In-situ activation modification treatment method for suspended filter material

A suspension filter material and treatment method technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult control of operating conditions, long treatment time, complex process structure, etc. , to achieve the effect of reducing equipment footprint and investment, reducing dosing, and simple operation control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

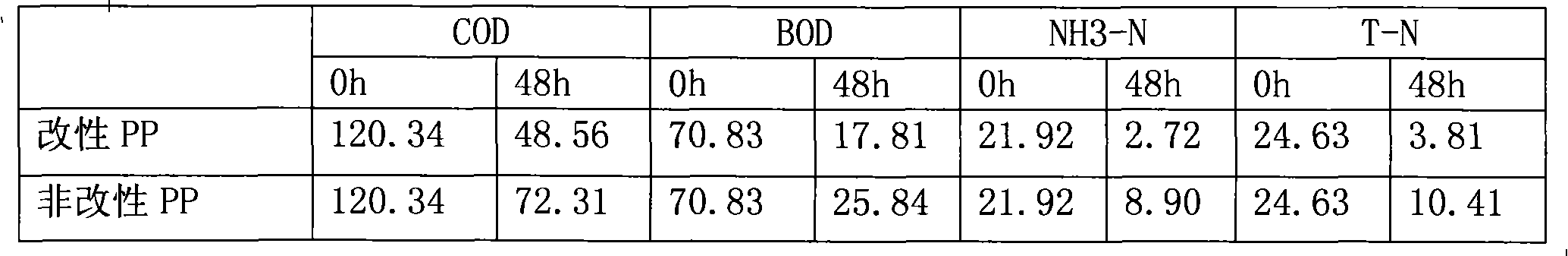

Embodiment 1

[0028] 1. Put 55 parts of rough porous foamed PP foamed plastic particles into 45 parts of activation solution, stir for 24 hours at a speed of 80 rpm, and soak for 2 days; The activation solution is immobilized on the surface and inside of the foamed plastic particles;

[0029] 2. Take out the suspended filter material from the activation solution, and let it dry naturally in a ventilated and dark place.

[0030] Wherein, the bioactivator is processed by the following method:

[0031] 1) Mix 8 parts of pig liver with 15 parts of wheat flour and 5 parts of alcohol-fermented yeast, and then add 8 parts of glucose to prepare;

[0032] 2) Ferment at room temperature at 30°C and puff for 20 hours to obtain puffed products;

[0033] 3) Add half of the amount of wheat flour, alcohol-fermenting yeast and glucose in step 1) to the puffed product, that is, 7.5 parts of wheat flour, 2.5 parts of alcohol-fermenting yeast and 4 parts of glucose for repeated fermentation for 48 hours to ...

Embodiment 2

[0039] 1. Put 70 parts of rough porous foamed PP foamed plastic particles into 65 parts of activation solution, stir for 30 hours at a speed of 100 rpm, and soak for 3 days; The activation solution is immobilized on the surface and inside of the foamed plastic particles;

[0040] 2. Take out the suspended filter material from the activation solution, and let it dry naturally in a ventilated and dark place.

[0041] Wherein, the bioactivator is processed by the following method:

[0042] 1) Mix 10 parts of pig pancreas with 20 parts of sorghum flour and 10 parts of baker's yeast, and then add 10 parts of skim milk to prepare;

[0043] 2) ferment the mixture obtained in step 1) at room temperature at 40°C, and puff it for 24 hours to obtain puffed products;

[0044] 3) Add half of the amount of wheat flour, baker's yeast and glucose in step 1) to the puffed product, that is, 10 parts of sorghum flour, 5 parts of baker's yeast and 5 parts of skim milk, and repeat fermentation f...

Embodiment 3

[0051] 1. Put 35 parts of rough porous foamed PP foamed plastic particles into 25 parts of activation solution, stir for 22 hours at a speed of 65 rpm, and soak for 1.5 days; The activation solution is immobilized on the surface and inside of the foamed plastic particles;

[0052] 2. Take out the suspended filter material from the activation solution, and let it dry naturally in a ventilated and dark place.

[0053] Wherein, the bioactivator is processed by the following method:

[0054] 1) Mix 3 parts of pig's pancreas with 5 parts of flour mixture and 5 parts of baker's yeast, and then add 3 parts of skim milk; the flour mixture is made by mixing 3 parts of wheat flour and 2 parts of sorghum flour.

[0055] 2) ferment the mixture obtained in step 1) at room temperature at 22°C, and puff it for 18 hours to obtain puffed products;

[0056] 3) Add half of the flour mixture, baker's yeast and glucose in step 1) to the puffed product, that is, 2.5 parts of the flour mixture, 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com