Cellulose acylate laminate film, method for producing cellulose acylate laminate film, polarizer and liquid crystal display device

一种纤维素酰化物、层合薄膜的技术,应用在纤维素酰化物层合薄膜和生产纤维素酰化物层合薄膜领域,能够解决没有研究薄膜延迟波长色散性能、背景黑色表现不可能、视角狭窄等问题,达到改善波长色散性能、解决色移问题、生产成本低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

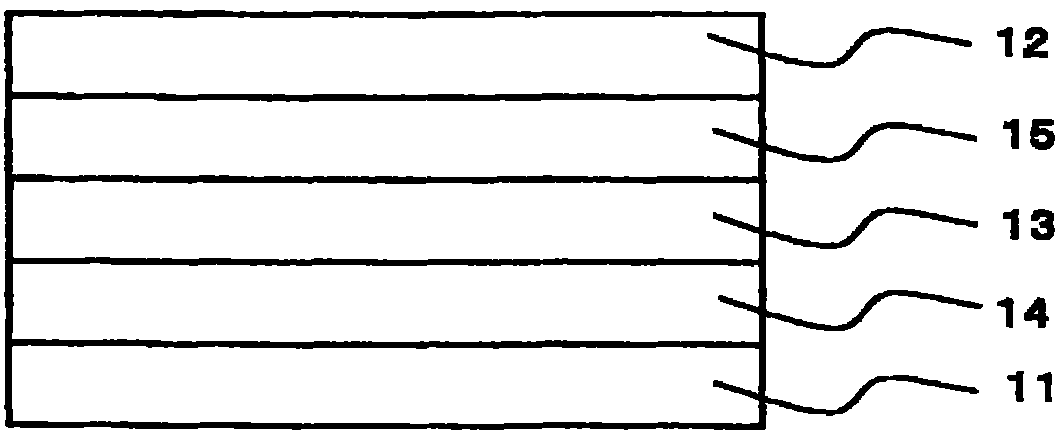

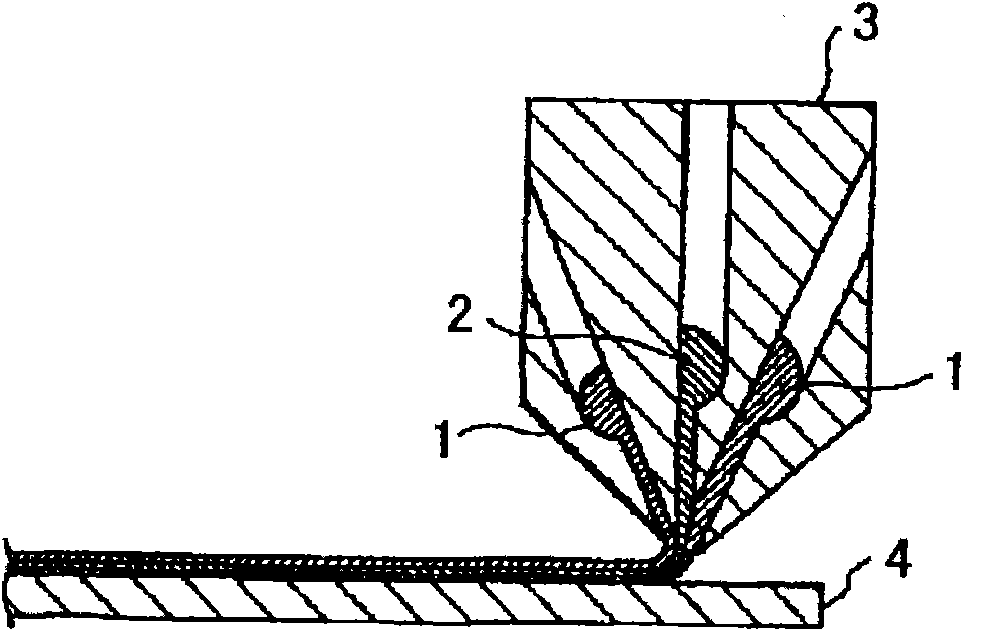

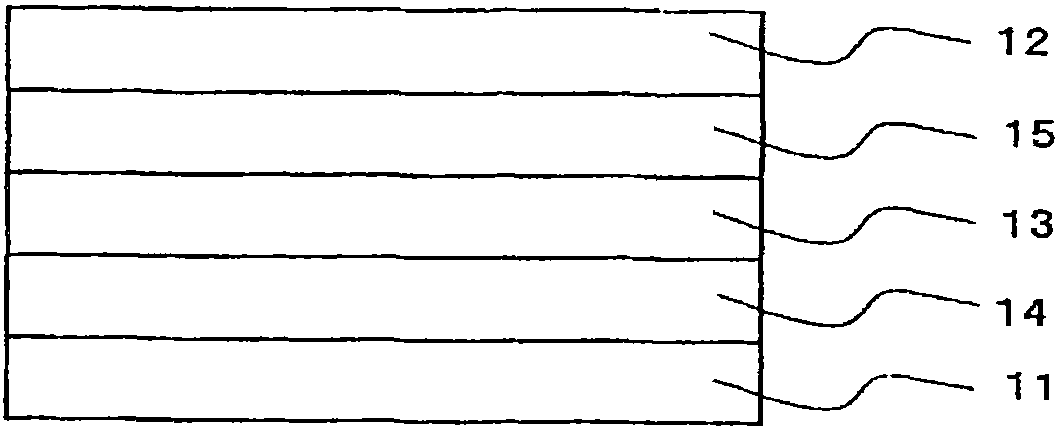

Image

Examples

preparation example Construction

[0082] The most common industrial synthesis method of mixed fatty acid esters of cellulose includes: using fatty acids corresponding to acetyl groups and other acyl groups (such as acetic acid, propionic acid, valeric acid, etc.) or mixed organic acid components containing their anhydrides carry out acylation.

[0083] From the viewpoint of retarded wavelength dispersion properties of the film, in the film of the present invention, the cellulose acylate used for the low substitution layer preferably satisfies the following formulas (3) and (4)

[0084] (3) 1.0

[0085] Wherein, X1 represents the substitution degree of the acetyl group of the cellulose acylate of the low substitution layer,

[0086](4) 1.0≤Y1<1.5

[0087] Here, Y1 represents the sum of the degrees of substitution of the acyl groups having at least 3 carbon atoms in the cellulose acylate of the low-substituted layer.

[0088] For Z1 in formula (1), X1 and Y1 satisfy X1+Y1=Z1.

[0089] From the viewpoi...

Embodiment

[0300] The following examples are given to describe the present invention more specifically. In the following examples, materials, reagents and substances used, their usage amounts and ratios, treatment contents and treatment procedures, etc. can be appropriately changed as long as they do not depart from the gist of the present invention. Therefore, the scope of the present invention should not be limitedly interpreted to the Examples shown below.

[0301] (Preparation of Cellulose Acylate)

[0302] Cellulose acylate was prepared according to the methods described in JP-A 10-45804 and 08-231761, and its degree of substitution was measured. Specifically, sulfuric acid (7.8 parts by mass relative to 100 parts by mass of cellulose) was added as a catalyst, carboxylic acid was added as a raw material of an acyl substituent, and an acylation reaction was performed at 40°C. In this process, the type and degree of substitution of the acyl group are adjusted by adjusting the type a...

Embodiment 34

[0388] Except that the solution C01 was diluted to a viscosity of about 30 Pa·s and the solution C01 was diluted to a viscosity of at least about 60 Pa·s., using the same conditions as in Example 2, casting the above-mentioned Table 1 for Cellulose acylate solution C01 for the low substitution layer and cellulose acylate solution S02 for the high substitution layer. Finally, a film sample was prepared, but it required a huge load to peel it off the tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com