Piperacillin sodium-tazobactam sodium medicinal composition microsphere injection

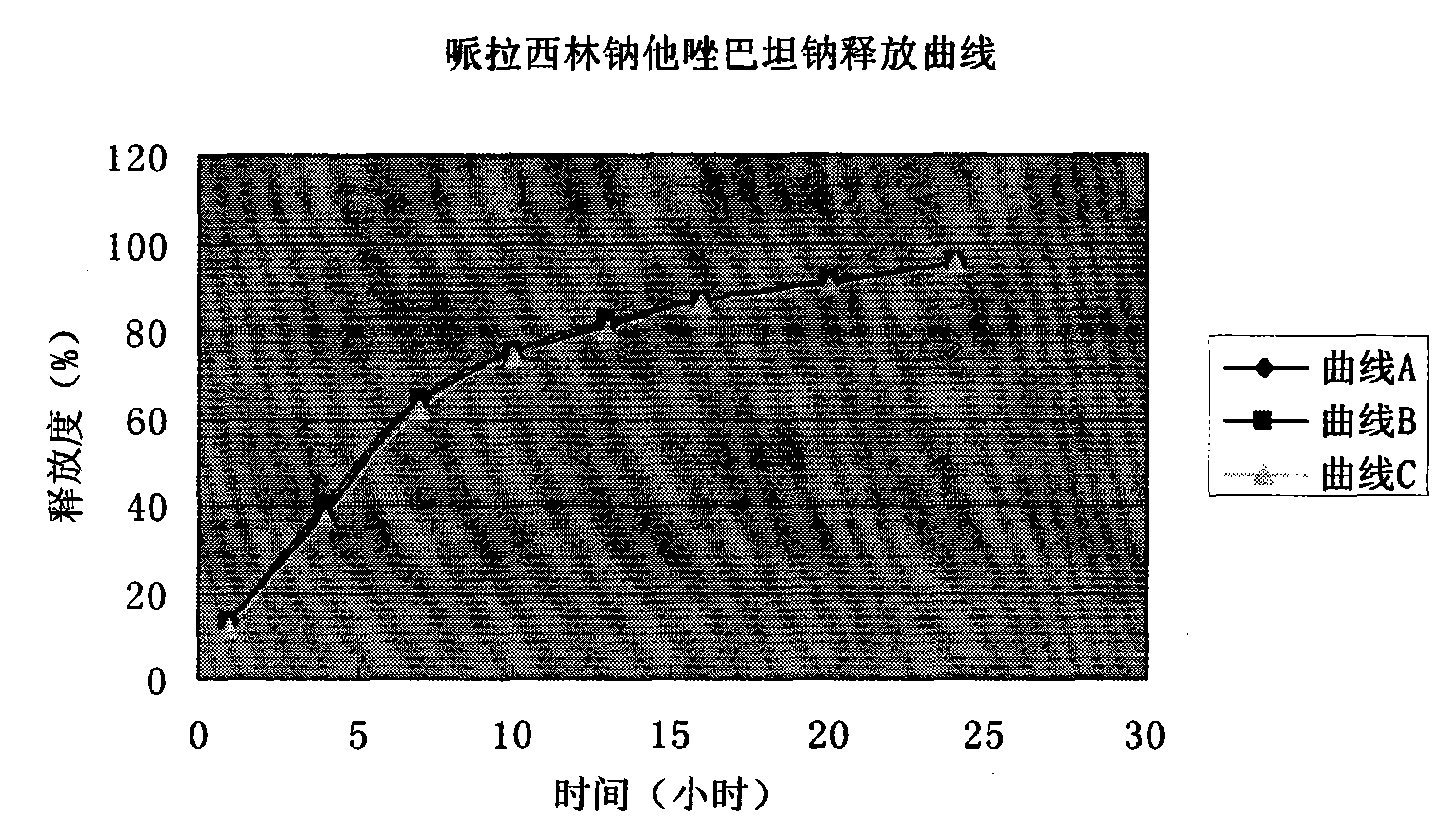

A technology of tazobactam sodium and piperacillin sodium, which is applied in the field of medicine and can solve problems such as easy adhesion and aggregation, difficulty in mass production, and large particle distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

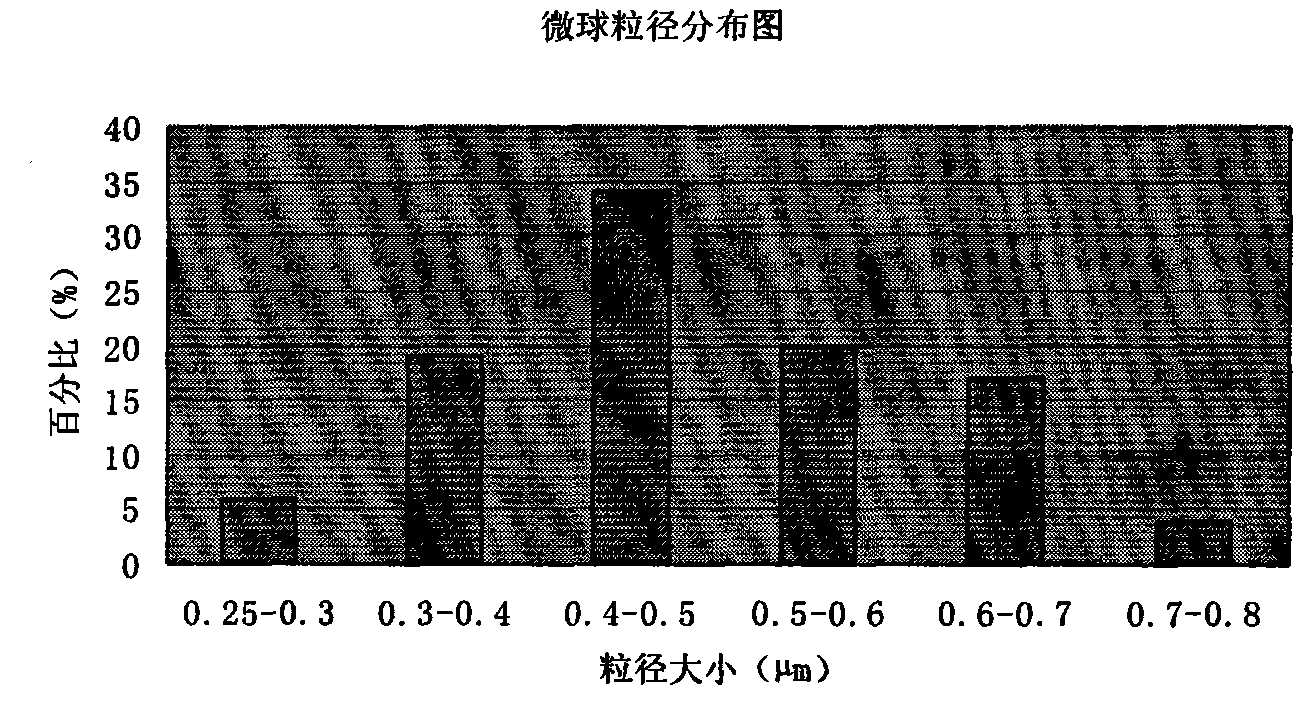

Embodiment 1

[0073] Example 1 Preparation of Piperacillin Sodium-Tazobactam Sodium Pharmaceutical Composition Microsphere Injection

[0074] Prescription: (100 bottles)

[0075] Piperacillin Sodium 40g

[0076] Tazobactam Sodium 10g

[0077] PLA-PEG 40g

[0078] PEG600 60g

[0079] Polysorbate 80 10g

[0080] Mannitol 20g

[0081] making process:

[0082] (1) 40g of piperacillin sodium, 10g of tazobactam sodium, 60g of PEG600 and 20g of mannitol were dissolved in 800ml of water for injection to obtain an aqueous phase;

[0083] (2) 40g PLA-PEG and 10g polysorbate 80 were dissolved in 200ml of dichloromethane to obtain an oil phase;

[0084] (3) Slowly drop the water phase obtained above into the oil phase under stirring conditions, stir for 10 minutes after dropping, then transfer to a high-speed homogenizer and stir at high speed for 3 times, each time for 10 minutes, to obtain a uniform white emulsion ;

[0085] (4) Put the white emulsion into the spray dryer, adjust the spray c...

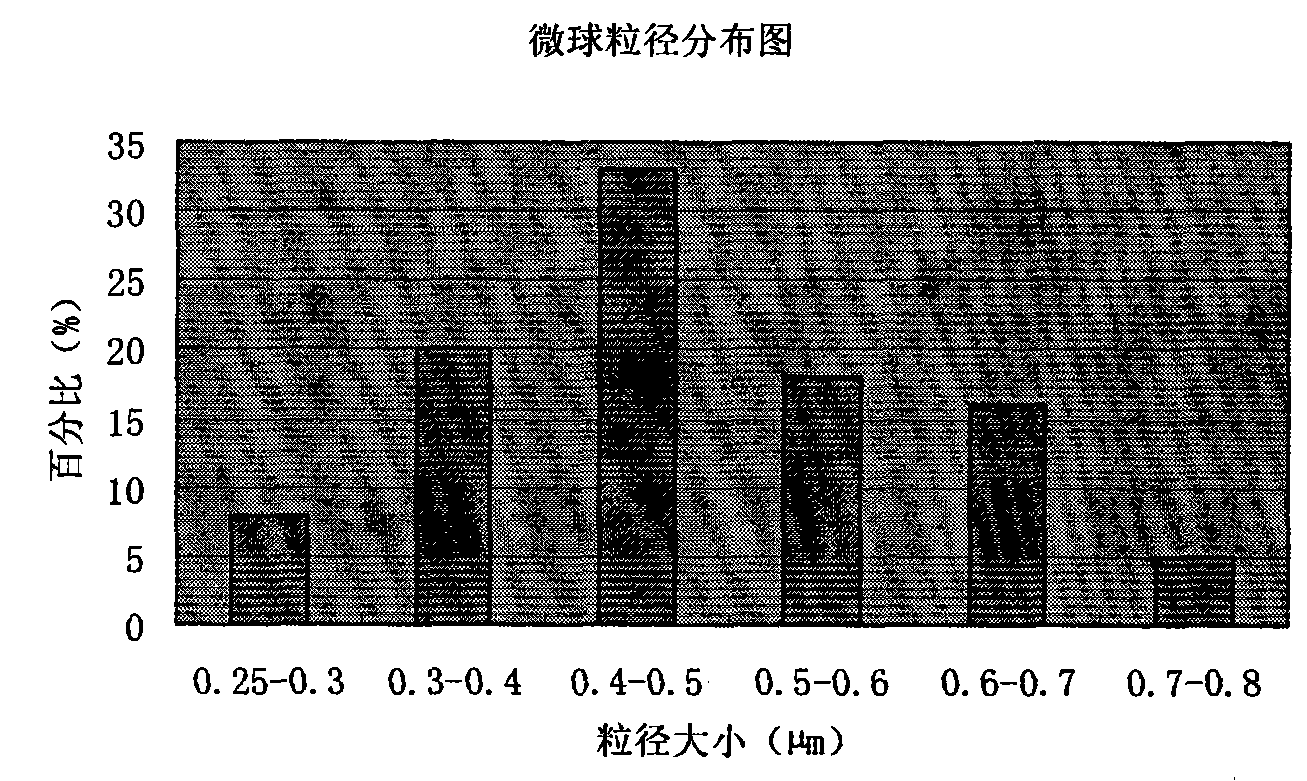

Embodiment 2

[0101] Example 2 Preparation of Piperacillin Sodium-Tazobactam Sodium Pharmaceutical Composition Microsphere Injection

[0102] Prescription: (100 bottles)

[0103] Piperacillin Sodium 80g

[0104] Tazobactam Sodium 10g

[0105] PLA-PEG 55g

[0106] PEG60070g

[0107] Polysorbate 80 15g

[0108] Mannitol 20g

[0109] making process:

[0110] (1) Dissolve 80g of piperacillin sodium, 10g of tazobactam sodium, 70g of PEG600 and 20g of mannitol in 1000ml of water for injection to obtain an aqueous phase;

[0111] (2) 55g PLA-PEG and 15g polysorbate 80 were dissolved in 300ml of toluene to obtain an oil phase;

[0112] (3) Slowly drop the water phase obtained above into the oil phase under stirring conditions, stir for 10 minutes after dropping, then transfer to a high-speed homogenizer and stir at high speed for 3 times, each time for 10 minutes, to obtain a uniform white emulsion ;

[0113] (4) Put the white emulsion into the spray dryer, adjust the spray conditions (inl...

Embodiment 3

[0129] Example 3 Preparation of Piperacillin Sodium-Tazobactam Sodium Pharmaceutical Composition Microsphere Injection

[0130] Prescription: (100 bottles)

[0131] Piperacillin Sodium 80g

[0132] Tazobactam Sodium 10g

[0133] PLA-PEG 60g

[0134] PEG600 65g

[0135] Polysorbate 80 22g

[0136] Mannitol 30g

[0137] making process:

[0138] (1) Dissolve 80g of piperacillin sodium, 10g of tazobactam sodium, 65g of PEG600 and 30g of mannitol in 1200ml of water for injection to obtain an aqueous phase;

[0139] (2) 60g PLA-PEG and 22g polysorbate 80 were dissolved in 400ml of acetone to obtain an oil phase;

[0140] (3) Slowly drop the water phase obtained above into the oil phase under stirring conditions, stir for 10 minutes after dropping, then transfer to a high-speed homogenizer and stir at high speed for 5 times, each time for 10 minutes, to obtain a uniform white emulsion ;

[0141] (4) Put the white emulsion into the spray dryer, adjust the spray conditions (in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com