Polypropylene resin composite

A technology of polypropylene resin and composition, applied in the field of polypropylene resin composition, can solve the problems of flow marks, prolong the molding cycle, increase the production cost, etc., and achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Mix 68kg polypropylene, 20kg calcium carbonate, 0.3kg2-tert-butyl-4-methoxyphenol, 0.2kg4-hydroxyl-2,2,6,6-tetramethylpiperidine and 0.3kg calcium stearate Mix in the machine for 2min, the rotating speed of the mixer is 350 rpm; then add 12kgPOE and 0.2kg acrylate-maleic acid-ethylene terpolymer to it and continue mixing for 1.5min, the rotating speed of the mixer is 500 rpm Minutes, then transfer the material to a twin-screw extruder, melt and knead at 200°C, and obtain a polypropylene resin composition after extrusion. Wherein, the MFR of the polypropylene is 10g / 10min, and the Izod notched impact strength is 15kJ / m 2 .

[0048] The polypropylene resin composition was dried at 80°C for 2 hours, and a standard sample was obtained after injection molding by an injection machine. The molding process parameters were as follows:

[0049] Material temperature: 230°C for the first stage, 230°C for the second stage, 230°C for the third stage, 220°C for the fourth stage, and...

Embodiment 2

[0062] 68kg polypropylene, 10kg calcium carbonate, 10kg talcum powder, 0.4kg tris(2-isobutylphenyl) phosphite, 0.2kg2-(2'-hydroxyl-5'-methylphenyl)benzotriazole Mix 2min with 0.3kg titanate in the mixer, the rotating speed of the mixer is 350 rpm; then add 12kgPOE and 0.2kg1,2-epoxy-5-hexene-butadiene copolymer to it and continue mixing 1.5min, the rotational speed of the mixer is 600 rpm, and then the material is transferred to a twin-screw extruder, melted and kneaded at 200°C, and extruded to obtain a polypropylene resin composition. Wherein, the MFR of the polypropylene is 15g / 10min, and the Izod notched impact strength is 20kJ / m 2 .

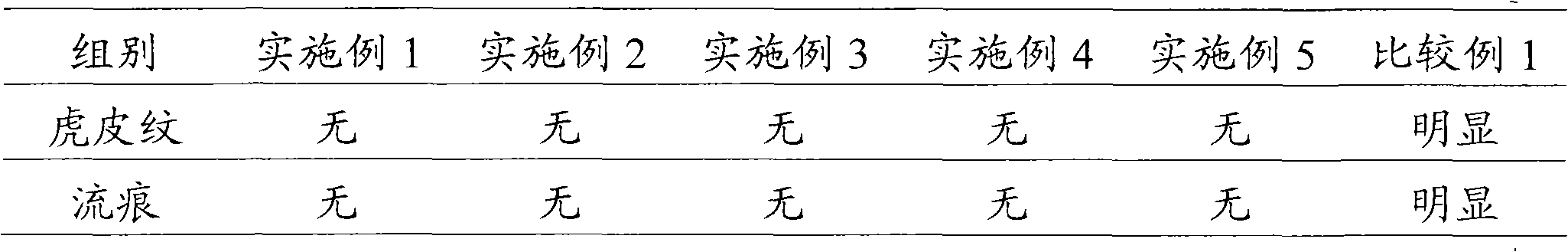

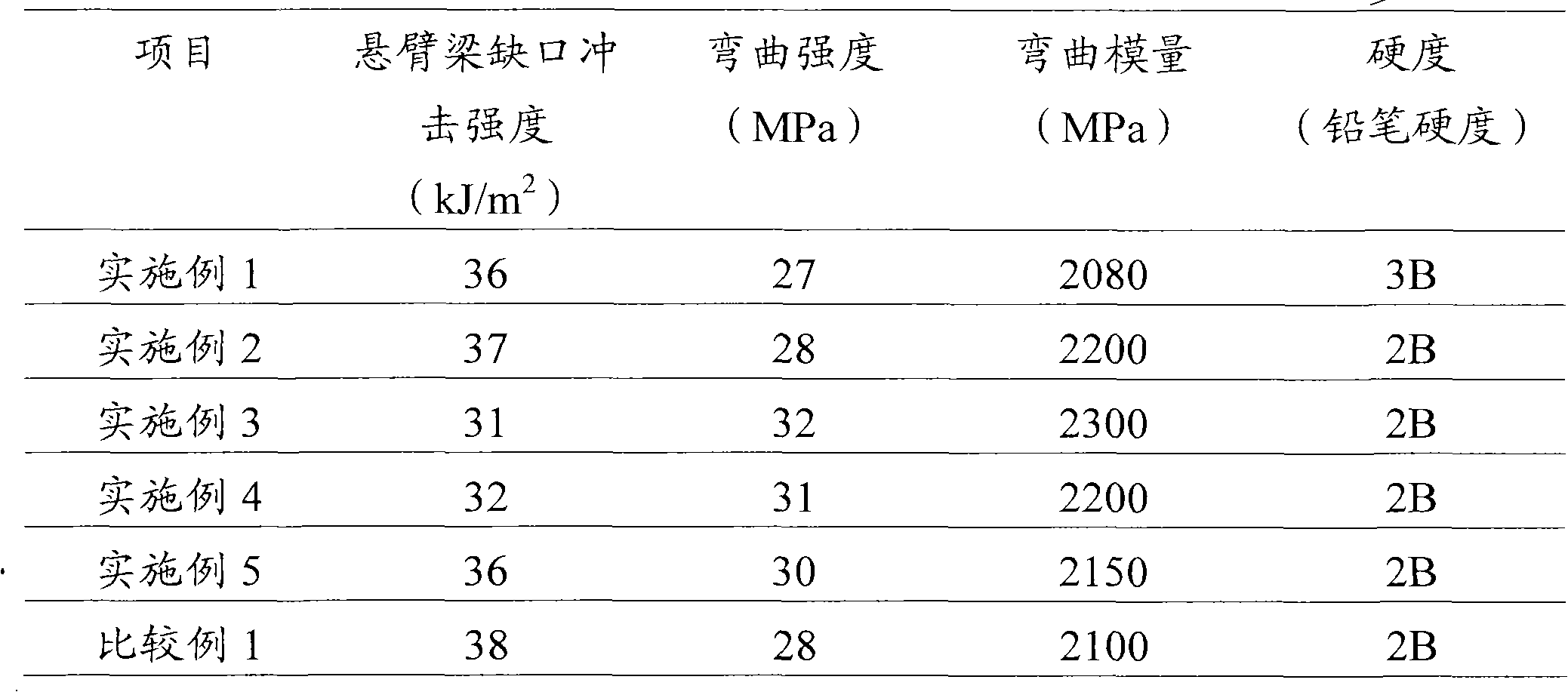

[0063] The polypropylene resin composition was dried at 80°C for 2 hours, and a standard sample was obtained after injection molding by an injection machine according to the process parameters provided in Example 1. The appearance of the standard sample was observed, and the results are shown in Table 1, Table 1. 1 is the appearance observ...

Embodiment 3

[0066] 61kg polypropylene, 15kg calcium carbonate, 10kg talcum powder, 0.3kg octadecyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 0.2kg2-(2'-hydroxy -5'-methylphenyl) benzotriazole and 0.3kg aluminate were mixed in a mixer for 2min, and the rotation speed of the mixer was 350 rpm; then 14kgSEBS and 0.2kg acrylate-trans-butene were added thereto The diacid-ethylene terpolymer continued to mix for 1.5min, the speed of the mixer was 600 rpm, and then the material was transferred to a twin-screw extruder, melted and kneaded at 200°C, and a polypropylene resin composition was obtained after extrusion. things. Wherein, the MFR of the polypropylene is 20g / 10min, and the notched Izod impact strength is 18kJ / m 2 .

[0067] The polypropylene resin composition was dried at 80°C for 2 hours, and a standard sample was obtained after injection molding by an injection machine according to the process parameters provided in Example 1. The appearance of the standard sample was observe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Izod notched impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com