Method for preparing aluminum-based in-situ composite materials at low temperature in presence of catalysts

An in-situ composite material and low-temperature catalysis technology, which is applied in the field of low-temperature catalysis preparation, can solve the problems of deepening the harm of fluoride salts to the human body and the environment, affecting the particle yield, reducing the reaction temperature, etc. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: TiB 2 Low-temperature catalytic preparation of carbon nanotubes for particle-reinforced aluminum matrix composites

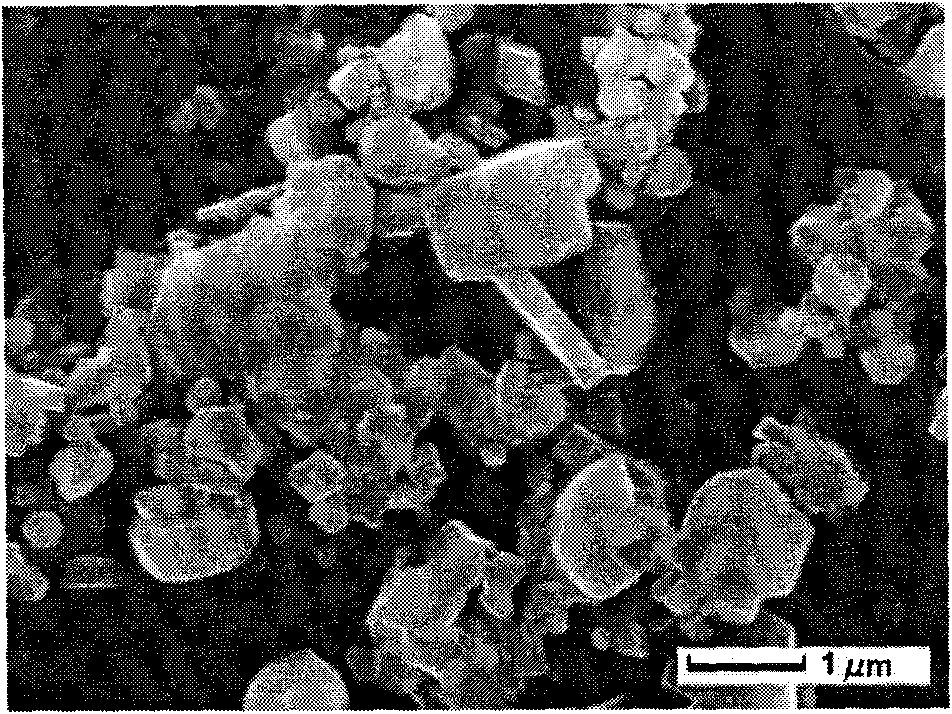

[0033] Potassium fluorotitanate K 2 TiF 6 and potassium fluoroborate KBF 4 As a reactive salt, TiB was prepared by the mixed salt reaction method 2 Particle reinforced aluminum matrix composites. Use a bell jar to add the preheated mixed salt powder into the high-temperature melt in batches, and stir thoroughly to ensure that the powder is fully in contact with the melt. When no catalyst is added, the optimized synthesis temperature is 870-900°C, the suitable reaction time is 25-30min, and the prepared composite structure is as follows: figure 1 shown.

[0034] The carbon nanotubes with 1.2wt.% of the salt mass are mixed into the mixed salt. Then the in-situ reaction can be completed at 820-830°C, and the reaction time can be shortened to 10-15min. The prepared composite structure is as follows: figure 2 shown, with figure 1 Organi...

Embodiment 2

[0036] Example 2 ZrB 2 Low-temperature Catalytic Preparation of Artificial Graphite for Particle Reinforced Aluminum Matrix Composites

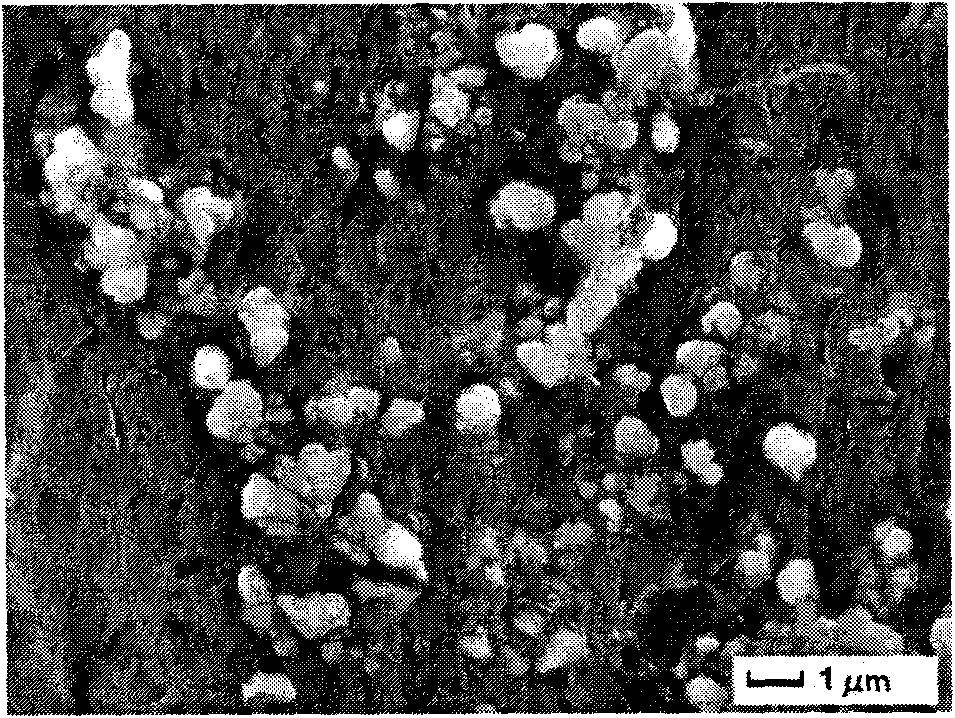

[0037] Potassium fluozirconate K 2 ZrF 6 and potassium fluoroborate KBF 4 As a reactive salt, ZrB was prepared by the mixed salt reaction method 2Particle reinforced aluminum matrix composites. Use a bell jar to add the preheated mixed salt powder into the high-temperature melt in batches, and stir thoroughly to ensure that the powder is fully in contact with the melt. When no catalyst is added, the optimized synthesis temperature is 880-900°C, the suitable reaction time is 20-25min, and the prepared composite structure is as follows: image 3 shown.

[0038] Add the artificial graphite powder of salt quality 2wt.% in mixed salt. Then the in-situ reaction can be completed at 830-840°C, the reaction time can be shortened to 10min, and the prepared composite structure is as follows: Figure 4 shown, with image 3 Organizations did not ...

Embodiment 3

[0040] Example 3 ZrB 2 Cryolite Catalytic Preparation of Particle Reinforced Aluminum Matrix Composites at Low Temperature

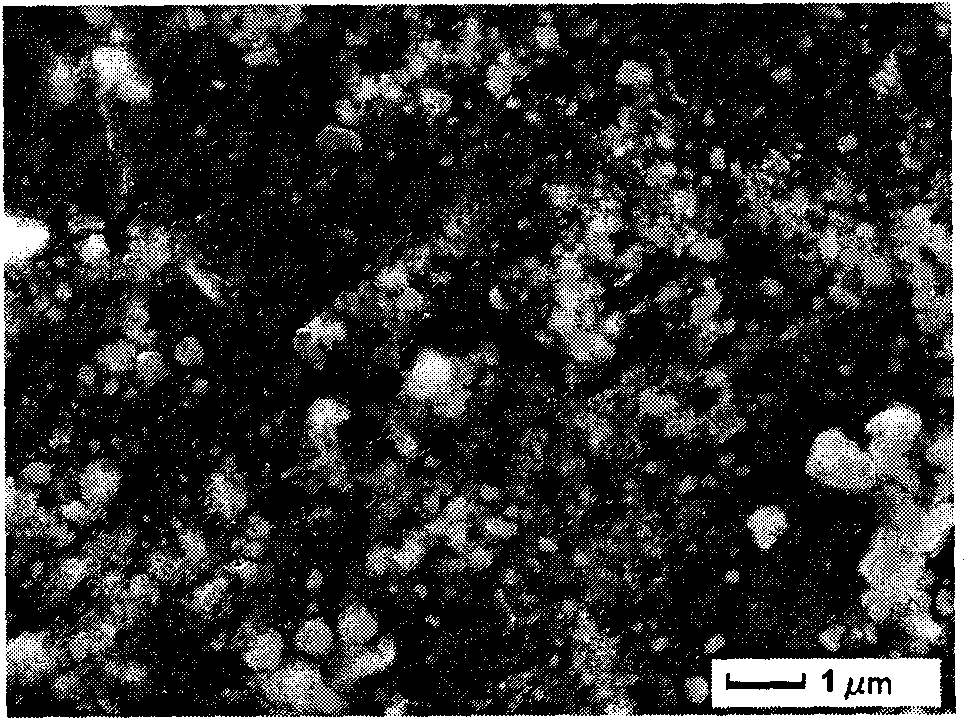

[0041] Potassium fluozirconate K 2 ZrF 6 and potassium fluoroborate KBF 4 As a reactive salt, ZrB was prepared by the mixed salt reaction method 2 Particle reinforced aluminum matrix composites. Use a bell jar to add the preheated mixed salt powder into the high-temperature melt in batches, and stir thoroughly to ensure that the powder is fully in contact with the melt. When no catalyst is added, the optimized synthesis temperature is 880-900°C, the suitable reaction time is 20-25min, and the prepared composite structure is as follows: image 3 shown.

[0042] The mixed salt is mixed with 3wt.% aluminum-magnesium spinel of the salt mass. Then the in-situ reaction can be completed at 830°C, and the reaction time can be shortened to 10 minutes. The prepared composite structure is as follows: Figure 5 shown, with image 3 Organizations did not dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com