Microwave-assisted immobilization method of aldolase

An aldolase, microwave technology, applied in microorganism-based methods, biochemical equipment and methods, immobilized on or in inorganic carriers, etc., can solve the problem of poor stability, high cost of kit carriers, and process details are not disclosed. and other problems to achieve the effect of improving temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of aldolase free enzyme:

[0045] Take the recombinant strain E.Coil BL21 / pET 303CT / DERA thermo bacteria in our research group, that is, the SEQ ID NO 1 in the Chinese Patent Publication No. CN 101565697A, in the LB liquid medium (Oxoid LTD) of 100ug / ml ampicillin (sigma) ., Basingstoke, Hampshire, England) were cultivated at 37°C for 20 hours to obtain a seed liquid, and 10ml of the seed liquid was added to LB liquid medium of 1L 100ug / ml ampicillin and expanded at 37°C until the bacterial liquid Add the inducer IPTG when the OD600 reaches 0.6, and make the final concentration of the inducer IPTG 0.5mM, and then induce at 30C for 4 hours, collect the bacteria by centrifugation, break the cells of the bacteria, and purify the protein with a nickel column to obtain aldehyde Aldolase free enzyme, measuring enzyme concentration, the aldolase free enzyme is preserved with PH6.5, concentration is the sodium phosphate buffer of 0.01M, and the free enzyme of measur...

Embodiment 2

[0047] Aldolase free enzyme made into immobilized aldolase:

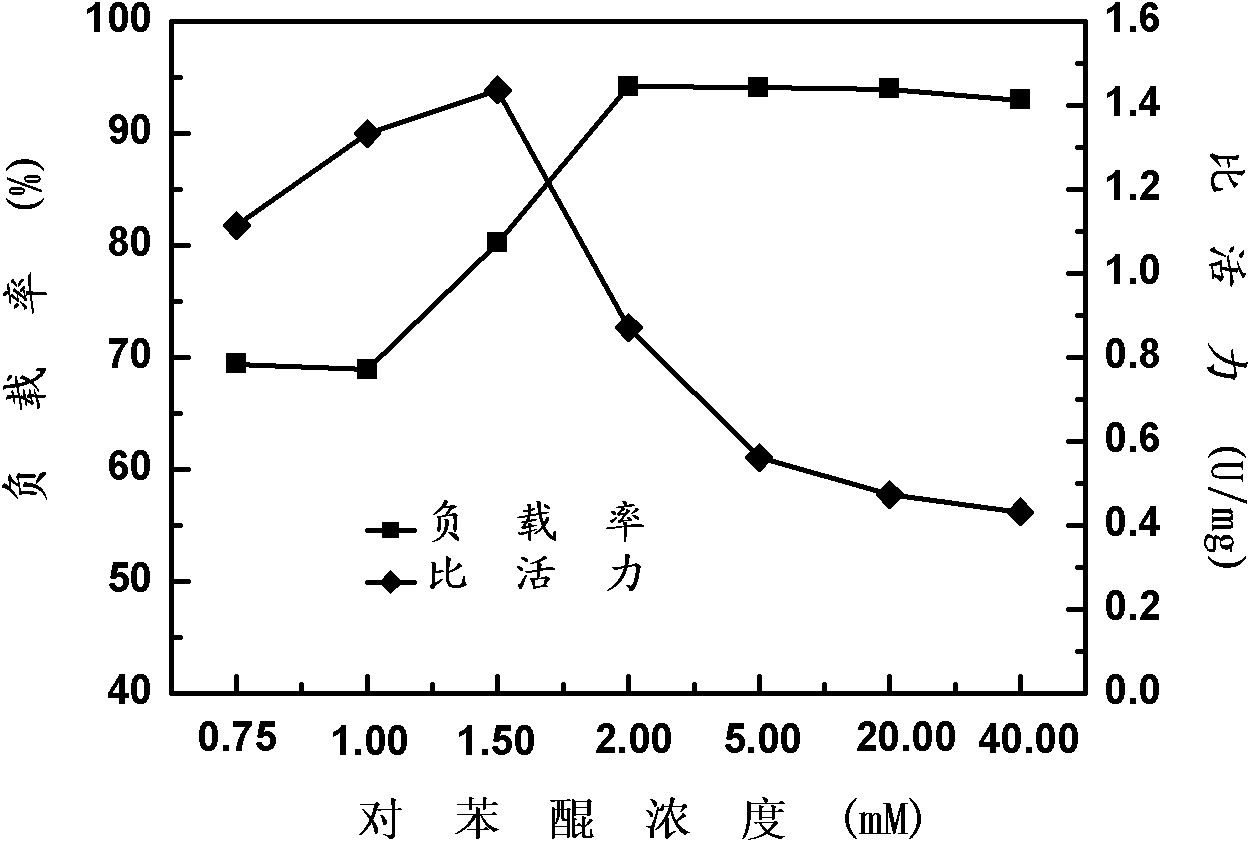

[0048] (1) Activate the carrier: select 3ml of p-benzoquinone solution so that the final concentration in the reaction solution is 1.5mM and 20mg of MCFs-NH 2 Shake at 150rpm in a constant temperature water bath shaker at 20°C for 2 hours, centrifuge, wash the precipitate with pH 7.0, 0.01M PBS solution, and redisperse the washed precipitate in 2.445mL of pH 8.0, 0.1M PBS In the solution, because the solid-liquid separation is realized during the centrifugation process, it is considered that the weight of the carrier remains unchanged, which is still 20 mg.

[0049] (2) get the activated carrier liquid 2.445ml that step (1) obtains, then add the aldolase free enzyme sodium phosphate buffer 0.55mL of the 1.8mg / ml that embodiment 1 obtains according to the mass ratio of 50mg enzyme / g carrier, Mix evenly to obtain a mixture;

[0050] (3) Take the mixed solution of step (2) and vibrate for 20 hours under the condition...

Embodiment 3

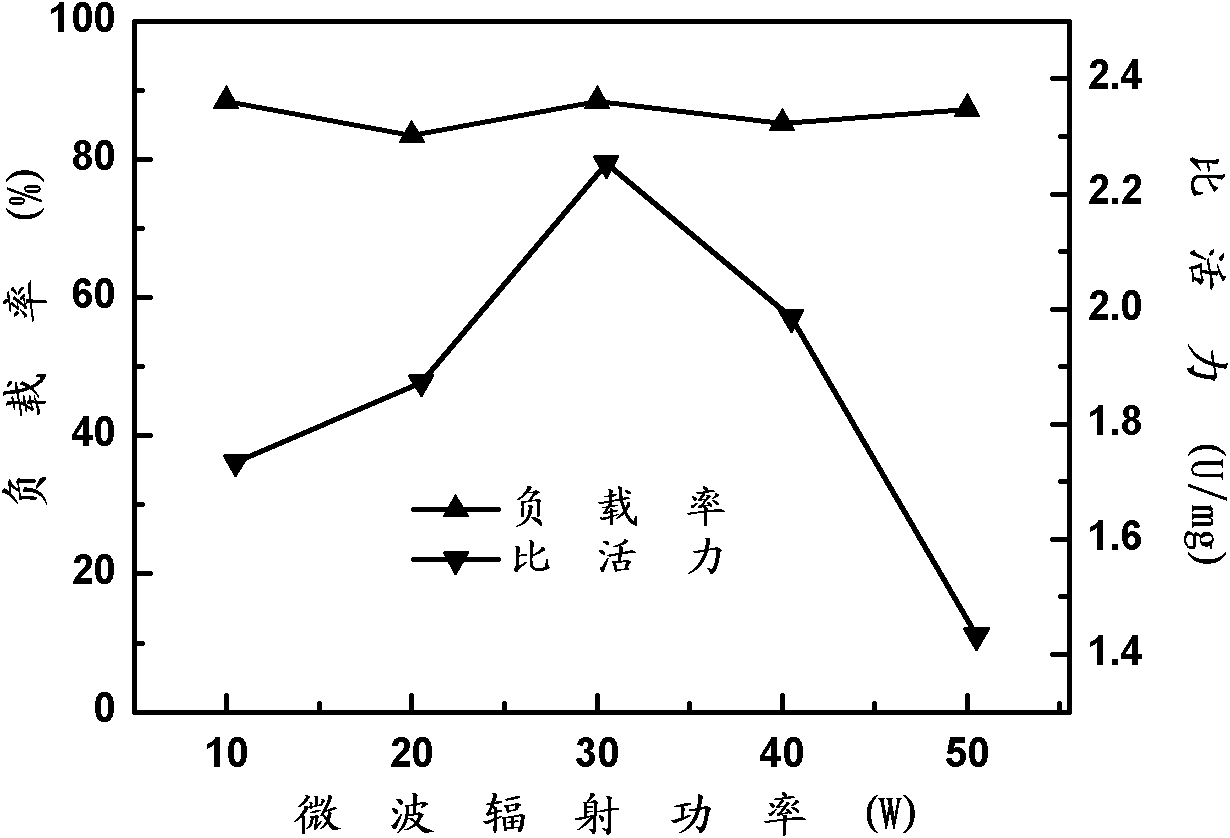

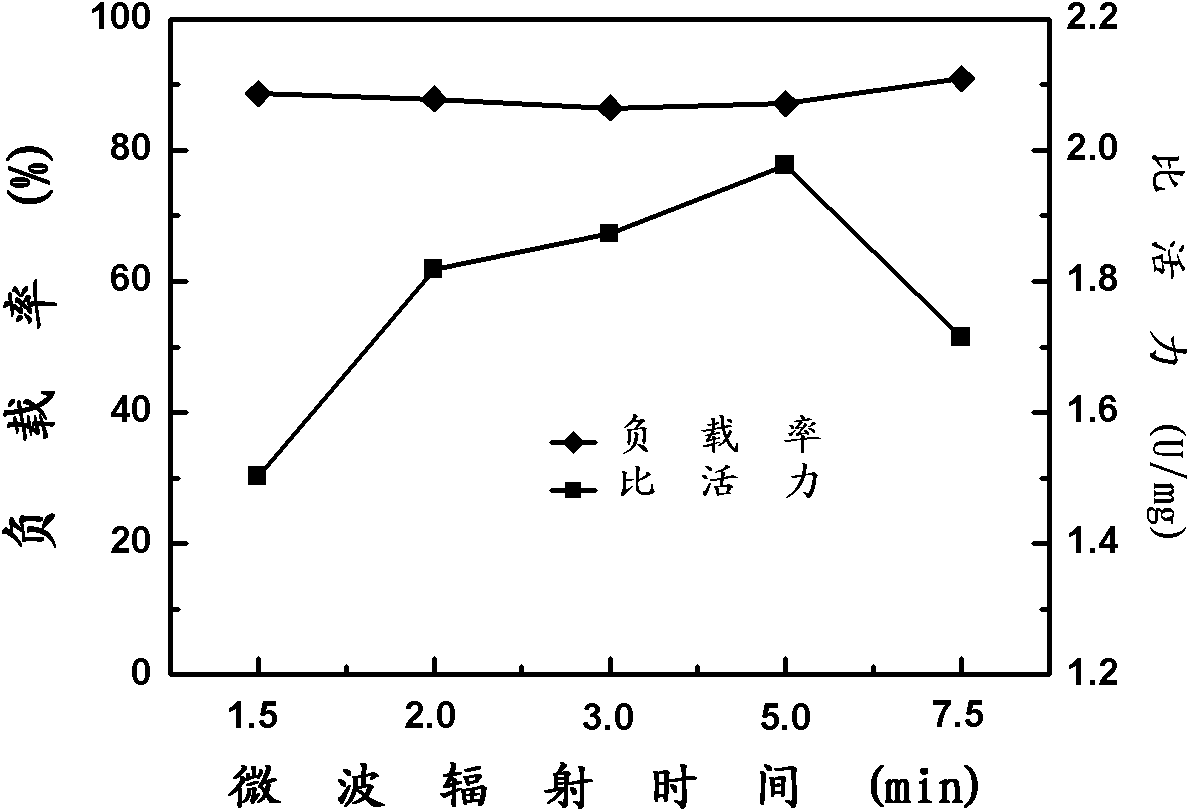

[0052] Prepare aldolase free enzyme into immobilized aldolase by microwave method:

[0053] (1) Activate the carrier: select 3ml of p-benzoquinone solution to make the final concentration of 1.5mM and 20mg MCFs-NH 2 Shake at 150rpm in a constant temperature water bath shaker at 20°C for 2 hours, centrifuge, take the precipitate and wash it with a pH 7.0, 0.01M PBS solution, and redisperse the washed precipitate in 2.445mL of a pH 8.0, 0.1M PBS solution Among them, because the solid-liquid separation is achieved during the centrifugation process, the weight of the carrier is considered to remain unchanged, which is still 20 mg.

[0054] (2) In the carrier mixed solution of the activation that step (1) obtains, according to the mass ratio of 50mg enzyme / g carrier, add the aldolase free enzyme sodium phosphate buffer solution 0.55mLml of 1.8mg / ml that embodiment 1 obtains , and mix well to obtain a mixture.

[0055] (3) The mixture in step (2) was irradiated for 1.5 minutes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com