Ammonium nitrate modifier for electric blasting

A technology of ammonium nitrate and modifier, which is applied in the direction of explosives, etc., can solve the problem that the performance of explosives has no effect, and achieve the effects of improving drying effect, improving product quality, and modifying chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

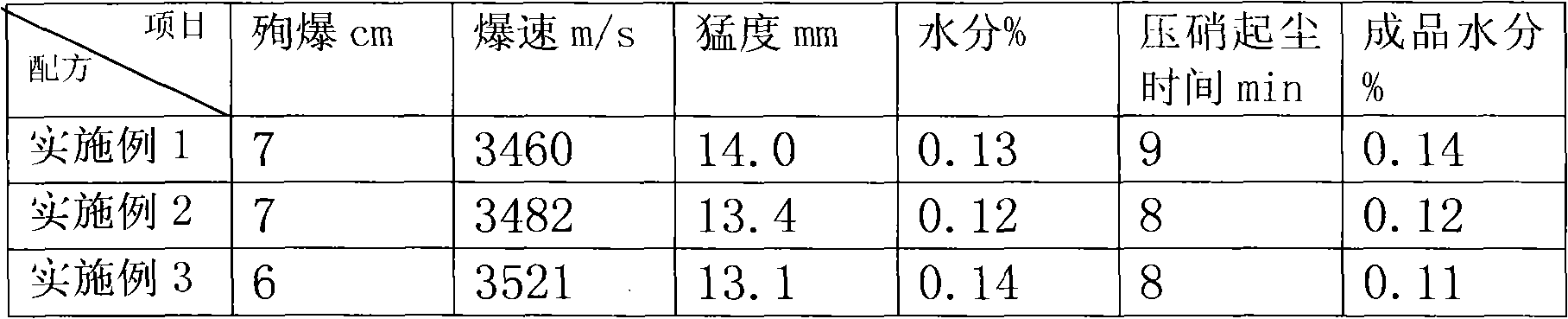

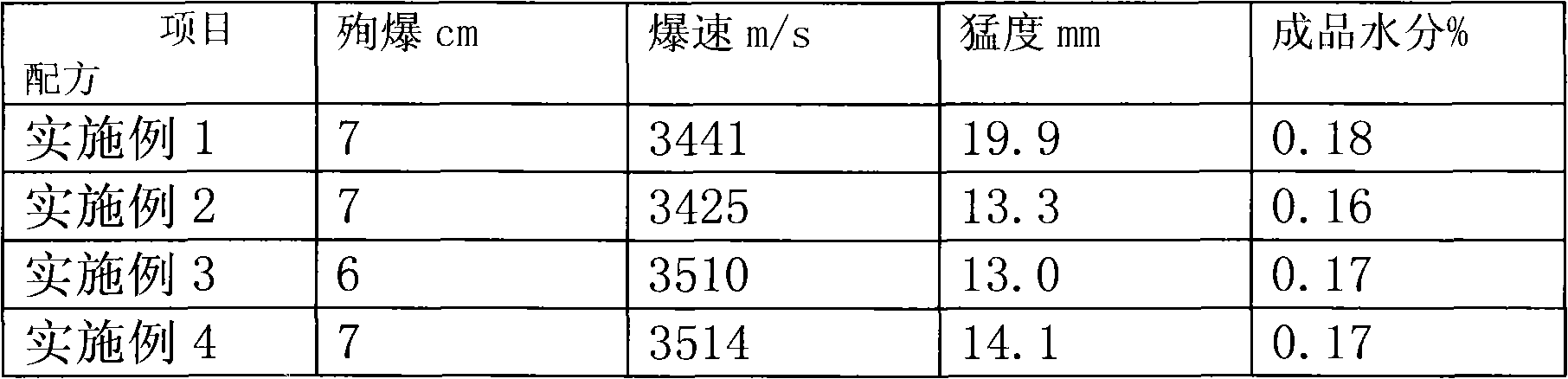

Embodiment 1

[0009] An ammonium nitrate modifier for electric blasting, which is prepared from raw materials containing the following weight ratio: 7Kg of octadecylamine, 20Kg of 14% phosphoric acid aqueous solution, chemical reaction is carried out at 85°C, dehydration is carried out with a dehydrator after the reaction, and then Dried in a dryer, and finally ball milled with a ball mill.

Embodiment 2

[0011] An ammonium nitrate modifier for electric blasting, prepared from raw materials containing the following weight proportions: 8Kg of octadecylamine, 22Kg of 16% phosphoric acid aqueous solution, chemical reaction is carried out at 86°C, dehydration is carried out with a dehydrator after the reaction, and then Dried in a dryer, and finally ball milled with a ball mill.

Embodiment 3

[0013] An ammonium nitrate modifier for electric blasting, prepared from raw materials containing the following weight ratio: 10Kg of octadecylamine, 25Kg of 20% phosphoric acid aqueous solution, chemical reaction is carried out at 90°C, dehydration is carried out with a dehydrator after the reaction, and then Dried in a dryer, and finally ball milled with a ball mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com