Preparation method of polymer film with periodic nano-structure and template used by same

A polymer film and nanostructure technology, applied in the field of polymer film preparation, can solve the problems of high cost, time-consuming, low repeatability, etc., and achieve the effects of low cost, major economic benefits, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare the template:

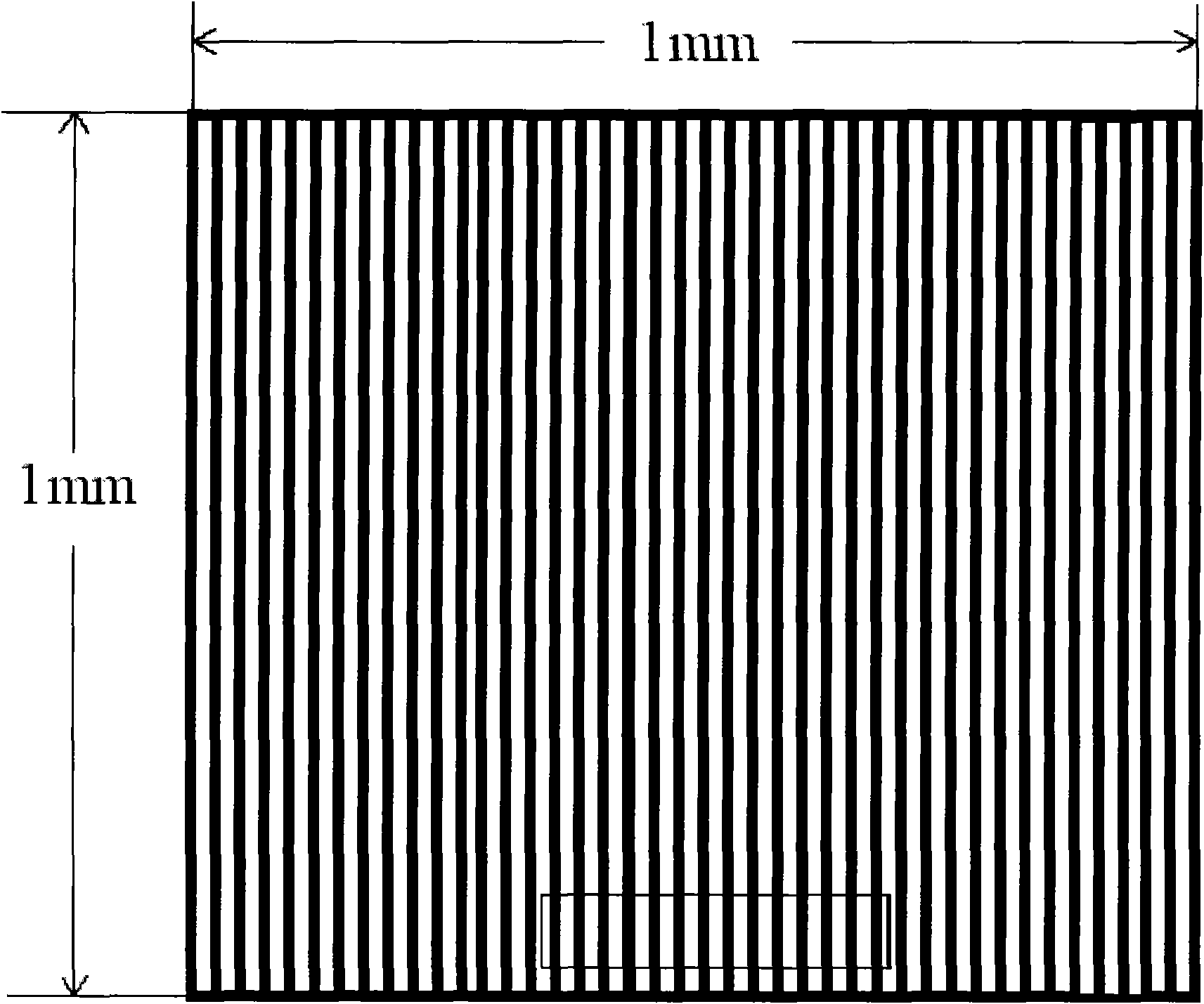

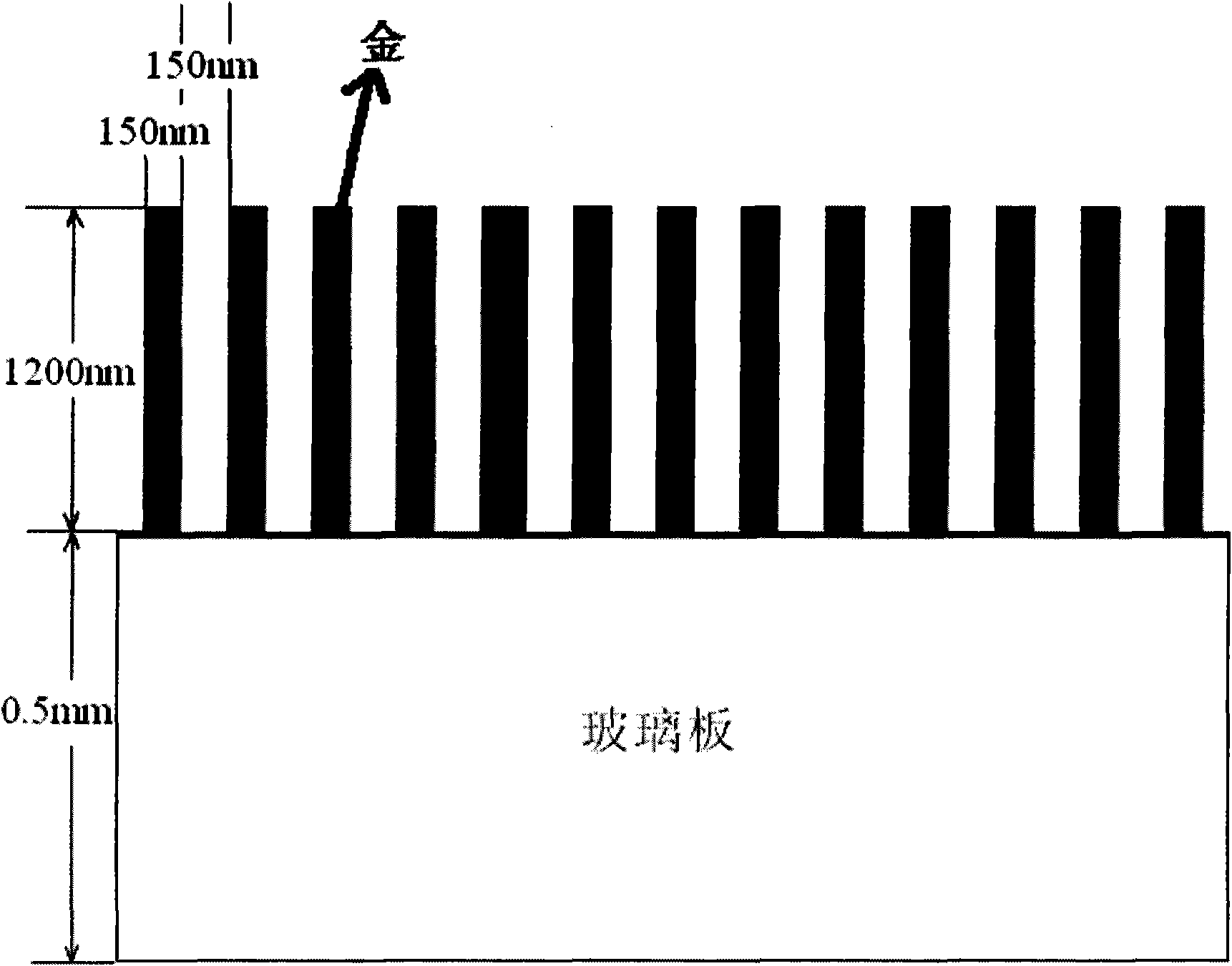

[0043] 1. Deposit mist gold onto a 1mm×1mm glass plate by vapor deposition, so that the thickness of the metal phase is 1200nm; the height of the glass plate is 0.5mm;

[0044] 2. Use the soft X-ray of the synchronous light source to etch the metallography from the angle perpendicular to the glass plate. The etching is controlled by a program. The first ray is emitted to etch away the gold bars of 150×1200nm, the ray source moves 150nm, and the second ray is emitted. By analogy, a template with a stripe width of 150nm and a stripe spacing of 150nm is finally obtained. Soft X-ray of Synchrotron Light Source Provided by Synchrotron Light Source of University of Science and Technology of China.

Embodiment 2

[0046] Select a 1mm×1mm silicon wafer, and use the soft X-ray of the synchronous light source to etch the metallographic phase from the angle perpendicular to the glass plate. The etching is controlled by a program. The first ray is emitted to etch away a 20×1200nm silicon wafer, the ray source moves 20nm, and the second ray is emitted. By analogy, a template with a stripe width of 20nm and a stripe spacing of 20nm is finally obtained. Soft X-ray of Synchrotron Light Source Provided by Synchrotron Light Source of University of Science and Technology of China.

[0047] The templates used in the following implementations are all prepared by the method of Example 1.

Embodiment 3

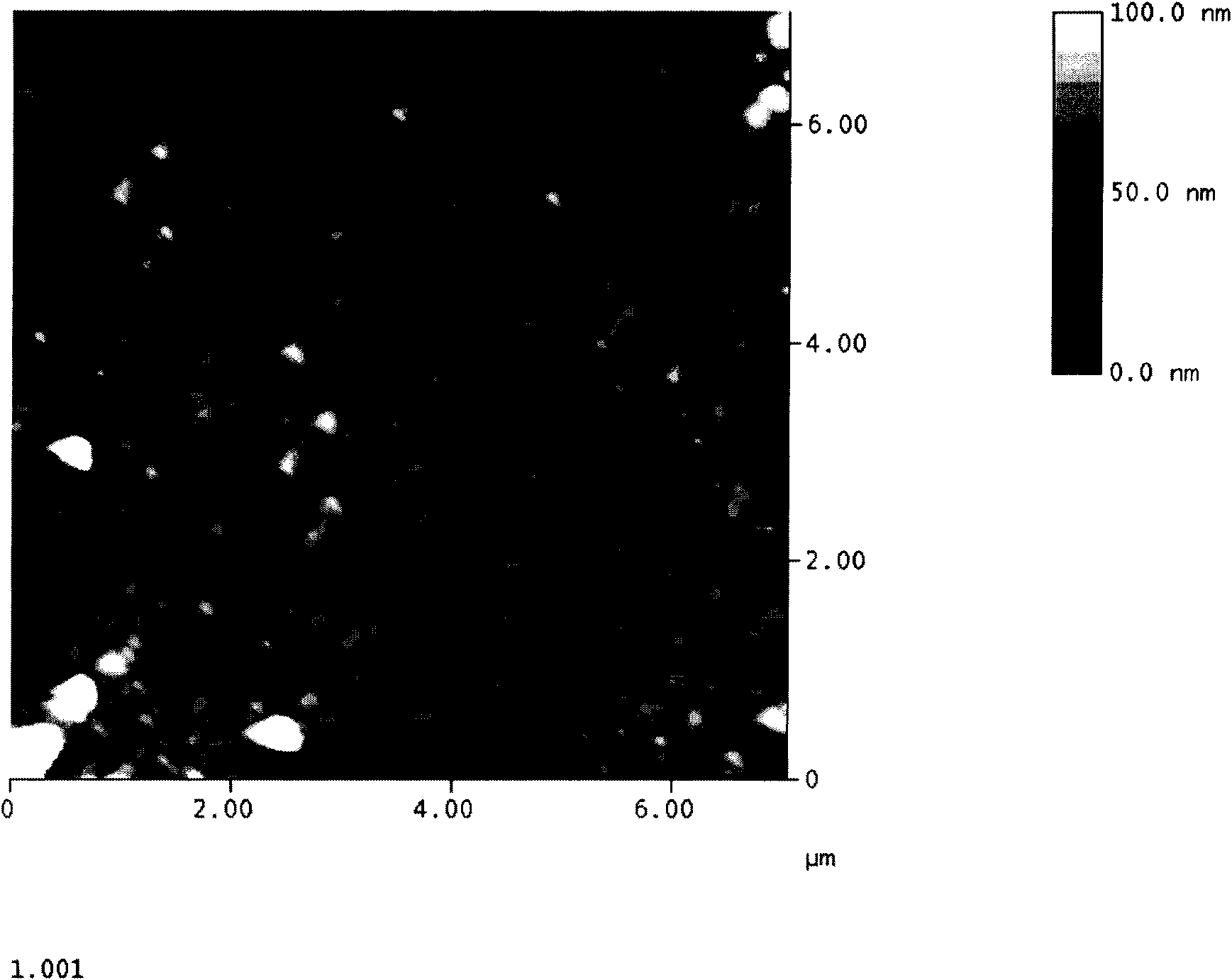

[0048] Example 3 Polyethersulfone (PES) polymer membrane (membrane 1) with periodic nanostructure

[0049] Weigh 1 gram of polyethersulfone (weight-average molecular weight: 800,000) (PES) powder with an electronic balance, with a particle size of 0.2 mm. Put the weighed powder into a 150 ml Erlenmeyer flask, add N-methylpyrrolidone (NMP) until the total weight of the solution is 100 grams, heat and dissolve the solution in an ordinary oven at 60 degrees Celsius for 3 days, and prepare the casting solution (The concentration of the casting liquid is 1%). After the obtained casting liquid was left to stand for defoaming, 1 mL of the casting liquid was sucked with a pipette gun and added dropwise on the silicon wafer template. Spin coating at 100 rpm on a glue homogenizer for 600 seconds to form a film. The spin-coated film (together with the silicon wafer template) is placed in a common oven at 60 degrees Celsius and dried to a constant weight to obtain a dry polymer film (to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Stripe width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com