Acrylic acid modified waterproof mortar

A waterproof mortar, acrylic technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of no aging resistance, and achieve excellent waterproof and impermeability, excellent folding resistance, good adhesion The effect of bonding strength and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

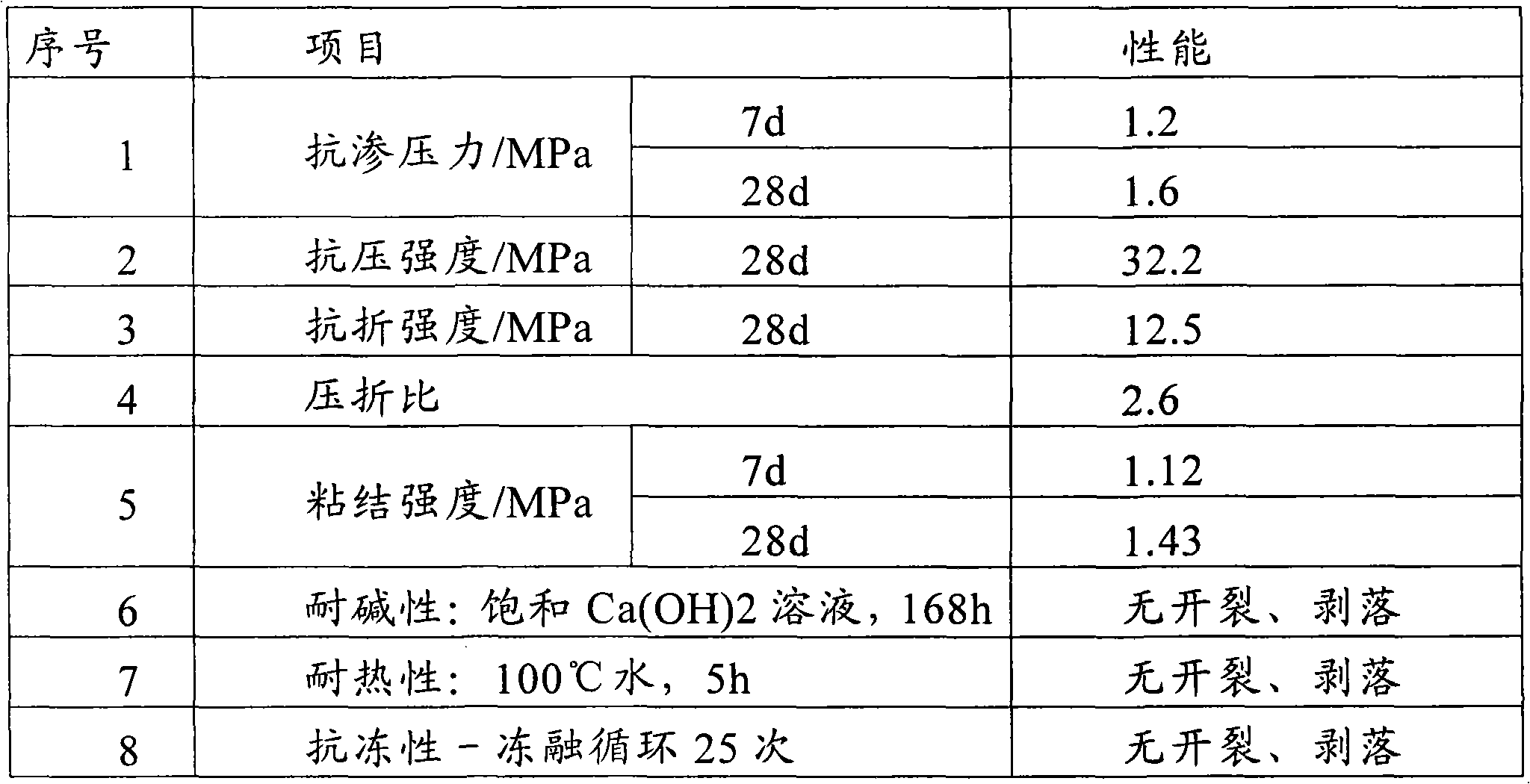

[0028] The raw material composition and mass parts of a kind of acrylic acid modified waterproof mortar are as shown in table 1:

[0029] Table 1 raw material composition and mass parts thereof

[0030] raw material name

model

weight

425

42

Quartz sand

30-50 mesh

20

Stone yellow sand

50-100 mesh

20

Class II

15

heavy calcium

200 mesh

5

redispersible rubber powder

695P

3.5

HK8000

0.02

Hydrophobic agent

69051

0.2

Modified bentonite

-

0.2

P210

0.3

[0031] Superplasticizer

CPC-1

0.15

Polypropylene fibers

PP6

0.2

[0032] The preparation method of the above-mentioned waterproof mortar is as follows: according to the ratio of raw materials, various raw materials are added into the mixing / stirring tank in se...

Embodiment 2

[0038] A kind of raw material composition and mass parts of acrylic acid modified waterproof mortar are as shown in table 3:

[0039] Table 3 raw material composition and mass parts thereof

[0040] raw material name

model

weight

425

45

Quartz sand

40-70 mesh

18

[0041] raw material name

model

weight

Quartz sand

70-140 mesh

20

Class II

6

heavy calcium

200 mesh

15

redispersible rubber powder

695P

3

MC7000PF

0.04

Hydrophobic agent

P750

0.1

Modified bentonite

-

0.2

P210

0.25

F10

0.2

Polypropylene fibers

PP6

0.2

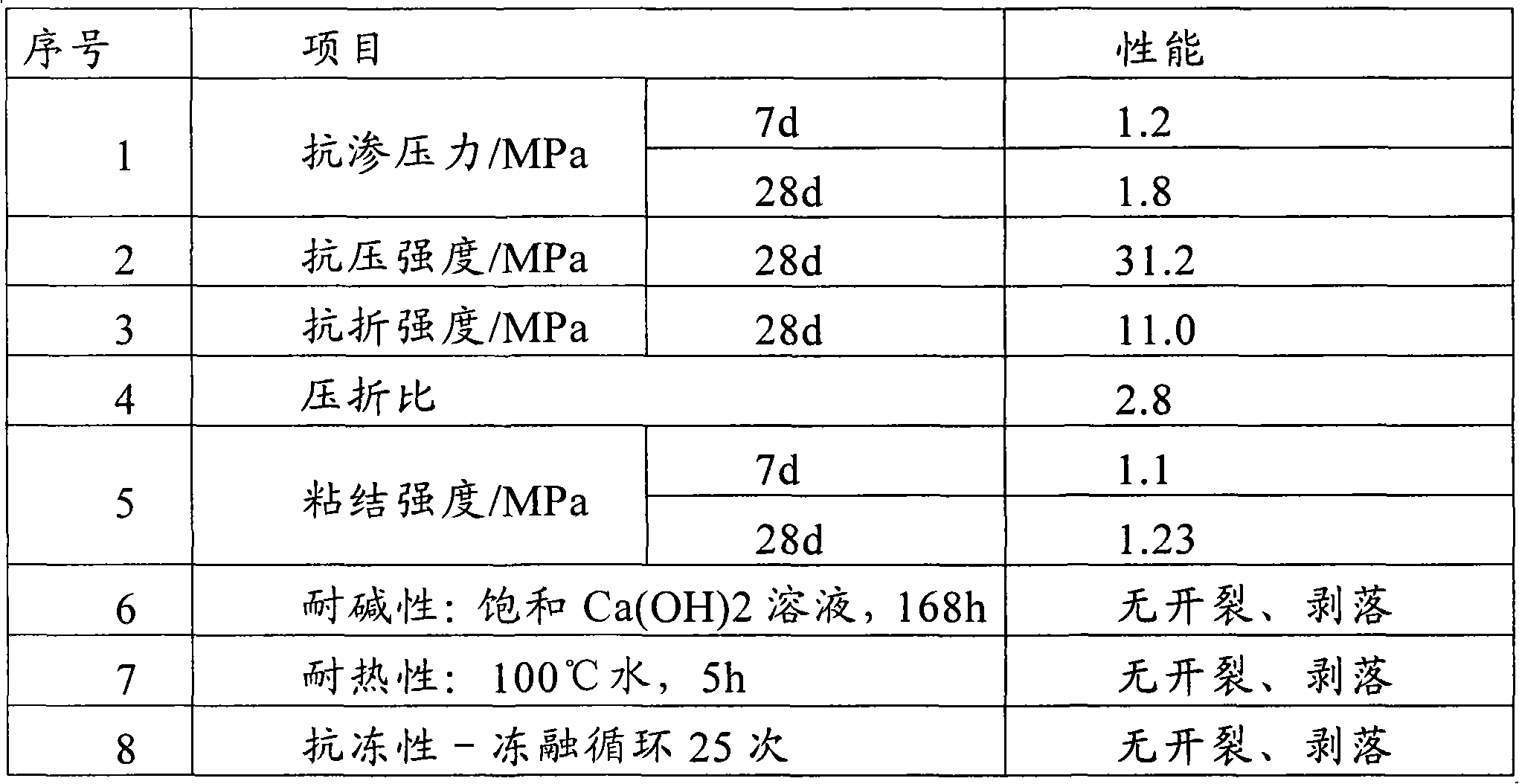

[0042] The above-mentioned waterproof mortar preparation method and application method are implemented in the same way 1, and its specific performance indicators ...

Embodiment 3

[0047] The raw material composition and mass parts of a kind of acrylic acid modified waterproof mortar are as shown in table 5:

[0048] Table 5 raw material composition and mass parts thereof

[0049] raw material name

model

weight

425

50

Quartz sand

40-70 mesh

20

Quartz sand

50-100 mesh

15

Class II

5

heavy calcium

200 mesh

7

redispersible rubber powder

695P

2.5

MC7000PF

0.05

Hydrophobic agent

69051

0.2

Modified bentonite

-

0.2

RE2971

0.2

F10

0.3

Polypropylene fibers

PP6

0.1

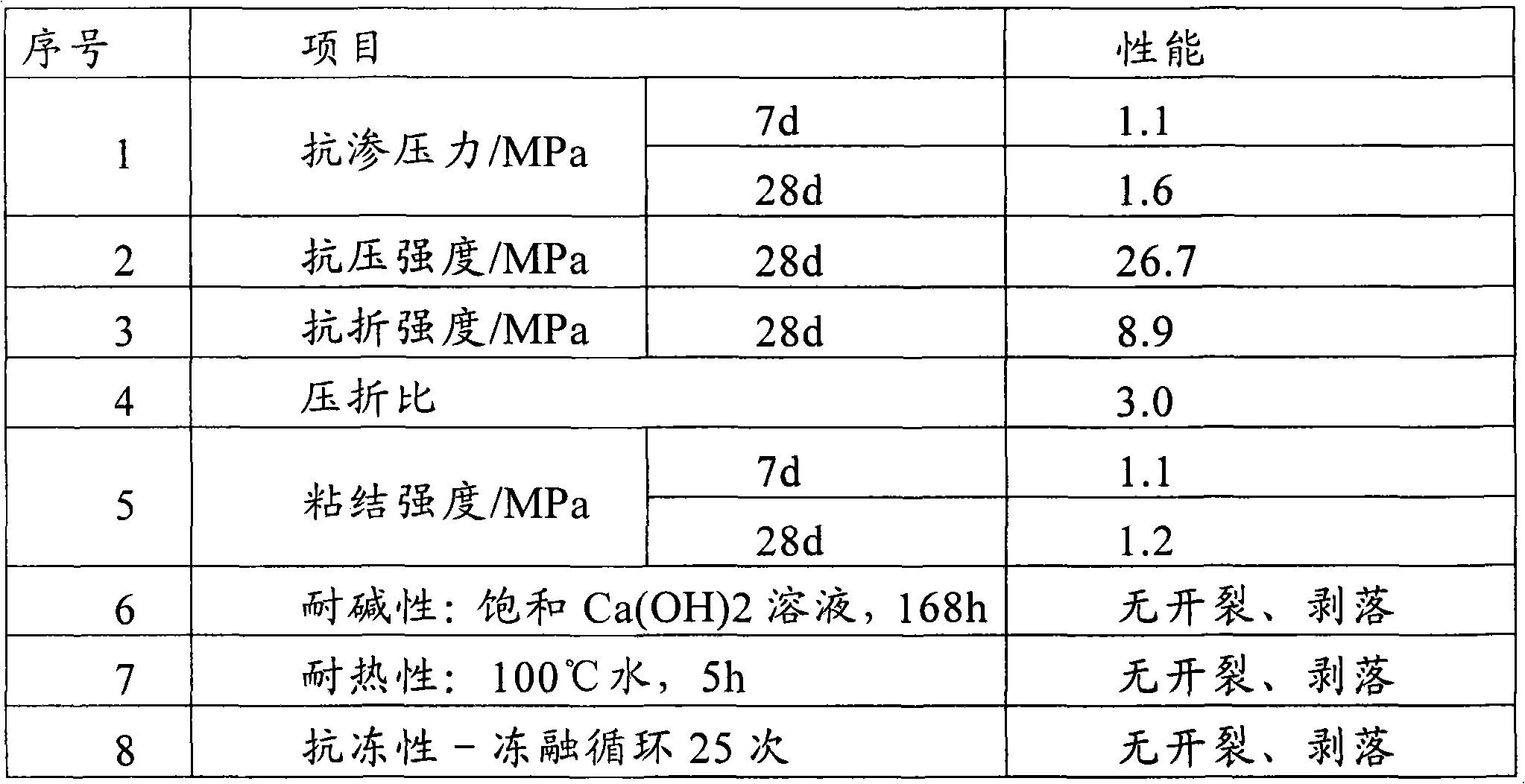

[0050] Above-mentioned waterproof mortar preparation method and using method are the same as embodiment 1, and its concrete performance index is as shown in following table 6:

[0051] Table 6 Waterproof Mortar Performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com