Plant fiber cement-based block material and preparation method thereof

A plant fiber and cement-based technology, which is applied in the field of filling blocks, can solve the problems of poor quality, lack of toughness and ductility, and single block materials, and achieve low material prices, good ductility and energy consumption performance, and convenient material acquisition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

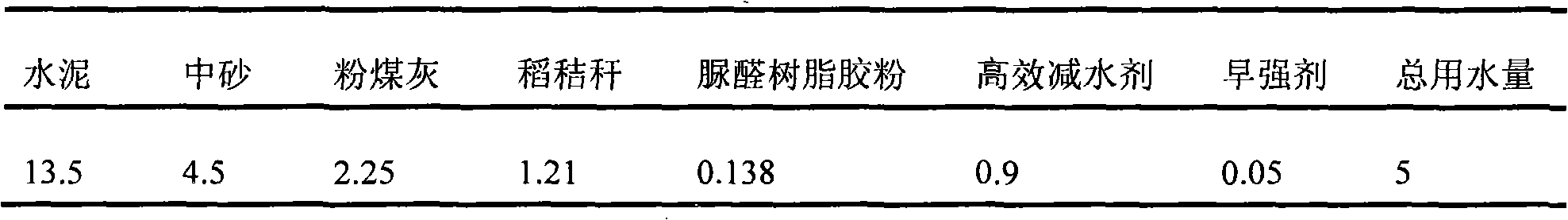

[0024] A raw material mix ratio for the production of plant fiber cement-based blocks:

[0025] Table 1 Mixing ratio of rice straw fiber cement-based block materials (kg)

[0026]

[0027] Step 1, weighing the material according to the composition and content of the rice straw fiber cement-based block material described in Table 1; the rice straw fiber is in the form of filaments with a length of 2-8 mm.

[0028] Step 2: adding the rice straw fiber and urea-formaldehyde resin rubber powder weighed in Step 1 into a mixer, and stirring for 1 minute.

[0029] Step 3: Add the cement, medium sand, and fly ash weighed in Step 1 to the mixture in Step 2, continue stirring for 2 minutes, and then add 2 / 3 of the total water consumption for stirring.

[0030] Step 4: Finally, add the high-efficiency water reducer, early strength agent and 1 / 3 of the total water consumption in step 1 and stir. After stirring for 3 minutes, discharge the material, pour it into the mold, and cure it fo...

Embodiment 2

[0033] A raw material mix ratio for the production of plant fiber cement-based blocks:

[0034] Table 2 Mixing ratio of rice straw fiber cement-based block materials (kg)

[0035]

[0036] Step 1, weighing the material according to the composition and content of the rice straw fiber cement-based block material described in Table 2;

[0037] Other processes are the same as Example 1, and the test results are: compressive strength: 3.3Mpa.

Embodiment 3

[0039] A raw material mix ratio for the production of plant fiber cement-based blocks:

[0040] Table 3 Mixing ratio of rice straw fiber cement-based materials (kg)

[0041]

[0042] Step 1, weighing the material according to the composition and content of the rice straw fiber cement-based block material described in Table 3;

[0043] Other processes are the same as Example 1, and the test results are: compressive strength: 5.0Mpa.

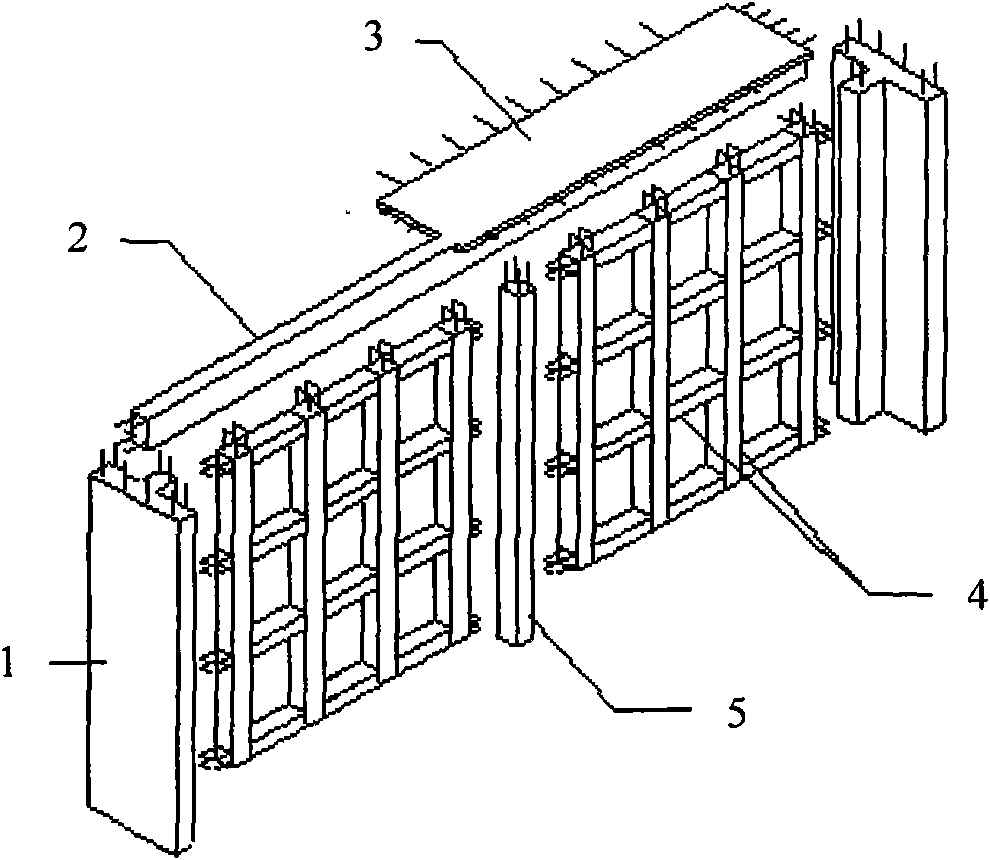

[0044] figure 1 It is a schematic diagram of the structure of the ribbed composite wall. The rib structure system is composed of outer frame column 1, outer frame beam 2, floor slab 3, concrete grid 4, and connecting column 5. The block of the present invention is filled in the concrete sash 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com