GaN-based LED having nanometer structure inserted layer

A nanostructure and intercalation technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as thermal effects, P-type damage, and difficulty in making ohmic contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

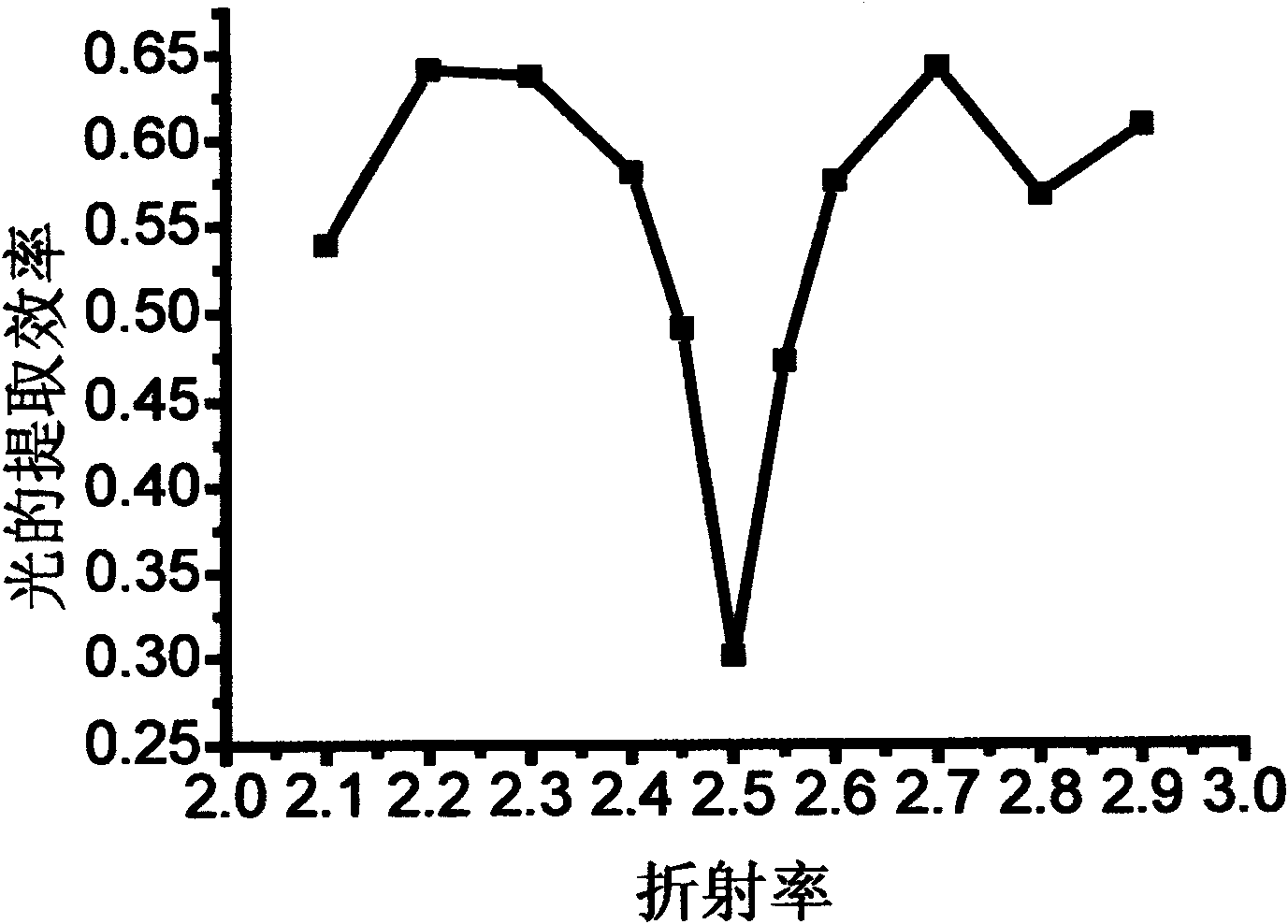

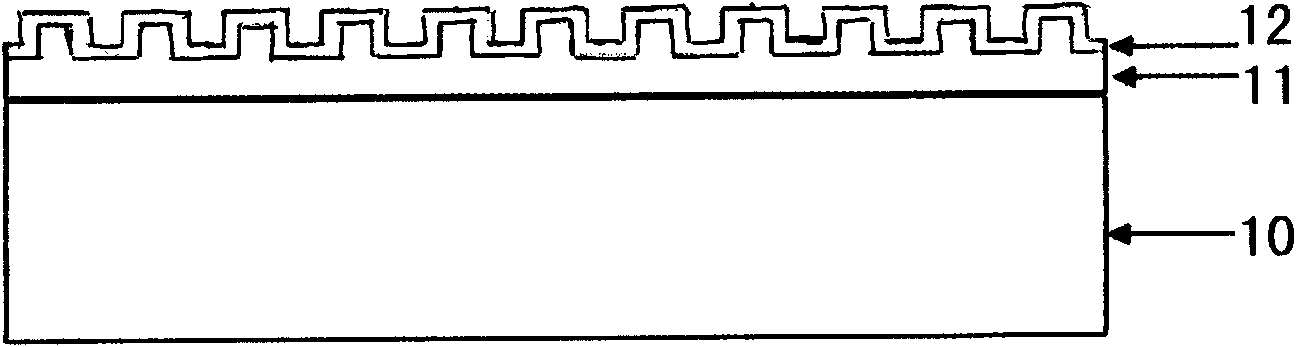

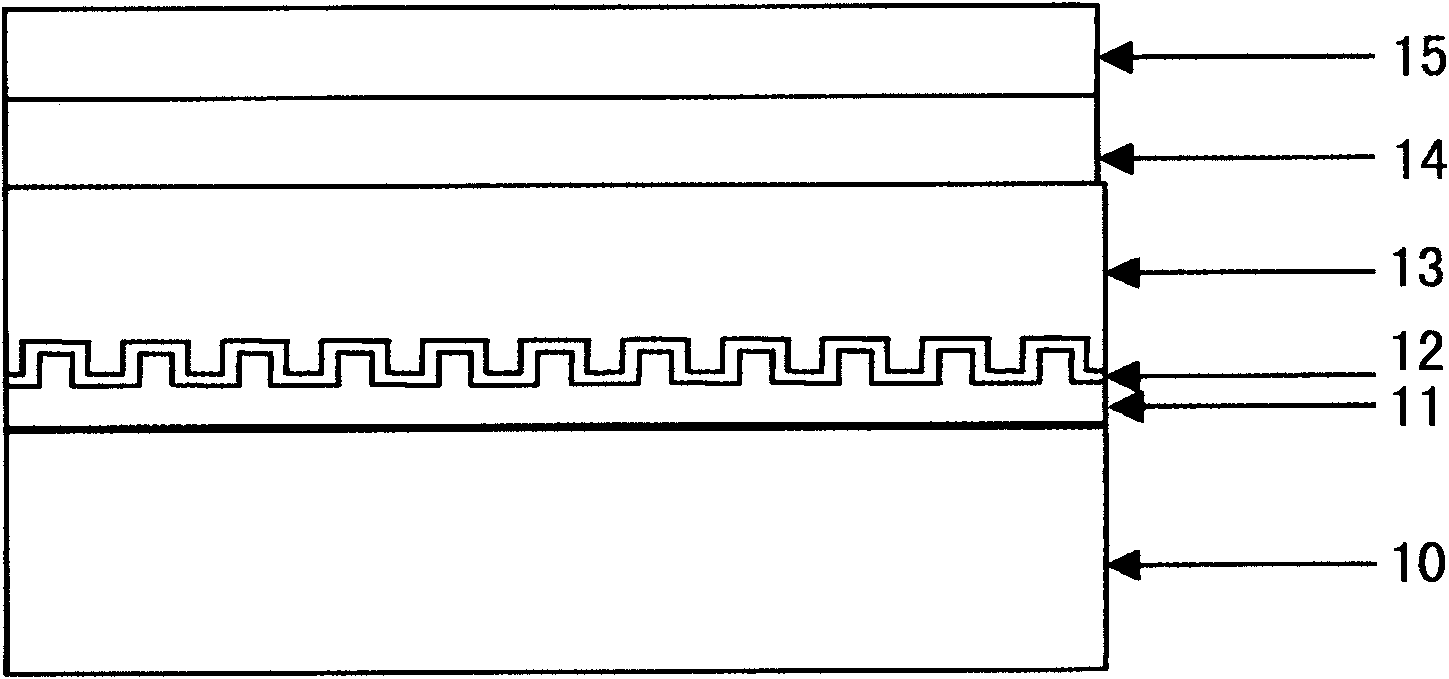

[0027] The present invention provides a GaN-based LED with a nanostructure insertion layer, comprising:

[0028] A substrate 10, the substrate 10 is made of silicon, sapphire, gallium nitride, gallium arsenide or silicon carbide;

[0029] A nanostructure template 11, the nanostructure template 11 is epitaxially grown on the substrate 10, the surface of the nanostructure template 11 is in a concave-convex shape, and the nanostructure template 11 on the concave-convex surface is obtained by electron beam exposure, holographic lithography, and two The porous alumina structure formed by step oxidation, the self-organized structure formed by metal under annealing conditions or the structure formed by silica nanoparticles is used as a mask to etch by dry etching method, or directly etched by focused ion beam wherein the surface of the nanostructure template 11 is a columnar structure, and the shape is a cylinder, a hexagonal prism, a square prism, a rhombus prism, a cubic prism, a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com