Method for separating rare earth sulfate solution by saponifiable extraction

A rare earth sulfate extraction technology, applied in the field of metallurgy and chemical industry, to achieve the effects of reducing separation consumption, improving quality and stabilizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

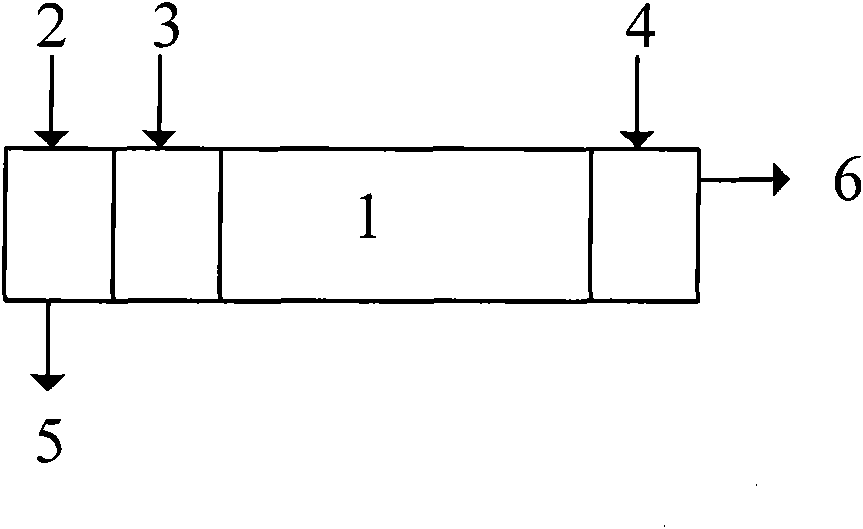

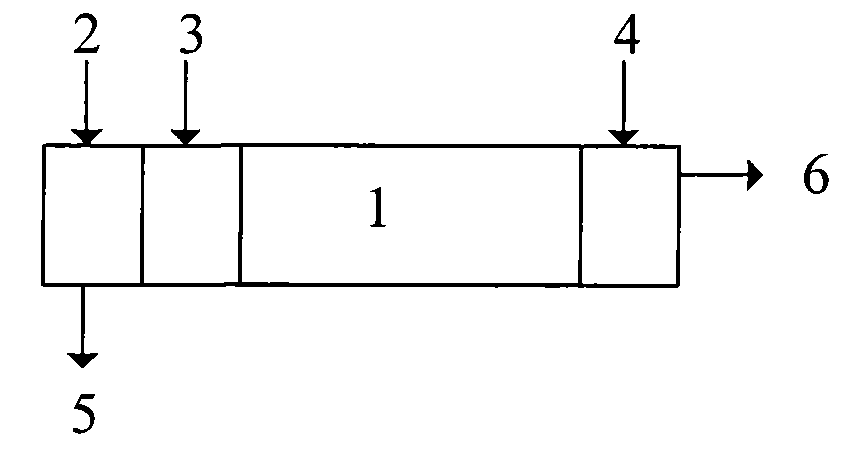

Image

Examples

Embodiment 1

[0047] Embodiment 1. carry out extraction and separation experiment in 8 grades of 300L extraction tanks, extraction agent is P204-kerosene, and feed liquid is the Baotou mine sulfate rare earth solution after magnesia neutralization. The organic phase is added to the first stage of the extraction tank, the saponification agent is sodium hydroxide and added to the second stage of the extraction tank, the third to sixth stages are the blocking agent magnesium sulfate solution, and the magnesium-containing rare earth sulfate is added as the soap material at the eighth stage. The results show that the rare earth sulfate double salt is not formed in the extraction tank, the production process can continue continuously, and the organic phase rare earth loading can meet the production requirements.

Embodiment 2

[0048] Embodiment 2. Carry out extraction separation experiment in 10 grades of 100L extraction tanks, extraction agent is P507-kerosene. The feed solution is sulfuric acid leaching solution of NdFeB waste material containing divalent iron element. All extraction tanks are sealed to prevent oxidation of ferrous iron. The organic phase is added to the first stage of the extraction tank, the saponification agent is ammonia water and added to the second stage of the extraction tank, the third to eighth stages are the blocking agent magnesium sulfate and ferrous sulfate solution, and the rare earth sulfate containing ferrous iron is added at the tenth stage as Soap material. The results show that no rare earth sulfate double salt is formed in the extraction tank, the production process can continue, and the organic phase rare earth load meets the production requirements.

Embodiment 3

[0049] Embodiment 3. Carry out extraction and separation experiments in 10-stage 100L extraction tanks, the extraction agent is P204-P507-kerosene, and the feed liquid is samarium-europium-gadolinium sulfate. The organic phase is added to the first stage of the extraction tank, and the saponification agent is ammonia water-sodium hydroxide mixed solution is added to the second stage of the extraction tank, and the third to eighth stages are blocking agents aluminum sulfate and magnesium sulfate solutions, and aluminum-containing sulfuric acid is added to the tenth stage Rare earth solution, the results show that no rare earth sulfate double salt is formed in the extraction tank, the production process can continue, and the organic phase rare earth load meets the production requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com