Compound sulfate cement

A composite sulfate and cement technology, applied in the field of building materials, can solve the problems of easy cracking, unfavorable environmental protection and resource recycling, and high heat generation, and achieve excellent product performance, remarkable effects of energy saving, emission reduction and consumption reduction. good permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

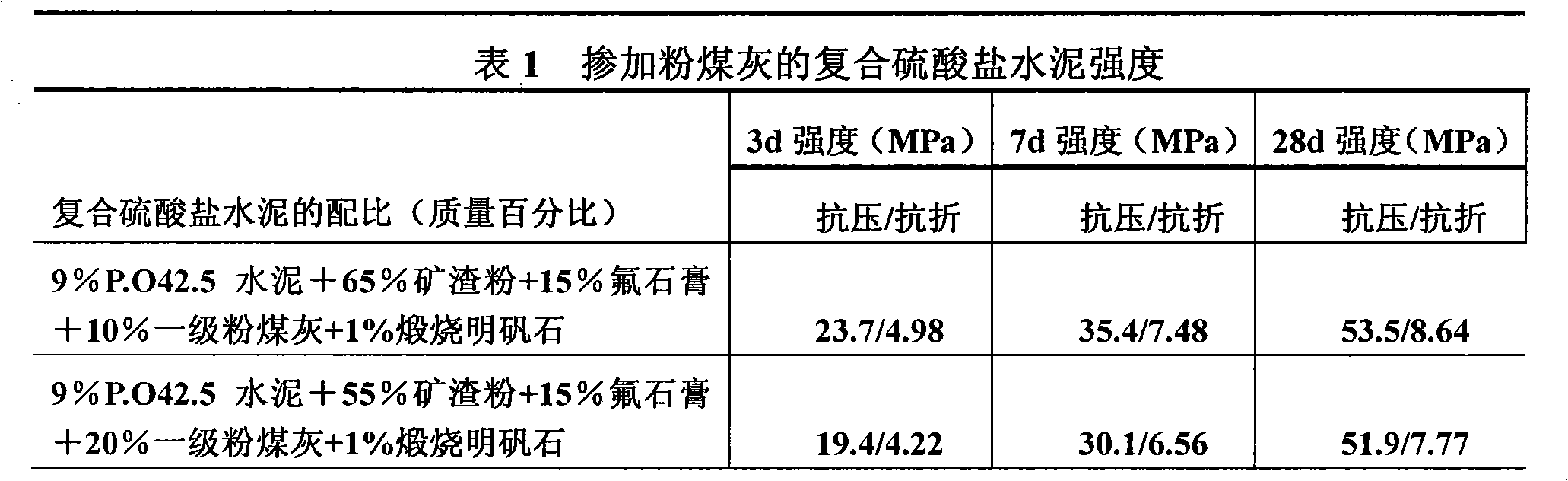

[0023] Grind the slag and fluorine gypsum separately until the specific surface area is 450m 2 / kg, 300m 2 / kg, mixed with P.O42.5 cement and first-grade fly ash evenly according to the ratio in Table 1, and carried out the mortar test according to the GB175-2008 standard, and measured the resistance of the specimens after standard curing for 3d, 7d, and 28d respectively. compressive and flexural strength.

[0024]

Embodiment 2

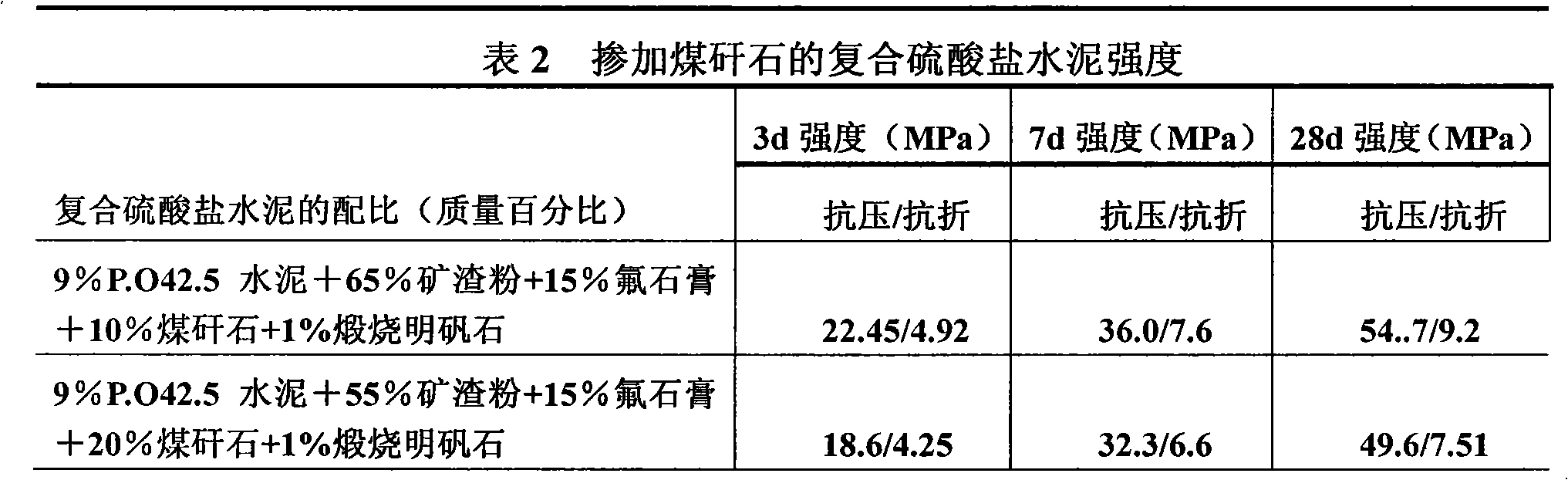

[0026] Grind the slag, coal gangue and fluorogypsum separately until the specific surface area is 450m 2 / kg, 350m 2 / kg, 300m 2 / kg, mix with P.O42.5 cement according to the ratio in Table 2, and carry out the mortar test according to the GB175-2008 standard, and measure the compressive and flexural strength of the standard culture specimens after 3d, 7d, and 28d.

[0027]

Embodiment 3

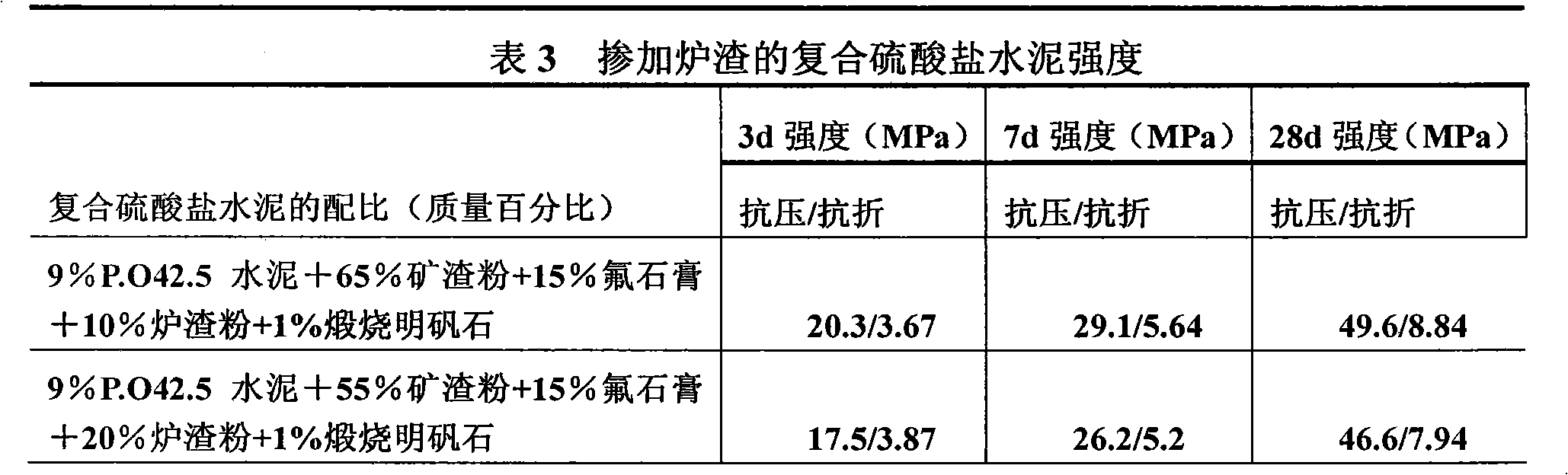

[0029] Grind the slag, slag and fluorogypsum separately until the specific surface area is 450m 2 / kg, 350m 2 / kg, 300m 2 / kg, according to the ratio in Table 3 and P.O42.5 cement and mixed evenly, according to the GB175-2008 standard to carry out the mortar test, and measure the compressive and flexural strength of the standard maintenance specimens for 3d, 7d, and 28d.

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com