Method for preparing high-orientation PZT piezoelectric thin film

A piezoelectric film and high orientation technology, which is applied in the field of preparation of high orientation PZT piezoelectric film, can solve the problems of low perovskite phase ratio and difficulty in forming crystallization nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

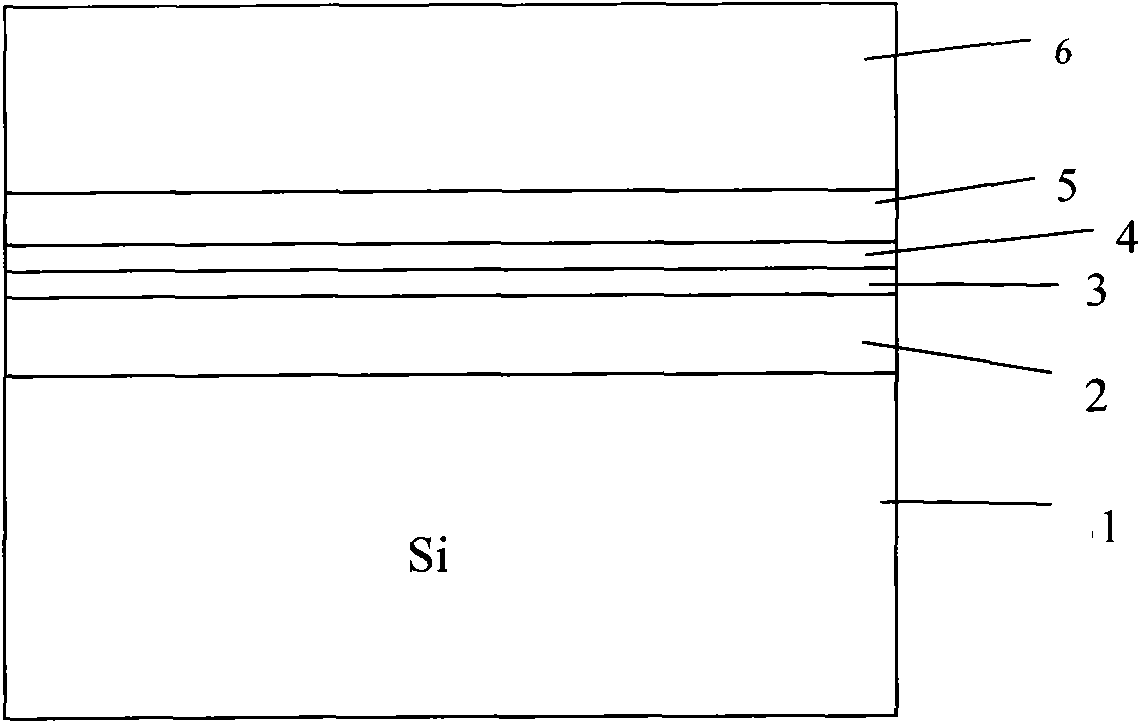

[0019] The Si wafer is cleaned by the conventional cleaning method of the Si wafer in the IC industry, and SiO is grown on the silicon wafer by thermal growth method. 2 The thickness of the layer is 1 μm, and then a Ti layer of 10 nm is deposited by sputtering or CVD, and a Pt layer of 100 nm is deposited by sputtering or CVD, and the growth of the PZT layer adopts a two-step method. That is, MOCVD or sputtering is used to slowly grow a PT seed layer (seed layer) of 50 nm, and then increase the sputtering rate to grow or spin coat a PZT layer.

[0020] After the PT grows and before the PZT, the PT layer is subjected to a rapid annealing process (RTP) once. During the growth of the PZT layer, a rapid annealing process (RTP) is performed every 300nm

Embodiment 2

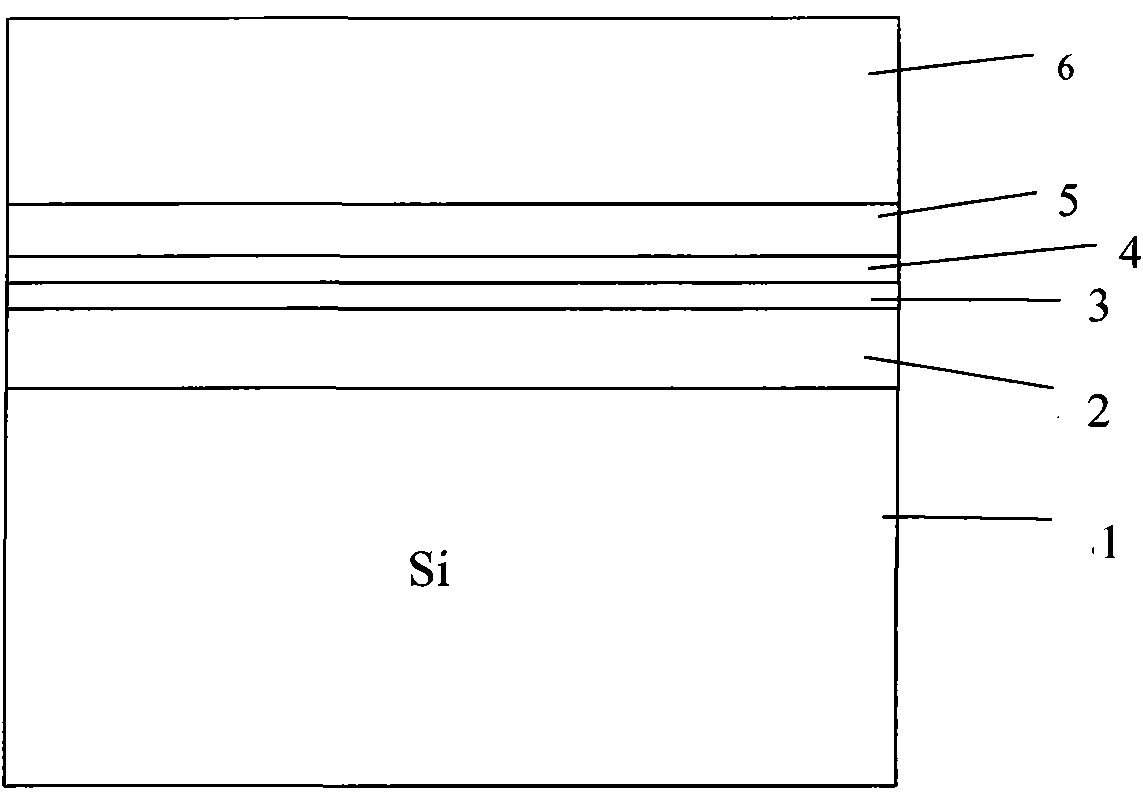

[0022] The Si wafer is cleaned by the conventional cleaning method of the Si wafer in the IC industry, and SiO is grown on the silicon wafer by thermal growth method. 2 The thickness of the layer is 0.5um, and then sputtering method or CVD method is used to deposit TiO, Ti layers are 75nm and 100nm respectively, and then sputtering method or CVD method is used to deposit Pt layer 100nm, and the growth of PZT layer adopts two-step method. That is, the sputtering method is used to slowly grow the PT seed layer (seed layer) 50nm, and then increase the sputtering rate to grow or spin-coat the PZT layer.

[0023] After the PT grows and before the PZT, the PT layer is subjected to a rapid annealing process (RTP) once. During the growth of the PZT layer, a rapid annealing process (RTP) is performed every 300nm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com