Method and device for removing barrier layer

A technology of barrier layer and metal layer, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as damage to copper, etching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

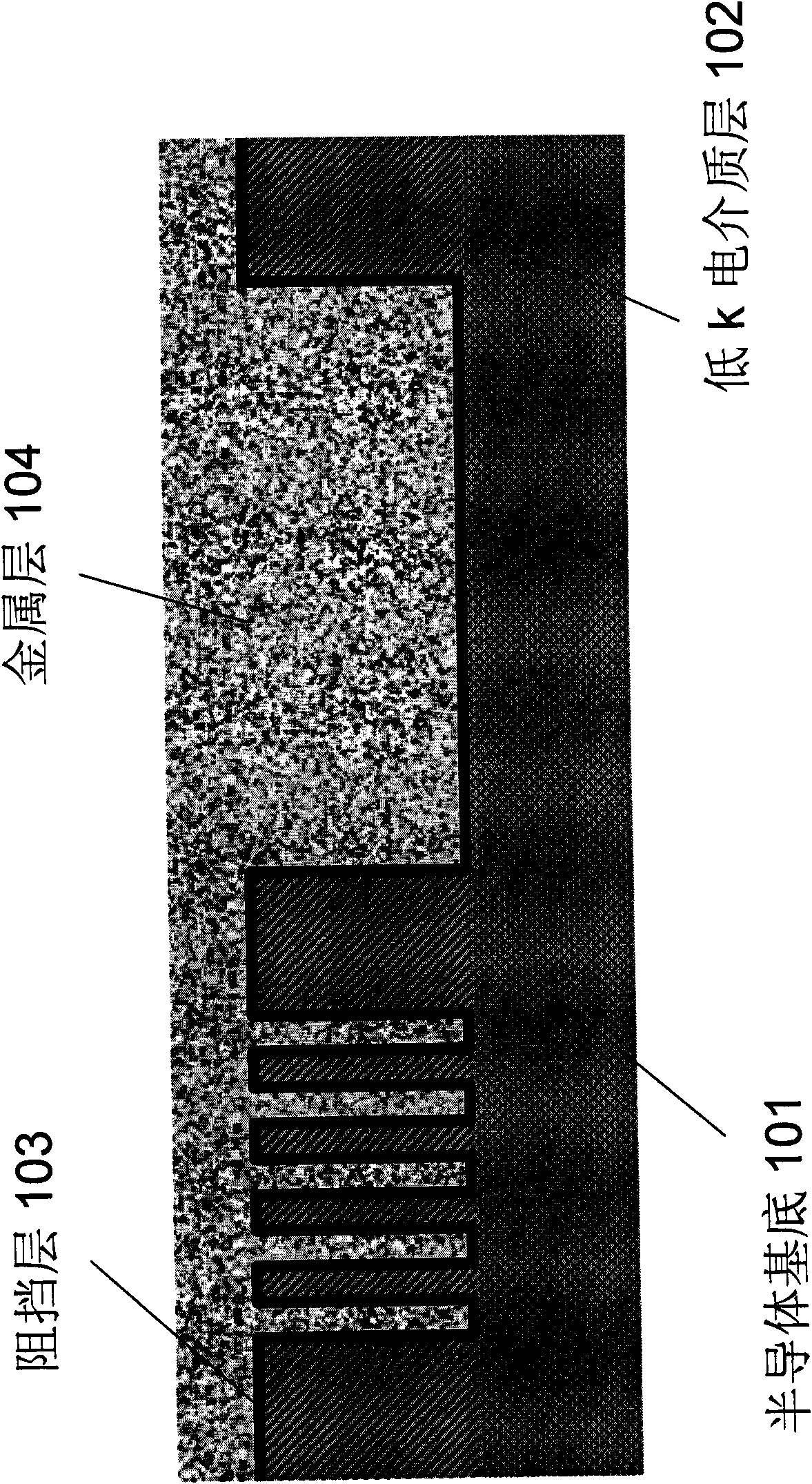

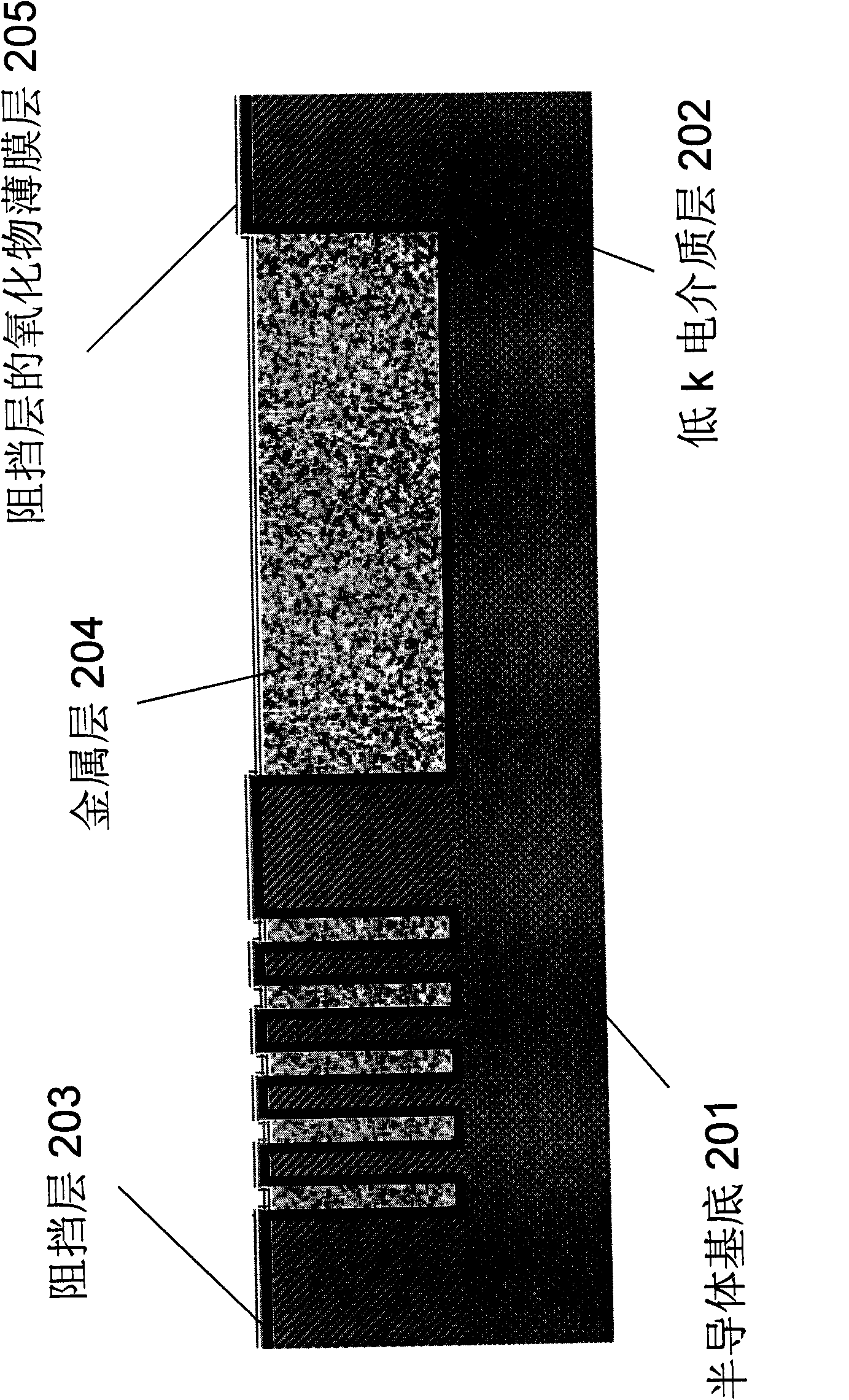

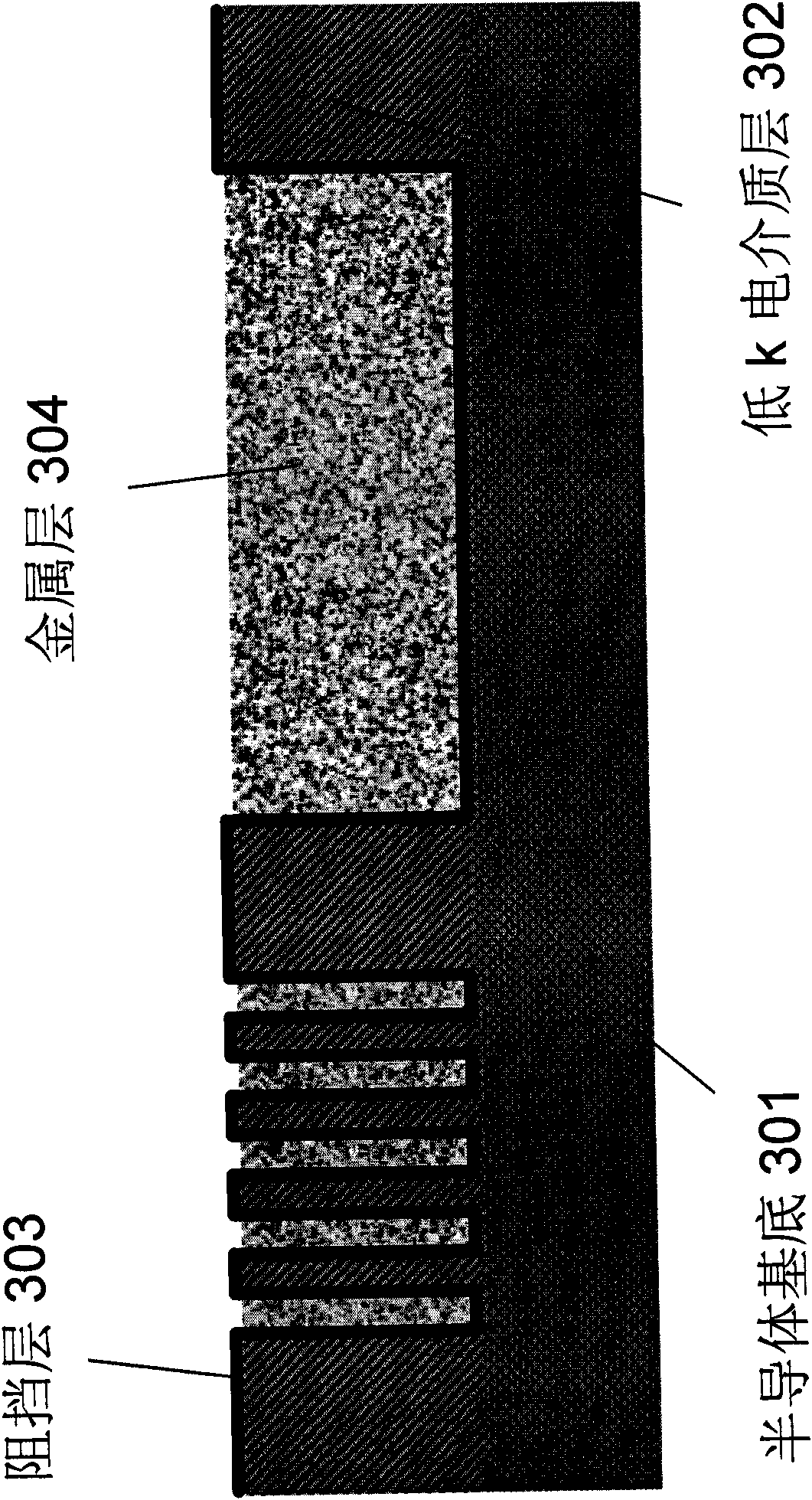

[0024] The present invention relates to a semiconductor device processing method and device. More specifically, the present invention relates to removing or etching barrier layers, such as tantalum / tantalum nitride, suitable for low-k dielectric materials. This facilitates various applications of low-k materials in semiconductor devices.

[0025] Figure 1 to Figure 4 Shown is the combination of some new processes in semiconductor processing: copper removal by stress-free polishing, etchant to remove tantalum oxide formed on the surface of the barrier layer during copper polishing, and selective xenon difluoride gas The barrier layer tantalum / tantalum nitride is removed by etching. Among them, no matter the electrochemical copper throwing, the removal of tantalum oxide, or the etching barrier layer of xenon difluoride are all processes without mechanical force. This set of processes thus minimizes mechanical damage to the semiconductor structure, minimizes blanketing effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com