Double hydraulic heating straw compression molding process and equipment

A technology of compression molding and thermoforming, which is applied in lighting and heating equipment, combustion equipment, block/powder fuel preparation, etc. It can solve the problems of high power consumption, non-adjustable pressure, and high output of a single machine to optimize the energy consumption structure. , avoid aldehyde pollution, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

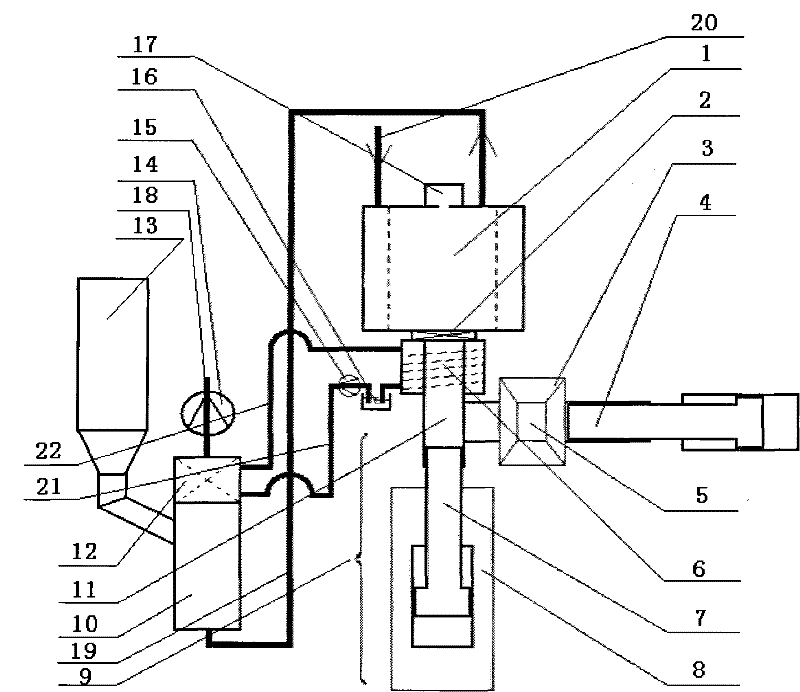

[0047] The straw raw material compressed by the double hydraulic heating straw compression molding machine provided by the present invention is the straw produced in Liaoyang area, Liaoning Province, and the application base element analysis results of the straw are: Car=41.01, Har=4.89, Oar=32.61, Nar=1.88, Sar= 0.21, Mar=6.21, Aar=13.19. The low-level calorific value of the application base is 15.513MJ / Kg. The bulk density is 103Kg / m 3 .

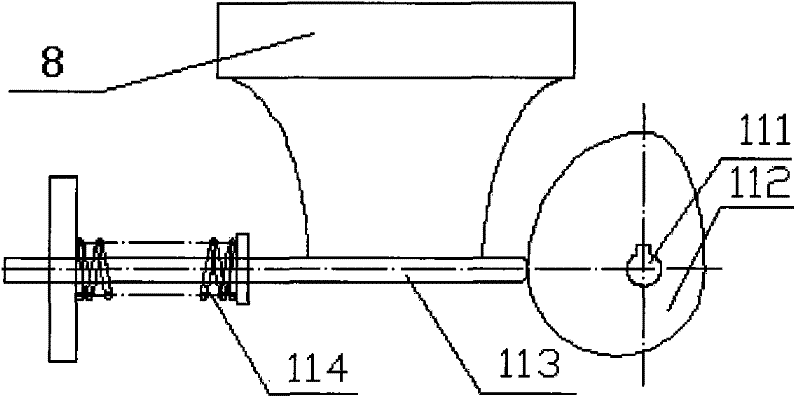

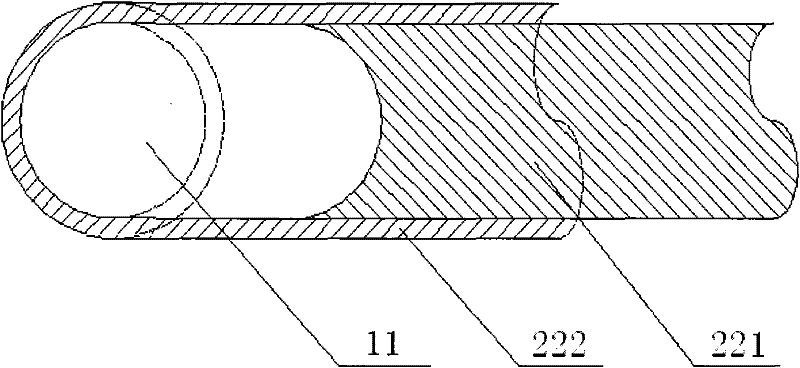

[0048] The straw raw material is stored in the hopper 3, relies on gravity, passes through the feeding port 5, and falls into the low-pressure hydraulic mechanism. The end of the piston of the low-pressure hydraulic mechanism forms a semi-cylindrical notch, and cooperates with the preforming section of the high-pressure hydraulic mechanism to compress the straw raw material into a cylindrical preforming raw material.

[0049] Straw raw materials should be compressed into shaped granules, and the ratio of the apparent density of shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com