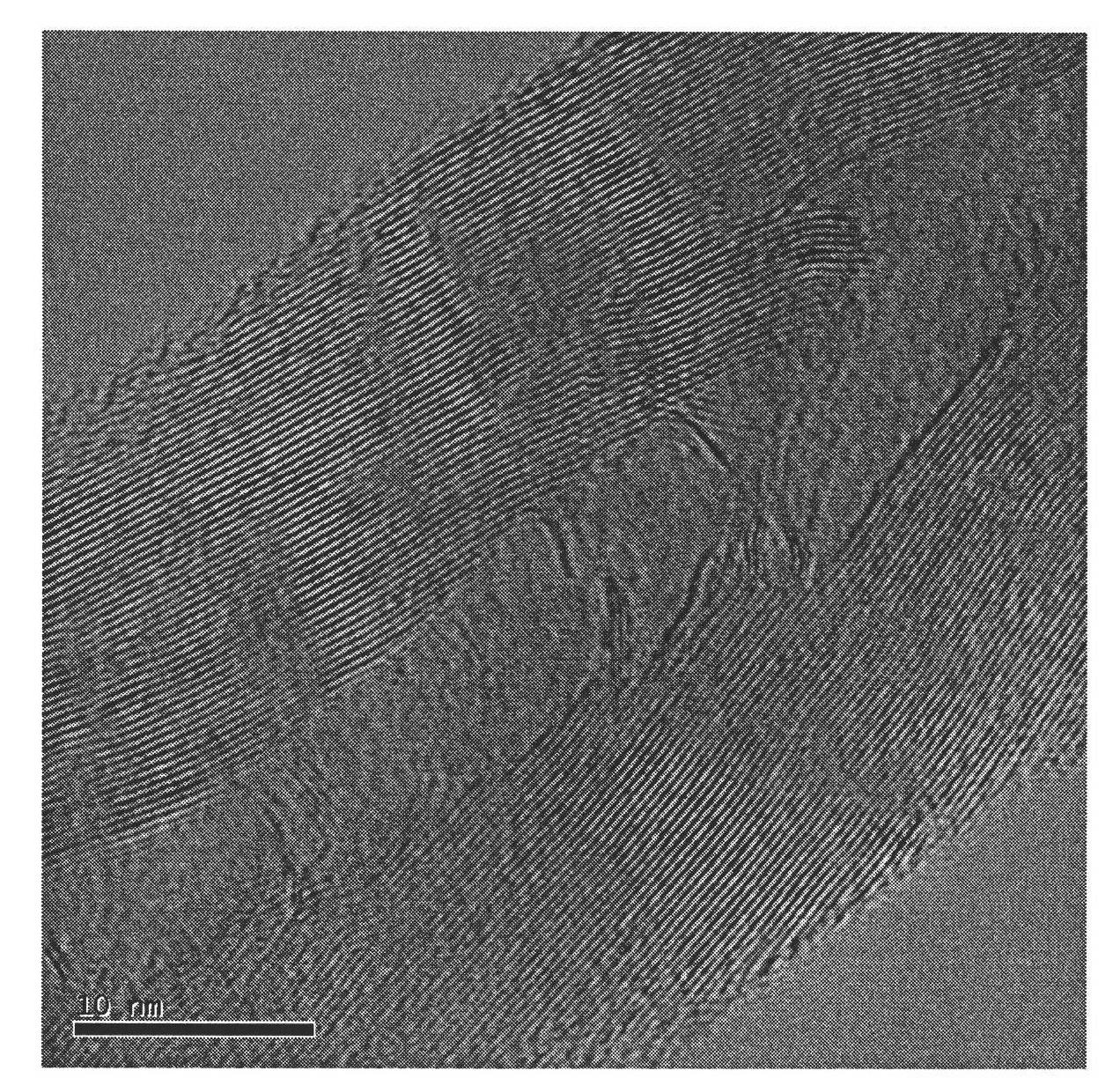

An aluminum-based composite material and uniform dispersion technology, which is applied in the field of preparation of uniformly dispersed carbon nanotube-reinforced aluminum-based composite materials, can solve the difficult problem of carbon nanotube agglomeration, poor process stability and reproducibility, and difficult batch production Production and other problems, to achieve the effect of complete structure, good combination and good crystallization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

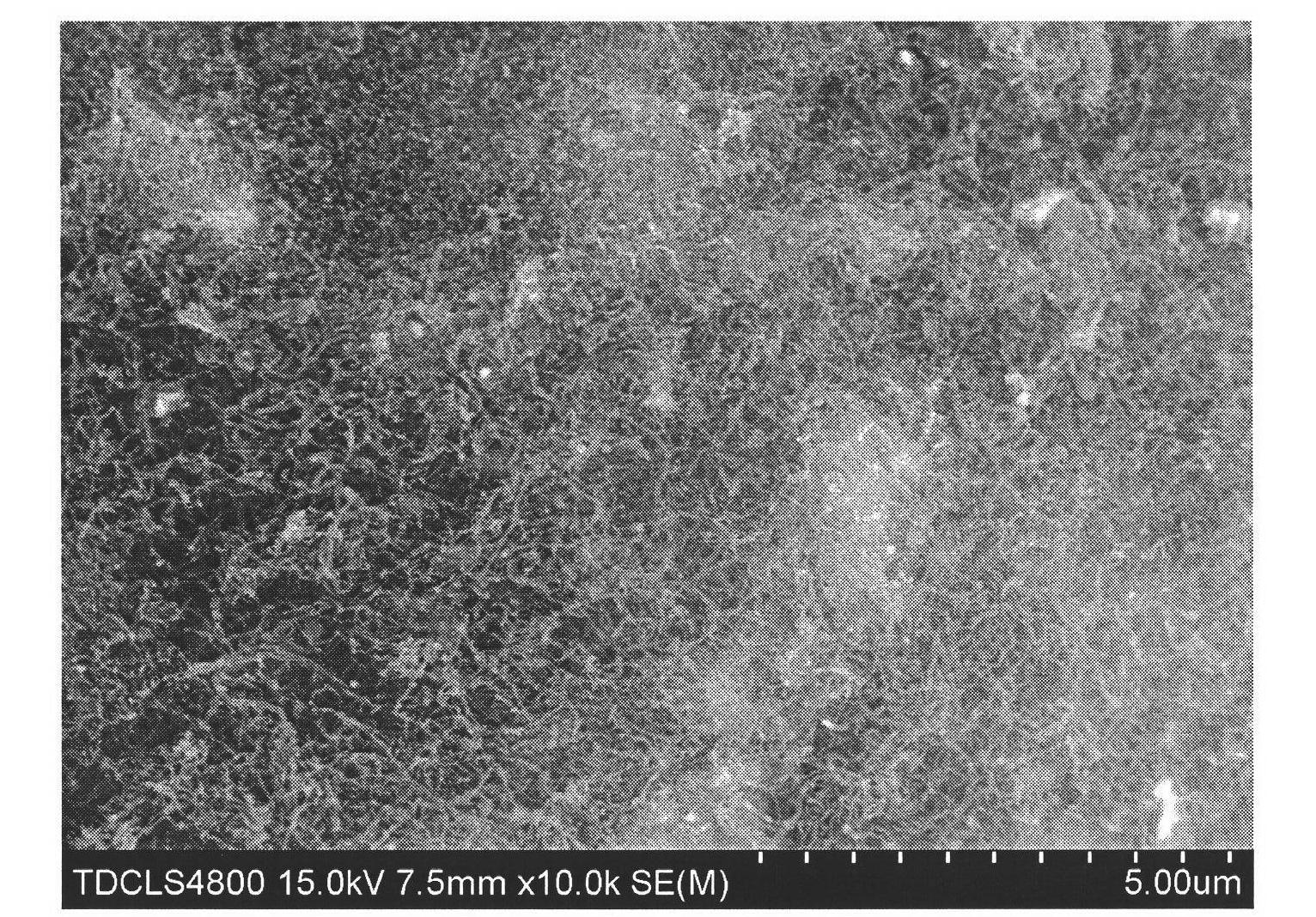

Embodiment 1

[0028] Mix 0.424g of nickel acetate tetrahydrate with 19.9g of aluminum powder, add to 120ml of absolute ethanol, evaporate to dryness with magnetic stirring at 60°C, place at room temperature for 24 hours and dry to obtain the precursor powder. Take a certain amount of powder and place it in the constant temperature zone of the tube furnace, raise the temperature to 250°C under the protection of argon, turn off the argon, pass in hydrogen at a flow rate of 200mL / min, keep it at 250°C for 1 hour, then raise the temperature to 450°C and keep it for 2 hours. hour, turn off the hydrogen, feed argon and continue to heat up to 600°C, then feed a mixed gas of methane and argon (methane flow rate 60mL / min, argon flow rate 420mL / min) and react for 15 minutes. Cool to room temperature with the furnace under gas protection to obtain carbon nanotube and aluminum composite powder, the content of carbon nanotube in the composite powder is 1.3wt.%. The composite powder was pressed into a bl...

Embodiment 2

[0030] Mix 0.53g of nickel acetate tetrahydrate with 2.38g of aluminum powder, add to 120ml of absolute ethanol, evaporate to dryness with magnetic stirring at 70°C, place at room temperature for 24 hours and dry to obtain the precursor powder. Take a certain amount of powder and place it in the constant temperature zone of the tube furnace, raise the temperature to 250°C under the protection of argon, turn off the argon, feed hydrogen at a flow rate of 150mL / min, keep it at 250°C for 1 hour, then raise the temperature to 450°C and keep it for 1 hour. Hours, turn off the hydrogen, feed argon to continue to heat up to 600 ° C, then feed a mixed gas of methane and argon (methane flow rate 60mL / min, argon flow rate 420mL / min) after 1 hour of reaction, close the mixed gas, Cool down to room temperature with the furnace under gas protection to obtain carbon nanotube and aluminum composite powder. The carbon nanotube content in the composite powder is 9.8wt.%.

Embodiment 3

[0032] The specific method and steps are the same as in Example 2, except that the different conditions are: the temperature of vapor phase deposition and growth of carbon nanotubes is 450°C, and finally a carbon nanotube and aluminum composite powder with a carbon nanotube content of 10.7wt.% is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com