Low-carbon environmentally-friendly water-based soldering flux

A low-carbon, environmentally friendly, flux technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of flammability and environmental protection of flux, and achieve the effect of reducing carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

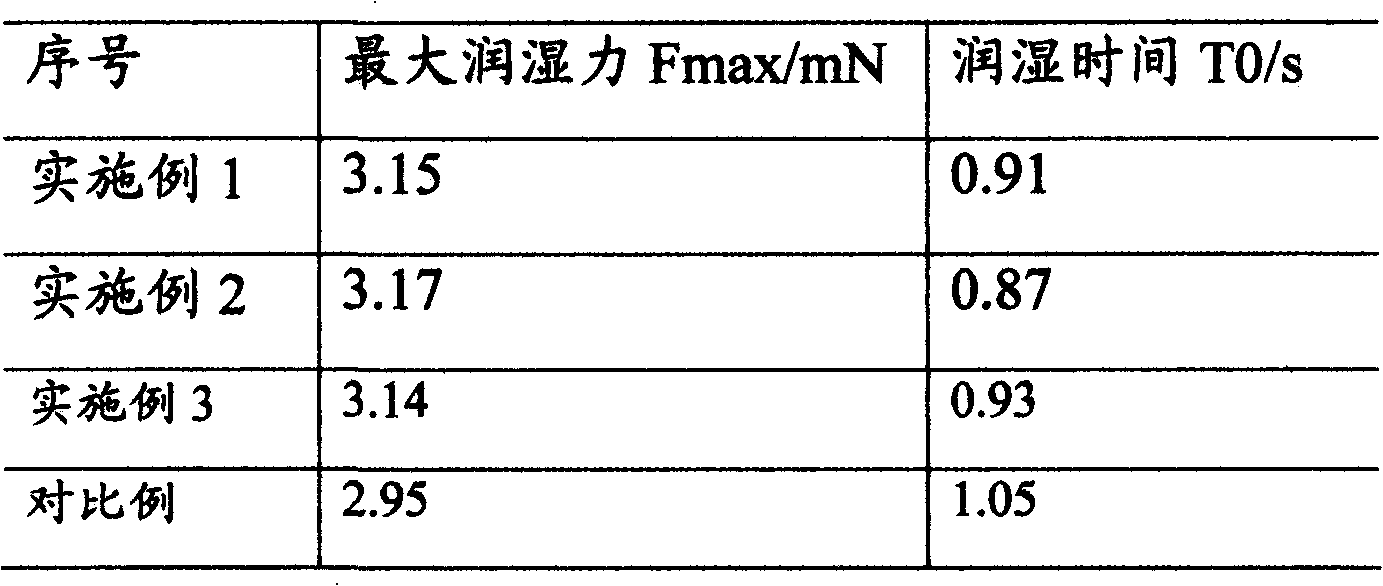

specific Embodiment 1

[0022] The composition of low-carbon environment-friendly water-based flux:

[0023] 94% deionized water

[0024] 1.8% C12 ethers

[0025] 3% Succinic Acid

[0026] 0.1% Hydroxymethylbenzotriazole

[0027] 0.1% N,N-Dimethyldodecylamine

[0028] 1% Surfactant YK-302

specific Embodiment 2

[0029] The composition of low-carbon environment-friendly water-based flux:

[0030] 85% deionized water

[0031] 5% PEG800

[0032] 4.2% C12 ethers

[0033] 4% malonic acid

[0034] 0.4% Hydroxymethylbenzotriazole

[0035] 0.4% N,N-Dimethyldodecylamine

[0036] 1% Surfactant YK-302

specific Embodiment 3

[0037] 95% deionized water

[0038] 1.1% C12 ethers

[0039] 3% Succinic Acid

[0040] 0.2% 2-ethylimidazole

[0041] 0.2% N,N-Dimethyldodecylamine

[0042] 0.5% Surfactant YK-302

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com