Resistor-type nonvolatile storage device and manufacturing method thereof

A non-volatile storage, resistive technology, applied in static memory, digital memory information, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

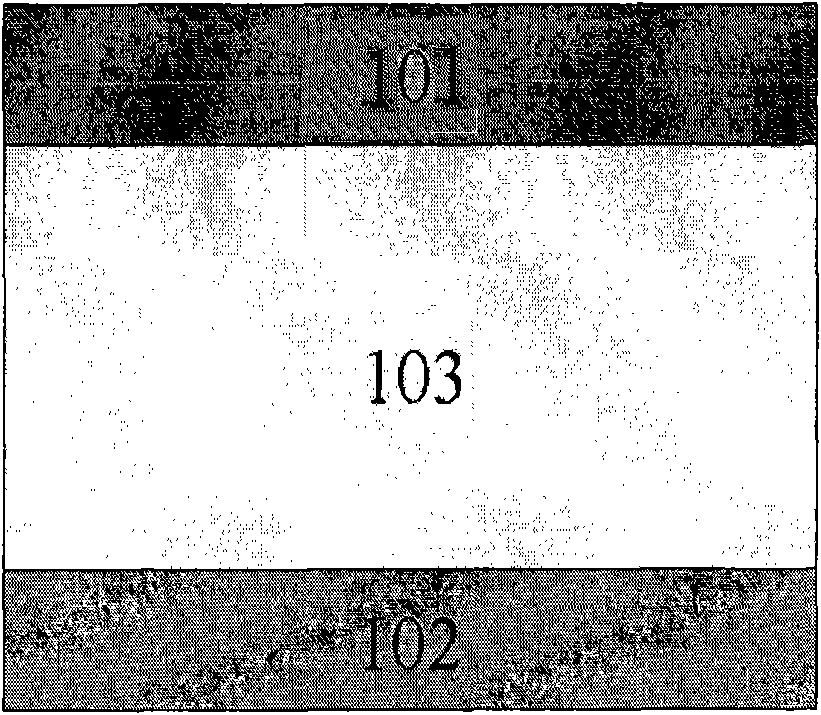

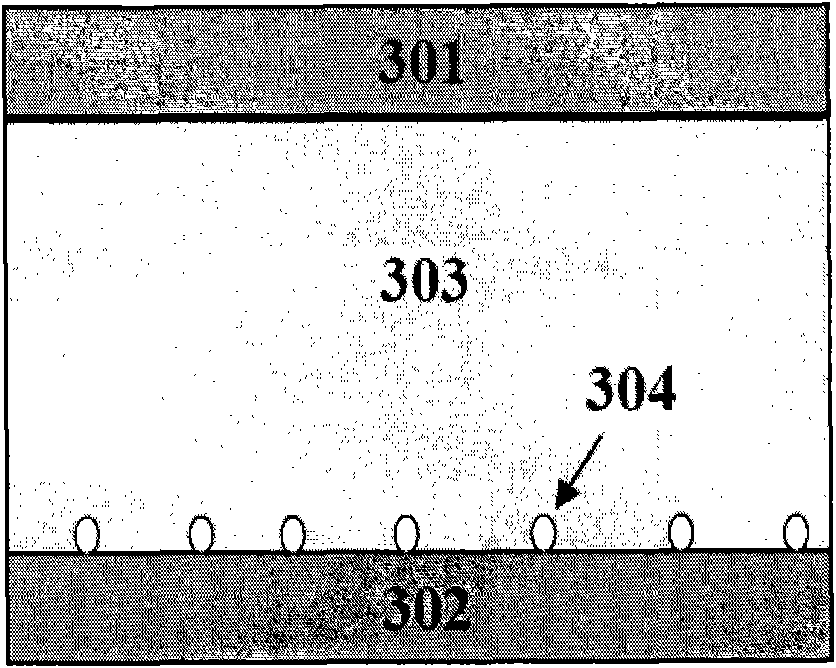

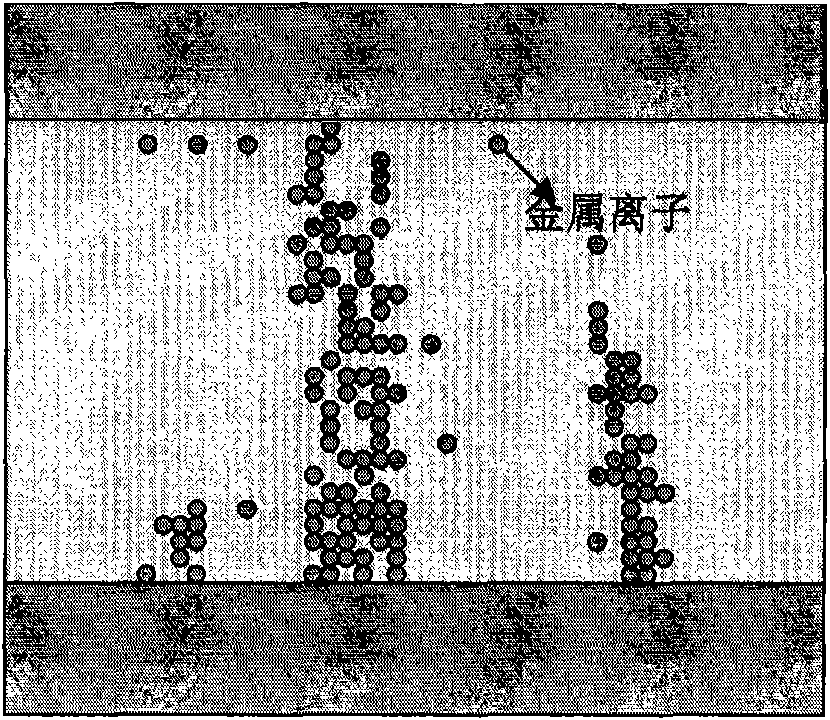

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0036] The process steps of the present invention to make the resistive non-volatile memory device are as follows:

[0037] 1) Using electron beam evaporation or magnetron sputtering to deposit conductive electrode metal on the insulating substrate, the thickness of the metal electrode layer is 100-500nm;

[0038] 2) Deposit a metal film with a thickness of several nm on the lower conductive electrode material by means of evaporation, sputtering, atomic layer deposition, etc., and then form the metal nanocrystal by rapid thermal annealing or high temperature thermal annealing; or use sol -Gel method to form metal nanocrystals. The specific operation method is to transfer the solution containing metal nanocrystal particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com