Preparation method of polypyrrole/ graphene composite material

A composite material, graphene technology, used in cable/conductor manufacturing, carbon-silicon compound conductors, organic material conductors, etc., can solve the problems of short life, high cost of carbon nanotubes, and low specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

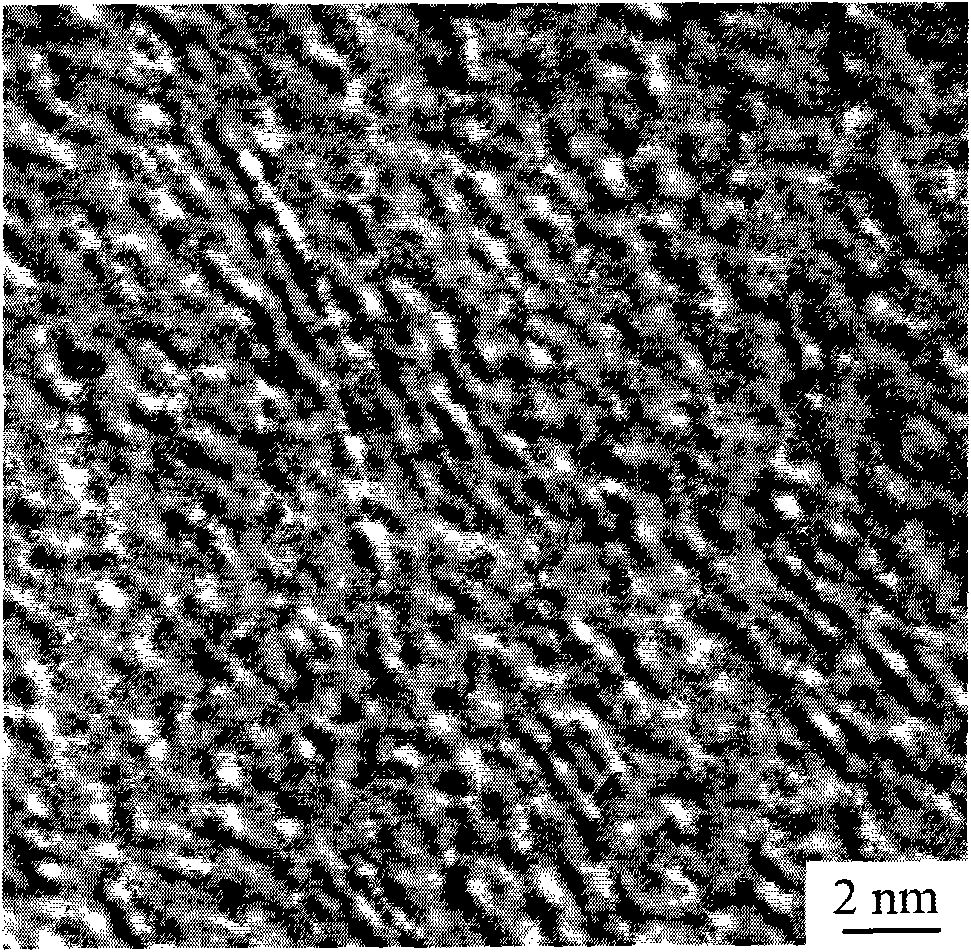

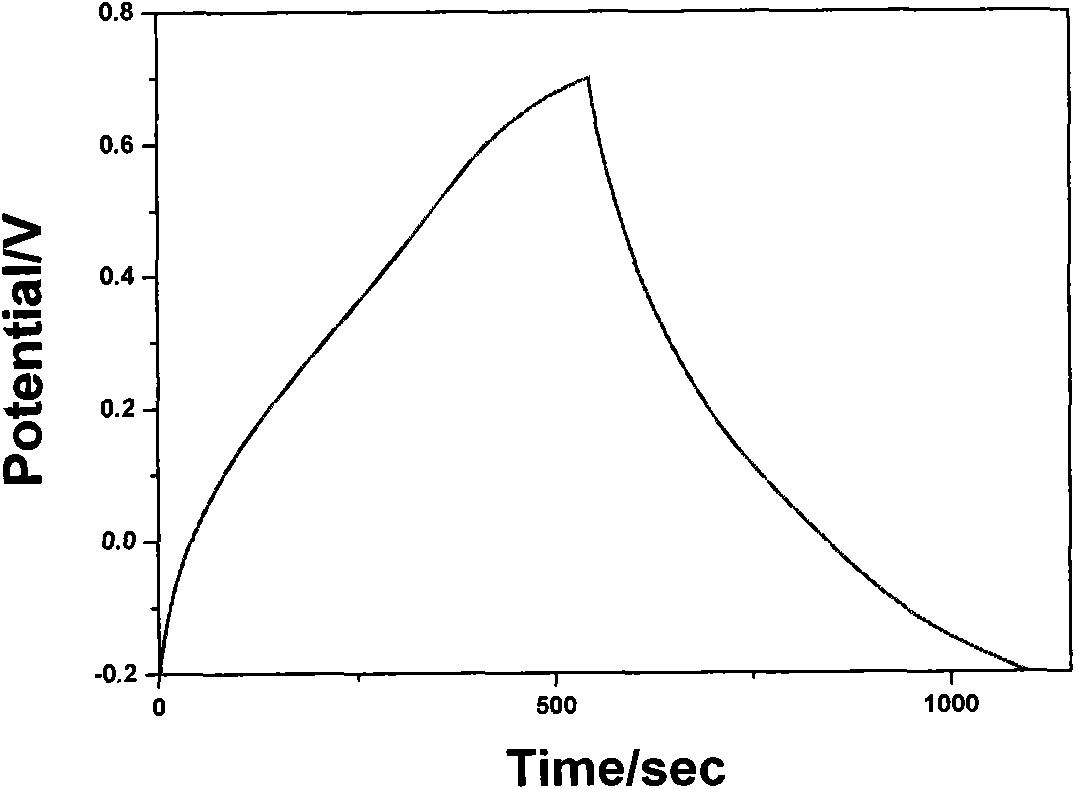

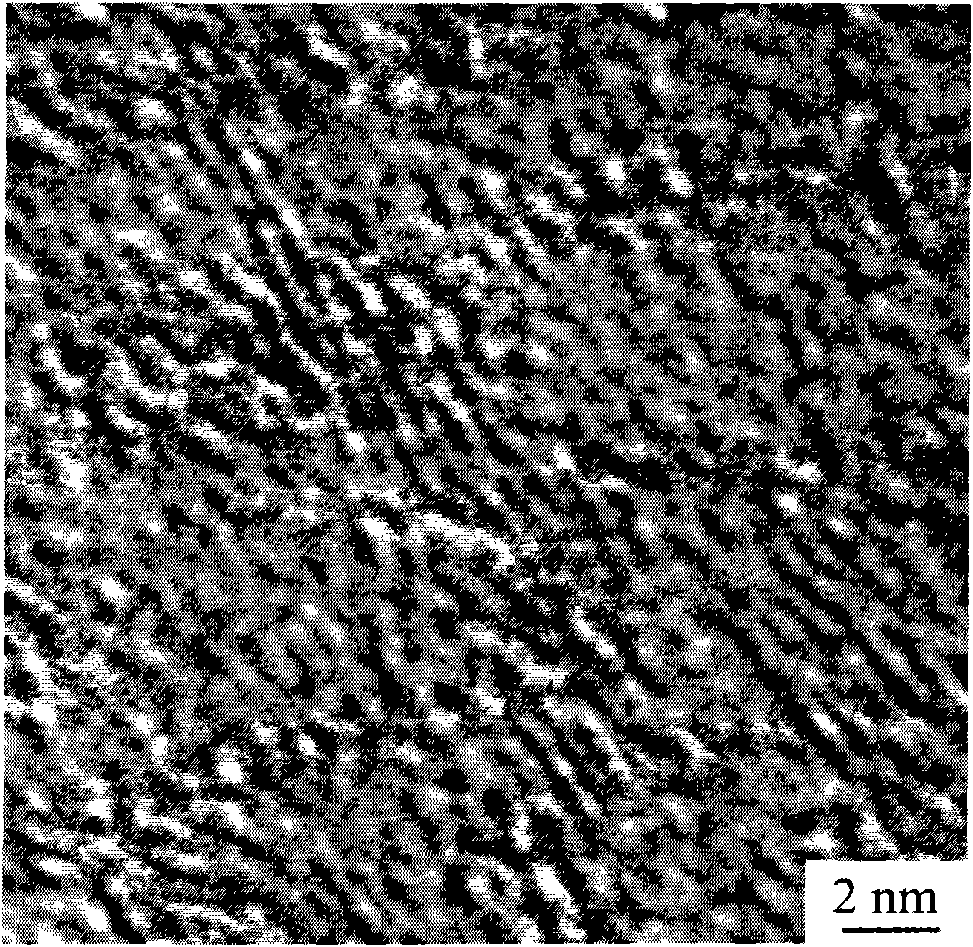

Image

Examples

Embodiment 1

[0017] (1) Reduction of graphene oxide: get 0.05g of graphite oxide and dissolve it in 50mL of water for ultrasonication for 120 minutes to form a graphene oxide solution with a mass concentration of 1g / L, add 0.25mL of hydrazine hydrate dropwise to the graphene oxide solution, and then add Slowly add ammonia water to the mixed solution to adjust the pH value to 8.0, and react in an oil bath at 95°C for 24 hours. After the reaction is completed, the product is washed with water to obtain a graphene wet powder, and the graphene wet powder is placed in 50 mL of deionized water for ultrasonication. Disperse for 10 minutes to obtain a stably dispersed graphene colloid.

[0018] (2) Preparation of polypyrrole / graphene composite material: take all the graphene colloids prepared in step (1) and 5g of pyrrole monomer and mix with ultrasound for 60 minutes, pour the mixed solution into a round bottom flask and stir in an ice bath 10 minutes, while 15gFeCl 3 ·6H 2 O dissolved in 150mL...

Embodiment 2

[0021] (1) Reduction of graphene oxide: Dissolve 0.05g of graphite oxide in 60mL of water, ultrasonicate for 110 minutes, configure a graphene oxide solution with a mass concentration of 0.83g / L, add 0.32mL of hydrazine hydrate dropwise to the graphene oxide solution, Then slowly add ammonia water to the mixed solution to adjust the pH value to 8.5, and react for 24 hours under the condition of an oil bath (95° C.). Deionized water was ultrasonically dispersed for 10 minutes to obtain stable dispersed graphene colloids.

[0022] (2) Preparation of polypyrrole / graphene composite material: take all the graphene colloids prepared in step (1) and 0.45g pyrrole monomer and mix with ultrasound for 55 minutes, pour the mixed solution into a round bottom flask and place it in an ice bath Stir for 10 minutes while adding 10 g FeCl 3 ·6H 2 O dissolved in 100mL of 0.1mol / L hydrochloric acid mixed solution was slowly added dropwise to the round-bottomed flask, and after the dropwise add...

Embodiment 3

[0026] (1) Reduction of graphene oxide: Dissolve 0.05g of graphite oxide in 70mL of water, ultrasonicate for 100 minutes, configure a graphene oxide solution with a mass concentration of 0.71g / L, add 0.36mL of hydrazine hydrate dropwise to the graphene oxide solution, Then slowly add ammonia water to the mixed solution to adjust the pH value to 8.8, and react for 24 hours under the condition of an oil bath (95° C.). After the reaction is completed, the product is washed with water to obtain a graphene wet powder. Ultrasonic dispersion in deionized water for 15 minutes resulted in stable dispersed graphene colloids.

[0027] (2) Preparation of polypyrrole / graphene composite material: take all the graphene colloids prepared in step (1) and 0.2g pyrrole monomer and mix with ultrasound for 45 minutes, pour the mixed solution into a round bottom flask and place it in an ice bath Stir for 10 minutes while adding 9 g FeCl 3 ·6H 2 O dissolved in 90mL of 0.1mol / L hydrochloric acid mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com