Low-temperature soft template one-step synthesis method for graphitized ordered mesoporous carbon material

A graphitization and mesoporous carbon technology, applied in the field of mesoporous materials, can solve the problems of unfavorable formation of mesoporous carbon materials with orderly structure, collapse of carbon material pore structure, complicated steps, etc., so as to reduce damage and reduce heat treatment. Effect of temperature, simplified synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

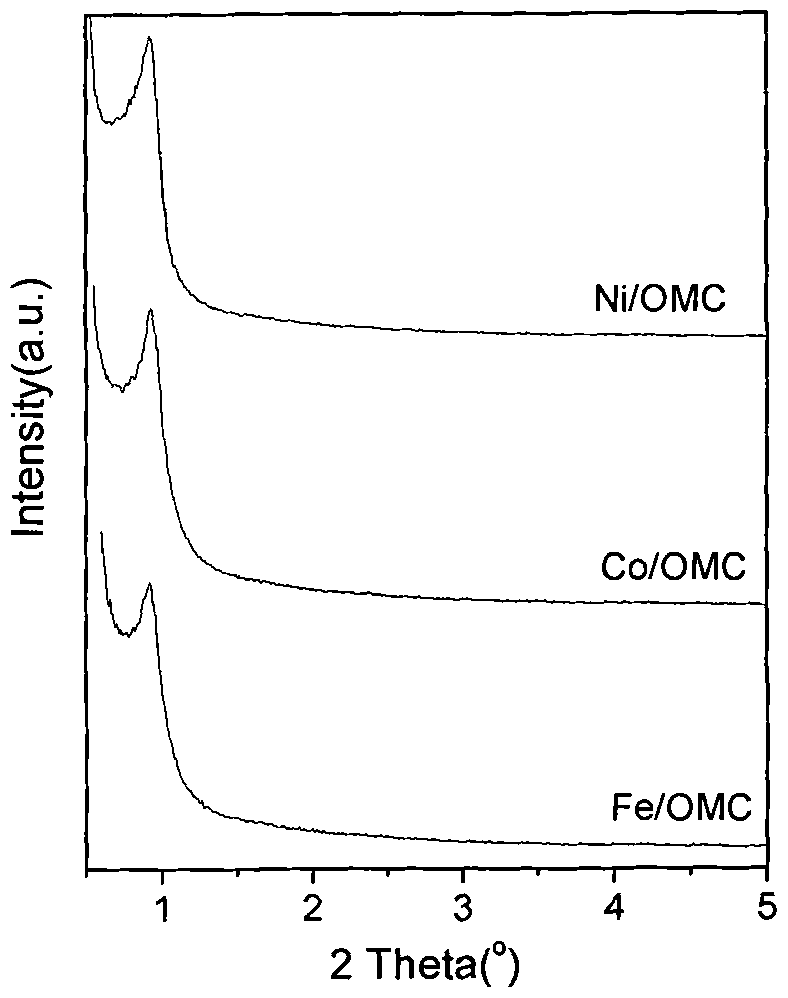

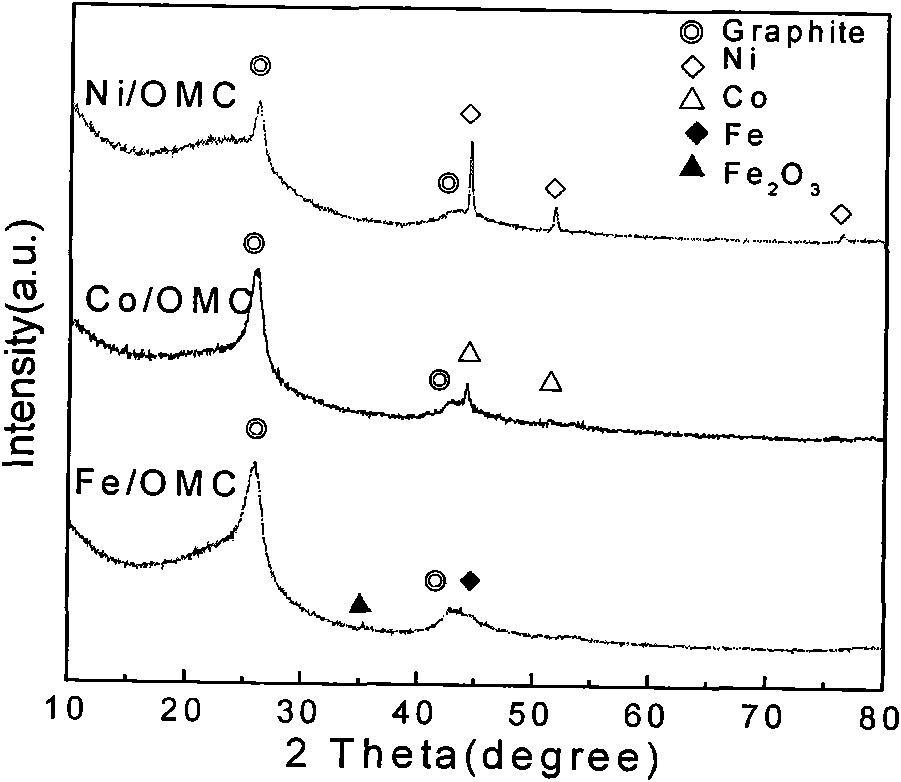

[0025] At room temperature, dissolve 2.5g F127 and 1.65g resorcinol in water / ethanol (volume ratio 1 / 1) solution, and magnetically stir for about 30 minutes until the solution turns bright brown. Add the pre-prepared water / ethanol mixed solution containing 0.872g Ni(NO3)2·6H2O into the mixed solution of F127 and hydroquinone, adjust the pH of the solution to about 1.7 with 1.0M HCl, stir and mix for 2 hours, the solution turns blue green. Then, 2.5 g of 37% formaldehyde solution was added dropwise into the above mixture, and stirring was continued for 2 hours. Place at room temperature for 72 hours, the mixed solution is gradually divided into upper and lower layers, the upper layer is a water and ethanol phase, the lower layer is a cobalt-containing phenolic resin-nonionic surfactant composite phase, the supernatant is discarded, and the lower nickel-containing organic phase is stirred for 12 hour, the resulting viscous sol was thermally polymerized at a low temperature of 8...

Embodiment 2

[0027] At room temperature, dissolve 2.5g of F127 and 1.65g of resorcinol in water / ethanol (volume ratio 1 / 1) and stir magnetically for about 30 minutes until the solution turns bright brown. Add the pre-prepared water / ethanol mixed solution containing 0.873g Co(NO3)2·6H2O into the mixed solution of F127 and hydroquinone, adjust the pH of the solution to about 1.7 with 1.0M HCl, stir and mix for 2 hours, the solution is light Fuchsia. Then, 2.5 g of 37% formaldehyde solution was added dropwise into the above mixture, and stirring was continued for 2 hours. Place at room temperature for 72 hours, the mixed solution is gradually divided into upper and lower layers, the upper layer is a water and ethanol phase, the lower layer is a cobalt-containing phenolic resin-nonionic surfactant composite phase, the supernatant is discarded, and the lower cobalt-containing organic phase is stirred for 12 hour, the resulting viscous sol was thermally polymerized at a low temperature of 85°C ...

Embodiment 3

[0029] At room temperature, dissolve 2.5g F127 and 1.65g resorcinol in water / ethanol (volume ratio 1 / 1) solution, and magnetically stir for about 30 minutes until the solution turns bright brown. Add the pre-prepared water / ethanol mixed solution containing 0.606g Fe(NO3)3·9H2O into the mixed solution of F127 and hydroquinone, stir and mix for 2 hours, and the solution turns dark purple. Then, 2.5 g of 37% formaldehyde solution was added dropwise into the above mixture, and stirring was continued for 2 hours. After standing at room temperature for 60 hours, the mixed solution was gradually divided into upper and lower layers, the upper layer was a water and ethanol phase, and the lower layer was an iron-containing phenolic resin-nonionic surfactant composite phase. The supernatant was discarded, and the lower iron-containing organic phase was stirred for 12 hour, the resulting viscous sol was thermally polymerized at a low temperature of 85°C for 12 hours, and the product was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com