Multifunctional reaction tank and purification process thereof for flue gas desulfurization and denitrification

A desulfurization and denitrification, multi-functional technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of low quality of by-product ammonium sulfate, small gas-liquid contact area, low utilization rate of air oxygen, etc. Aerosol formation, investment savings, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

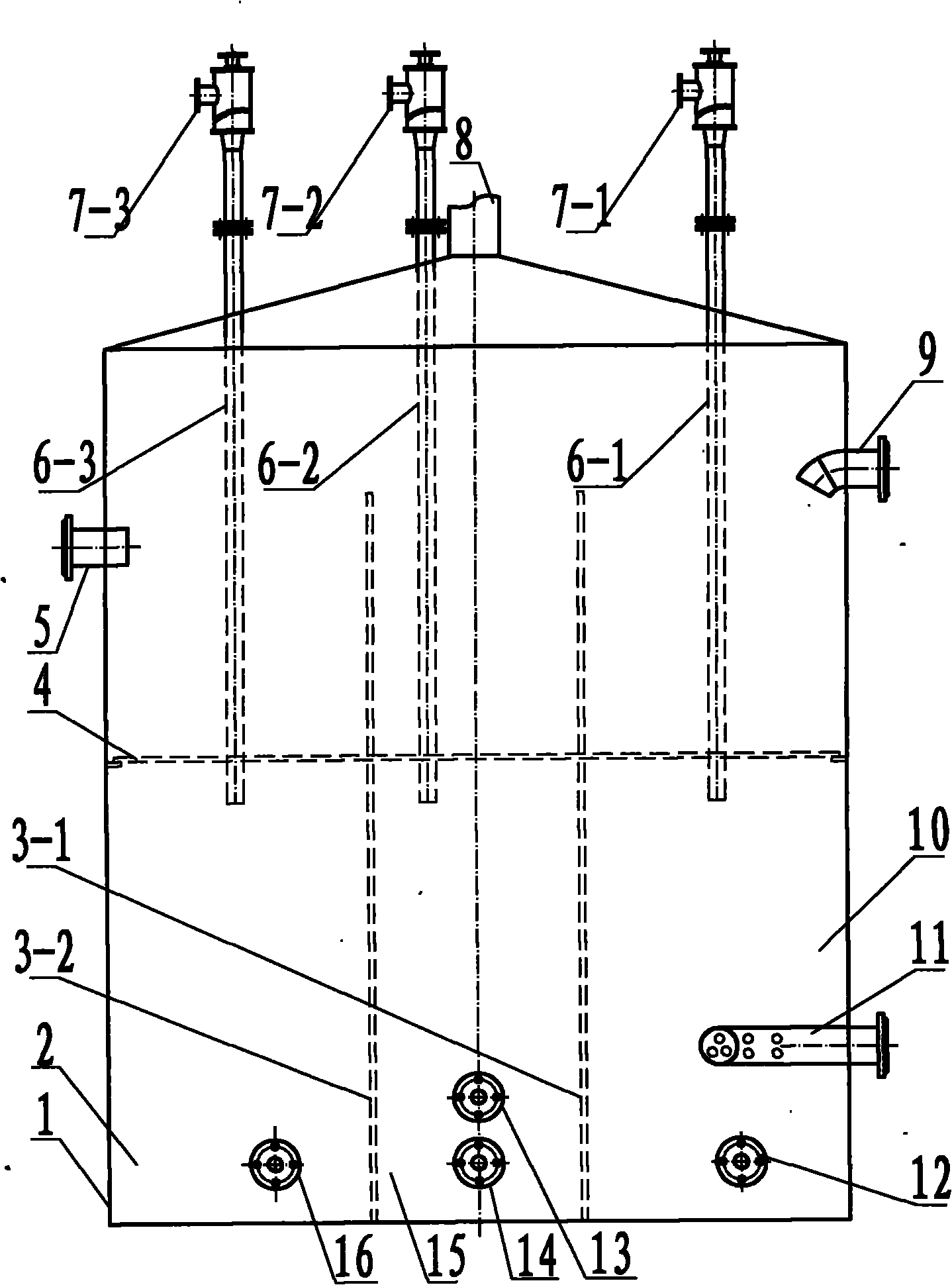

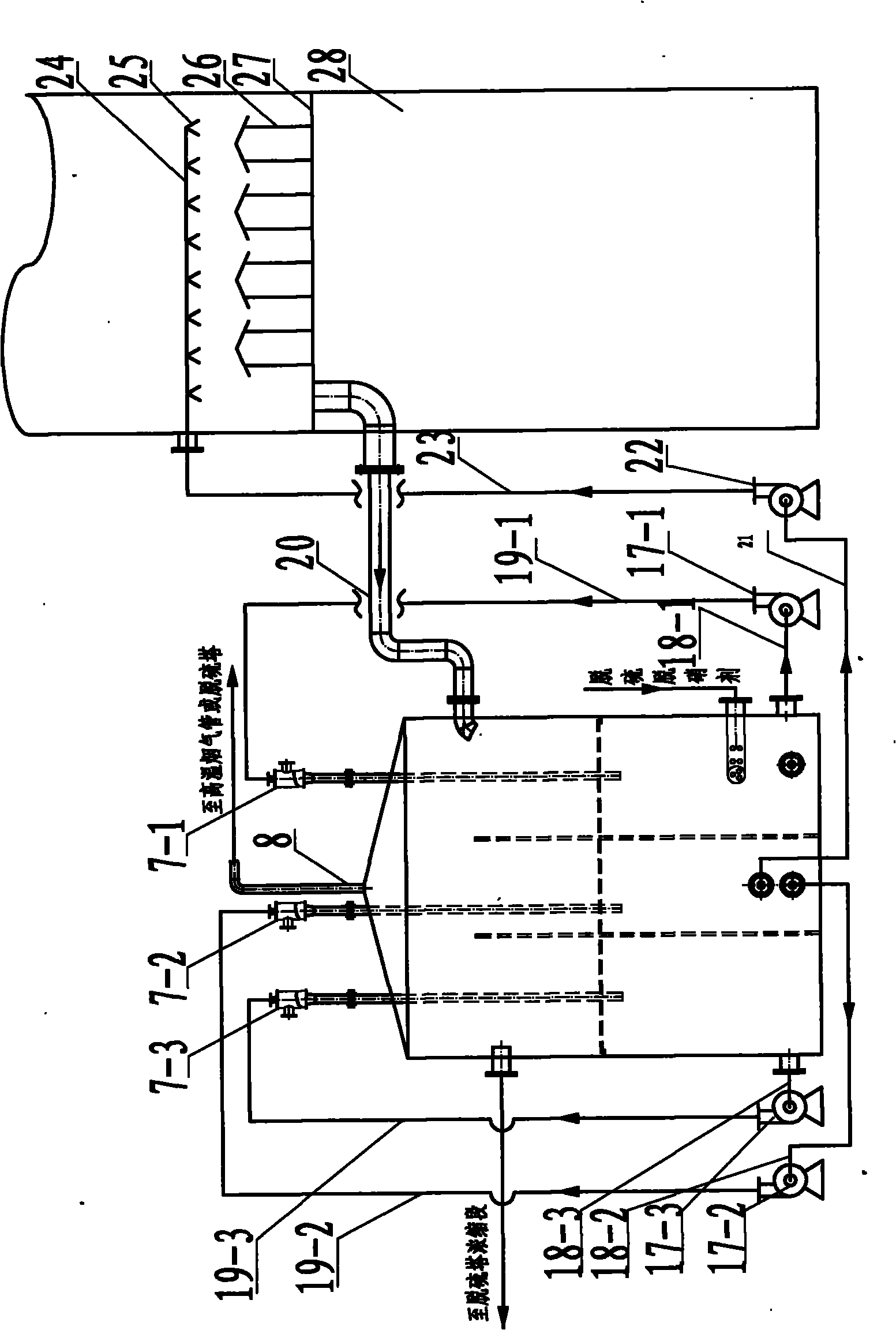

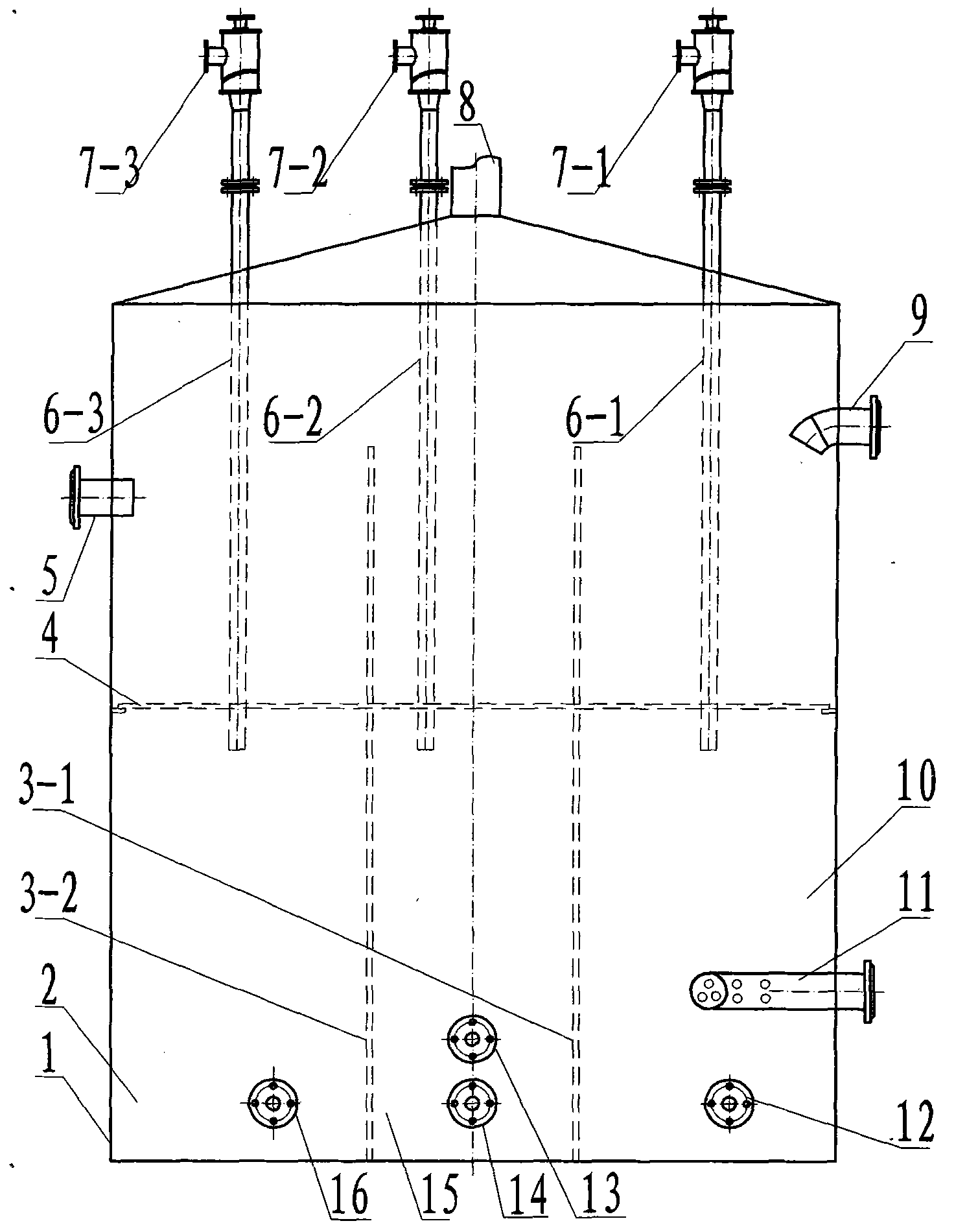

[0012] The present invention is described in conjunction with the accompanying drawings and specific embodiments. The following embodiments take the three-stage oxidation inner cavity as an example, but the present invention is not limited to the following embodiments;

[0013] Such as figure 1 , figure 2 As shown, a multifunctional reaction tank for flue gas desulfurization and denitrification, the multifunctional reaction tank has a tank body 1; two partitions 3-1, 3-2 are vertically arranged in the tank body 1, forming The structure of three oxidation inner cavities in one tank, and the two adjacent oxidation inner cavities communicate with each other; the upper part of each oxidation inner cavity is respectively equipped with a self-absorbing air jet gas-liquid mixer 7-1 , 7-2, 7-3, the lower part is respectively provided with oxidizing liquid outlets 12, 14, 16; each of the oxidizing liquid outlets 12, 14, 16 is respectively connected through connecting pipes 18-1, 18-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com