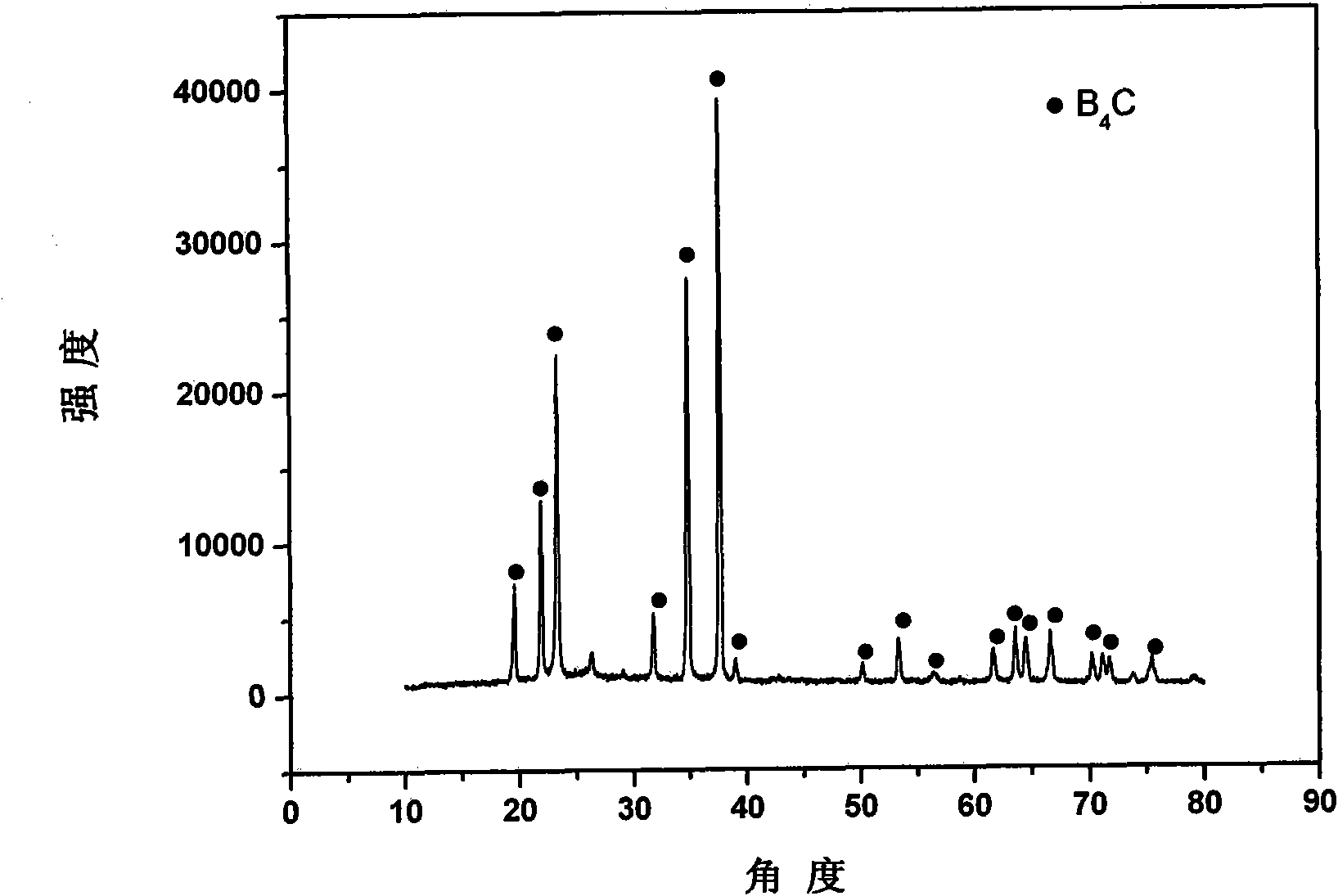

Preparation method for synthesizing boron carbide powder at low temperature

A boron carbide and powder technology, which is applied in the field of low-temperature synthesis and preparation of boron carbide powder, can solve the problems of high product purity, high cost, and difficulty in removing magnesium oxide, and achieves the effects of low preparation cost and low energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

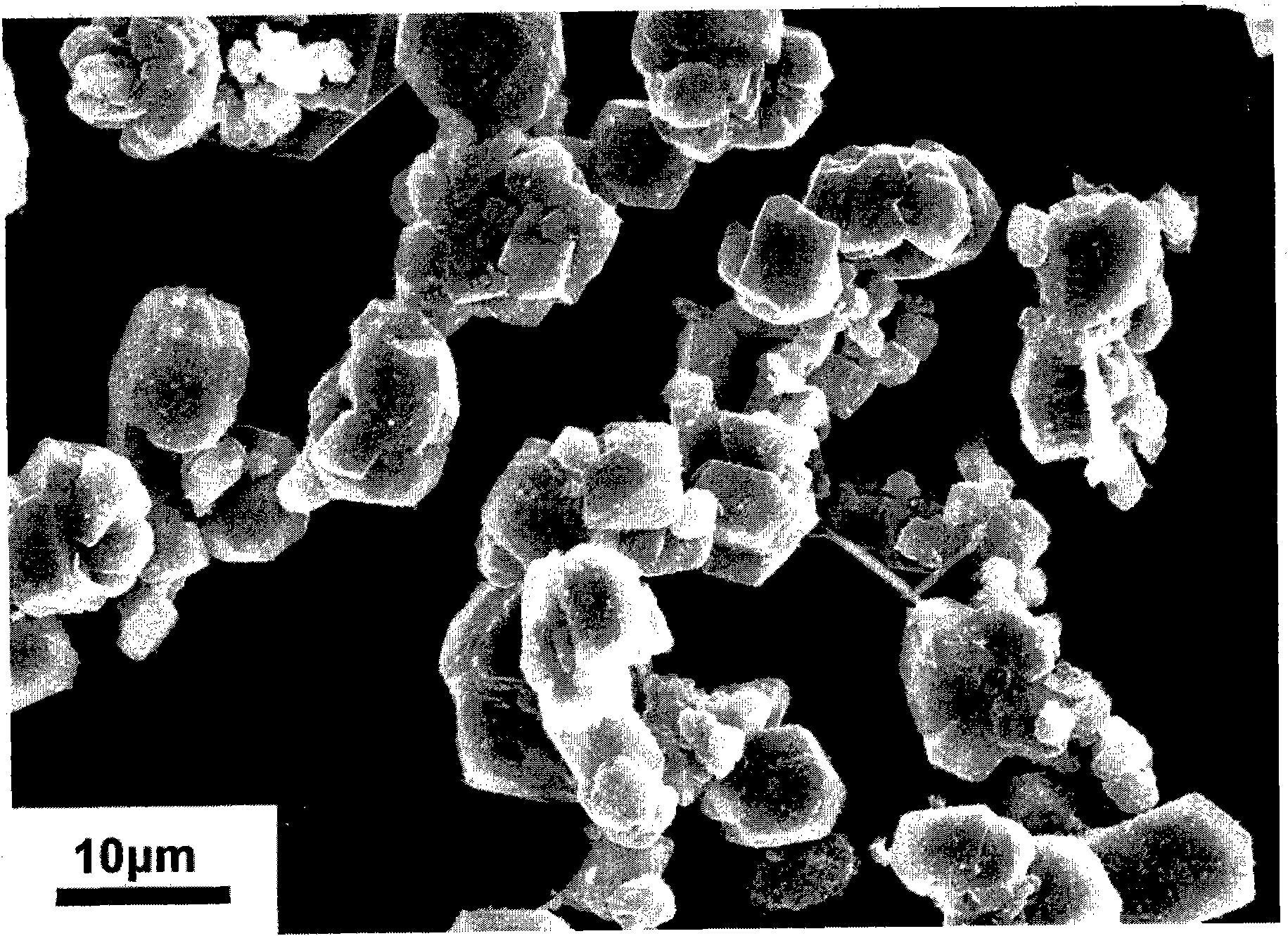

Embodiment 1

[0022] In this embodiment, 24 grams of boric acid are placed in a beaker, 20 milliliters of glycerol is added into the beaker and stirred evenly with a glass rod, the beaker with the liquid is placed in an ultrasonic cleaner, and the heating temperature is set to 85°C, working frequency 40kHz, ultrasonic power 100W, after ultrasonic oscillation for 20 minutes, boric acid is completely dissolved in glycerol and forms a transparent liquid, add 1.6 grams of 24 nanometer activated carbon powder to the transparent liquid, and continue to ultrasonic Shake for 15 minutes to make a uniform mixed liquid.

[0023] The mixed liquid was transferred to a crucible, and the crucible was put into a tube furnace to be heated in air at a heating temperature of 550° C., a holding time of 0.5 hour, and a heating rate of 5° C. / min.

[0024] The product obtained after heating was ground with an agate mortar to form particles with a particle size of less than 1 mm.

[0025] The particles are put in...

Embodiment 2

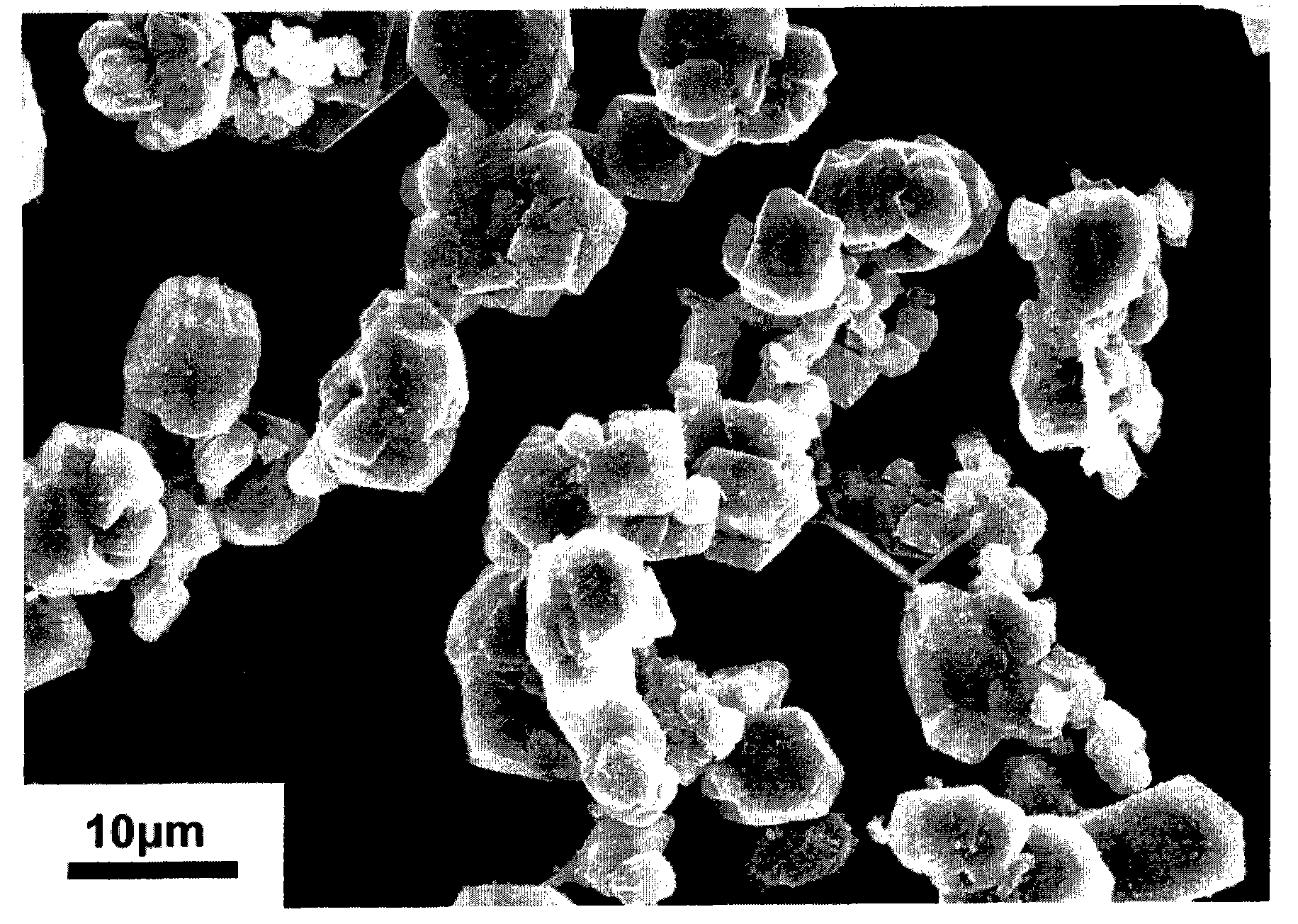

[0030] In this embodiment, 16 grams of boric acid are placed in a beaker, 10 milliliters of glycerol is added into the beaker and stirred evenly with a glass rod, the beaker of the liquid is placed in an ultrasonic cleaner, and the heating temperature is set to 95°C, working frequency 40kHz, ultrasonic power 90W, after ultrasonic oscillation for 30 minutes, boric acid is completely dissolved in glycerol and forms a transparent liquid, add 1.6 grams of 24 nanometer activated carbon powder to the transparent liquid, and continue to ultrasonic Shake for 30 minutes to make a uniform mixed liquid.

[0031] The mixed liquid was transferred to a crucible, and the crucible was put into a tube furnace to be heated in air at a heating temperature of 450° C., a holding time of 2 hours, and a heating rate of 5° C. / min.

[0032] The product obtained after heating was ground with an agate mortar to form particles with a particle size of less than 1 mm.

[0033] The particles are put into a...

Embodiment 3

[0038] In this embodiment, 24 grams of boric acid are placed in a beaker, 30 milliliters of glycerol is added into the beaker and stirred evenly with a glass rod, the beaker with the liquid is placed in an ultrasonic cleaner, and the heating temperature is set to 75°C, working frequency 40kHz, ultrasonic power 80W, after 15 minutes of ultrasonic oscillation, the boric acid is completely dissolved in glycerol and forms a transparent liquid, add 1.2 grams of 24 nanometer activated carbon powder to the transparent liquid, and continue to ultrasonic Shake for 10 minutes to make a homogeneous mixed liquid.

[0039] The mixed liquid was transferred to a crucible, and the crucible was put into a tube furnace to be heated in air at a heating temperature of 650° C., a holding time of 3 hours, and a heating rate of 8° C. / min.

[0040] The product obtained after heating was ground with an agate mortar to form particles with a particle size of less than 1 mm.

[0041] The particles are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com