Semiconductor device manufacturing method, semiconductor device, electronic device, semiconductor manufacturing apparatus and storage medium

A manufacturing method and a technology for manufacturing a device, which are applied in the field of storage media and can solve problems such as increased wiring resistance and lack of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

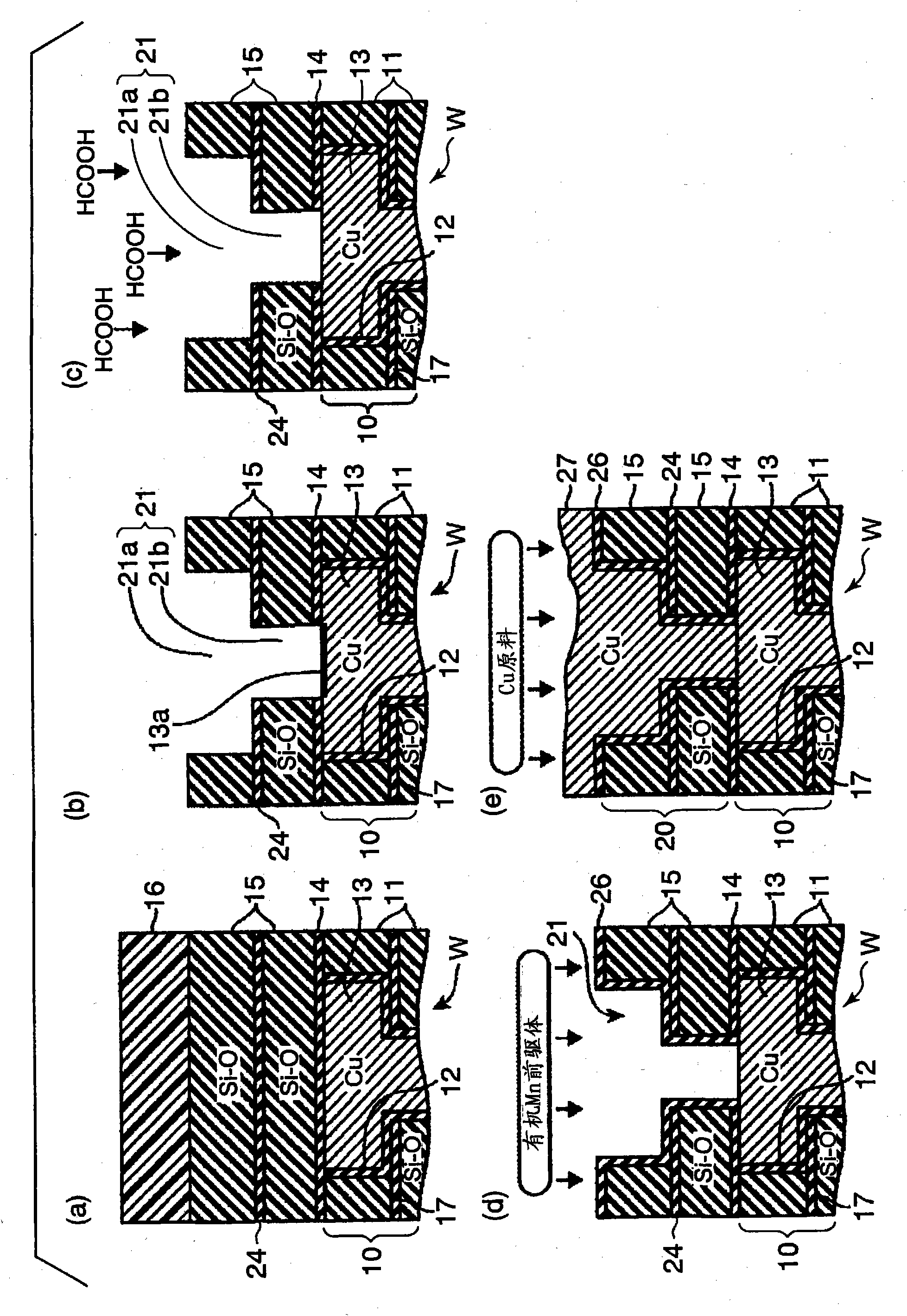

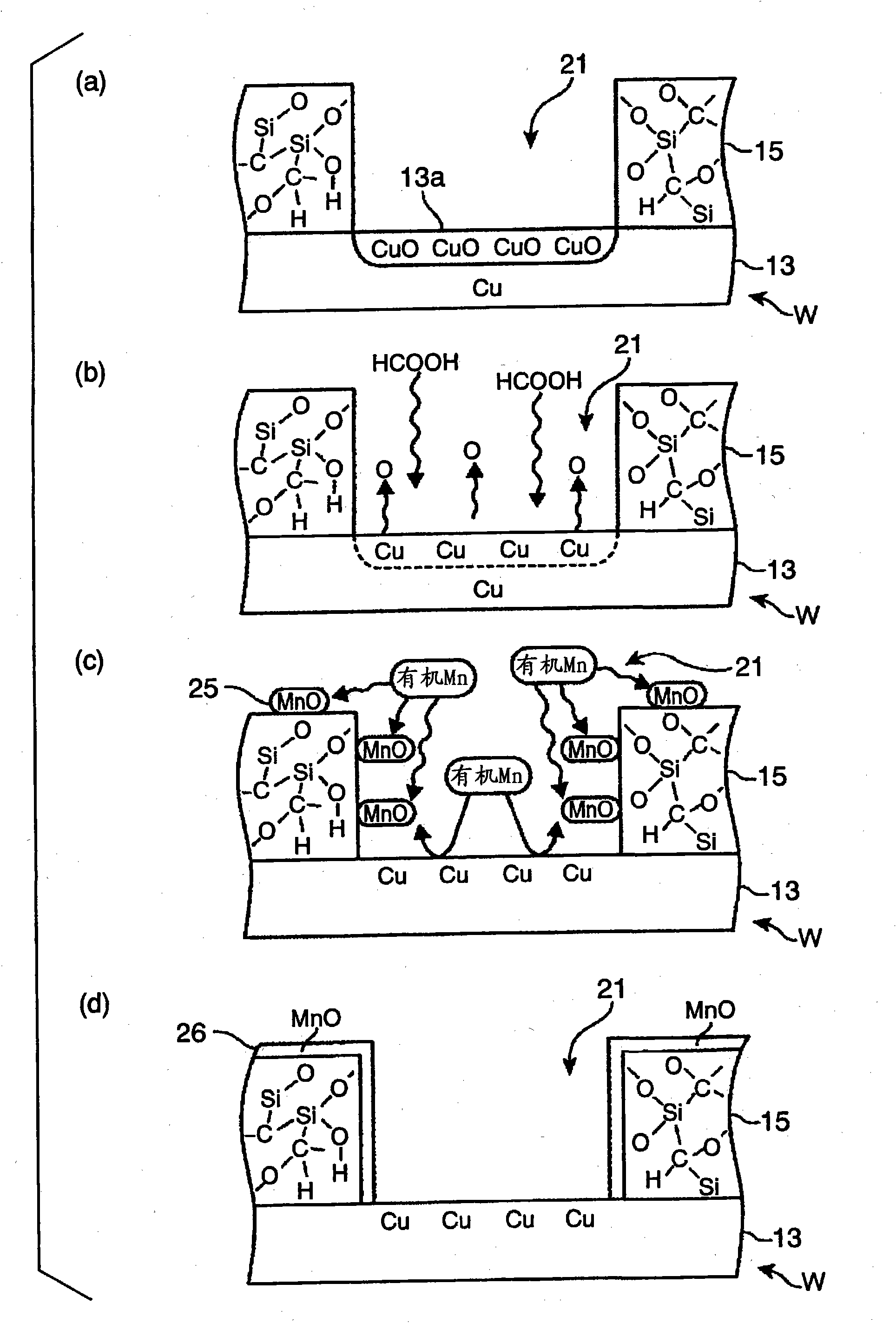

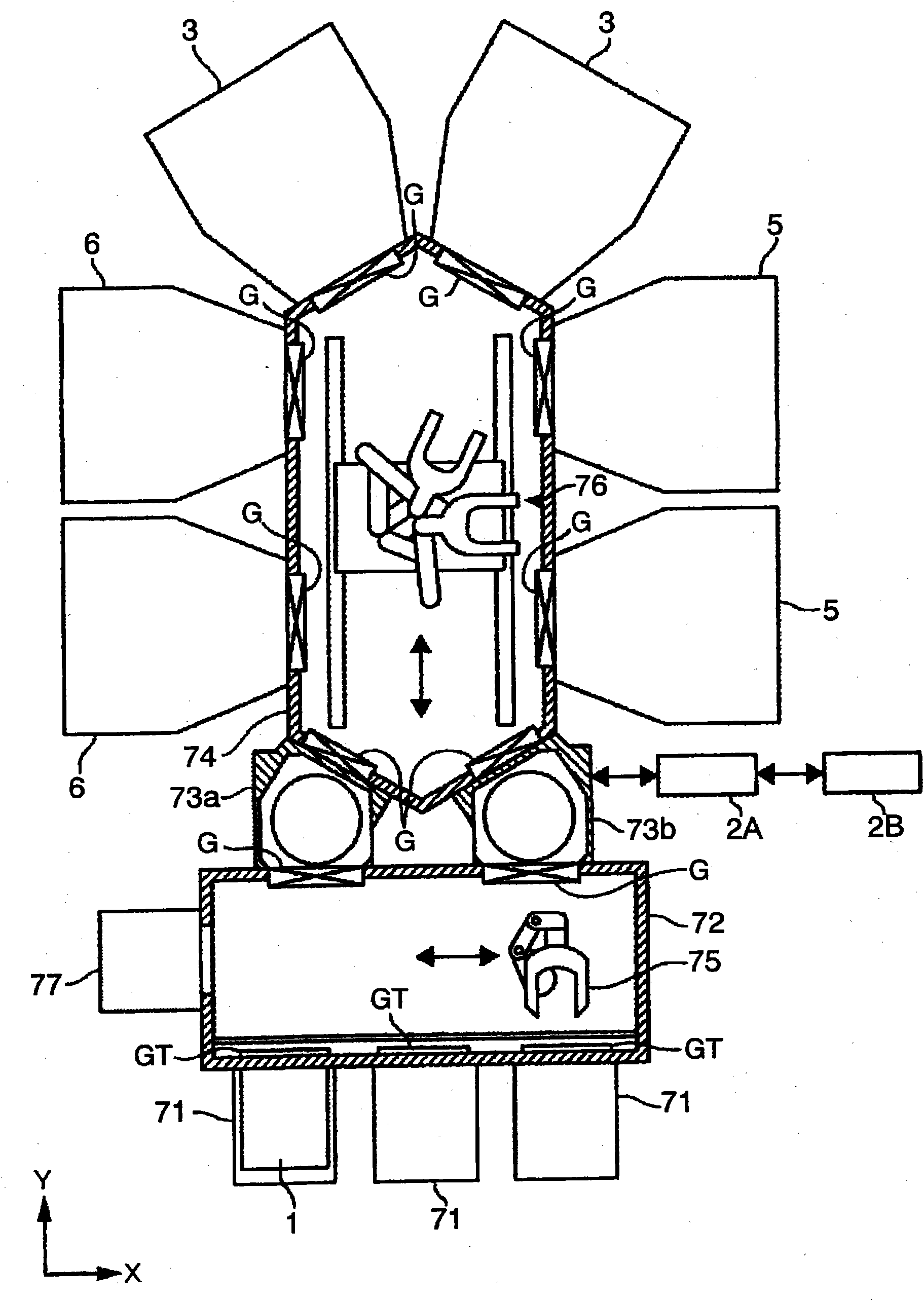

Examples

Embodiment

[0154] Next, experiments performed on the present invention will be described. In the experiment, used Figure 8 (a) Wafer W for testing is shown. This wafer W was produced as follows. First, a film was formed on a silicon substrate 90 by a plasma CVD method using TEOS (Tetra Ethoxy Silane, alias Tetraethyl Orthosilicate) at 350° C. to obtain a silicon oxide film 91 with a film thickness of 100 nm. Then, on this silicon oxide film 91, a manganese oxide layer 92 is formed in the Cu-MnOxCVD module 5 described above under the following film formation conditions. In addition, on the surface of the wafer W, a copper film 93 was formed by a sputtering method so as to have a film thickness of 100 nm. Thereafter, the wafer W was heat-treated under the following annealing conditions in order to confirm the presence or absence of copper diffusion. Thereafter, the experiments described below were performed on the wafer W. Also, since this experiment does not require good step covera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com