Titanium-based multi-metal oxide catalyst for removing diesel engine NOx by NH3-SCR in wide temperature window

A technology of NH3-SCR and multiple metals, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of narrow activation temperature window and poor selectivity, Achieve the effects of enhancing oxygen recovery performance, improving high temperature activity, and reducing NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

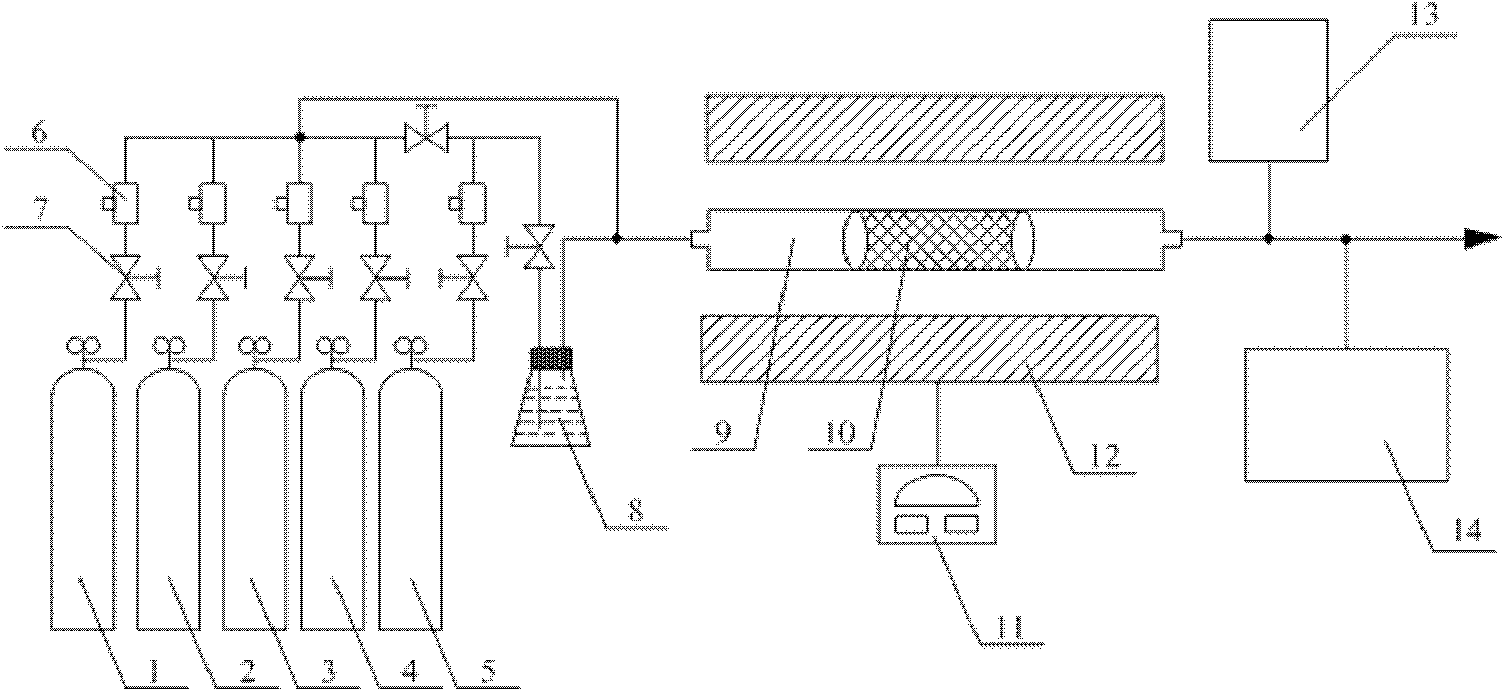

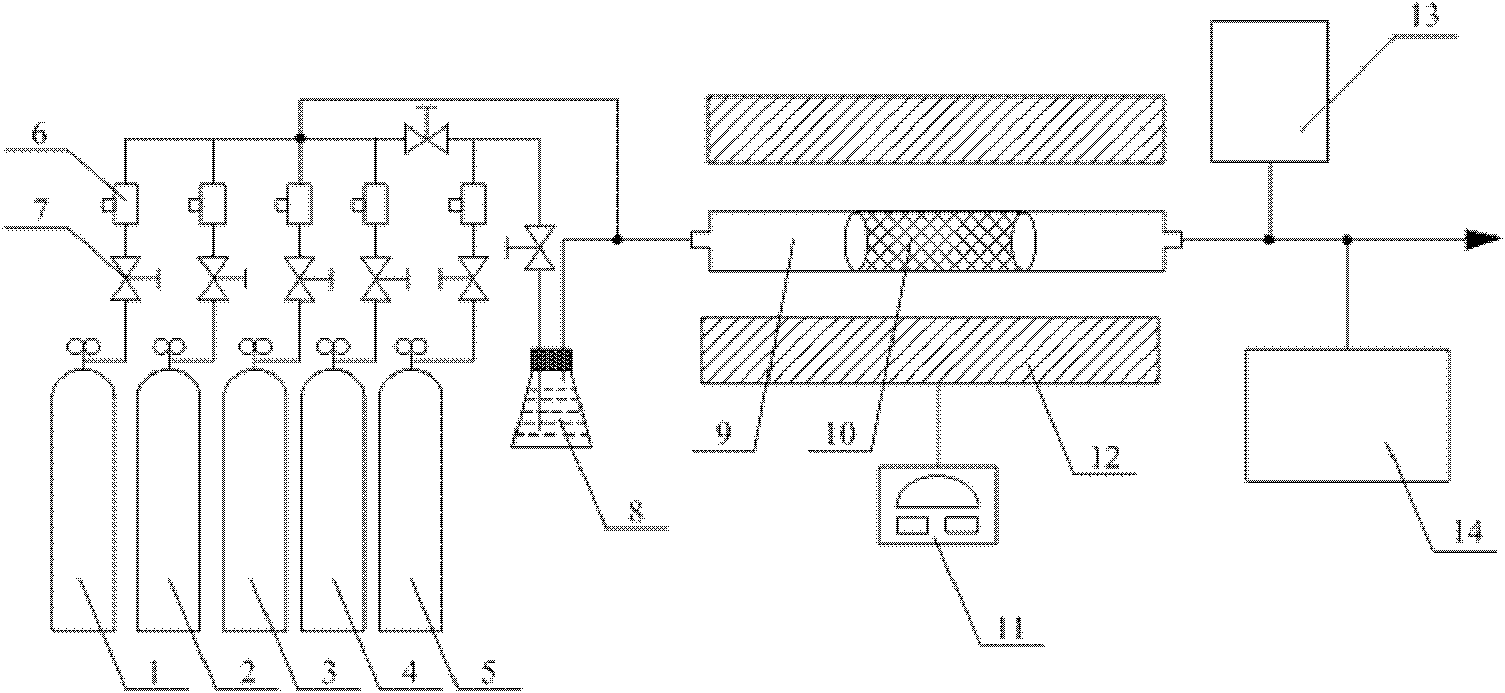

Method used

Image

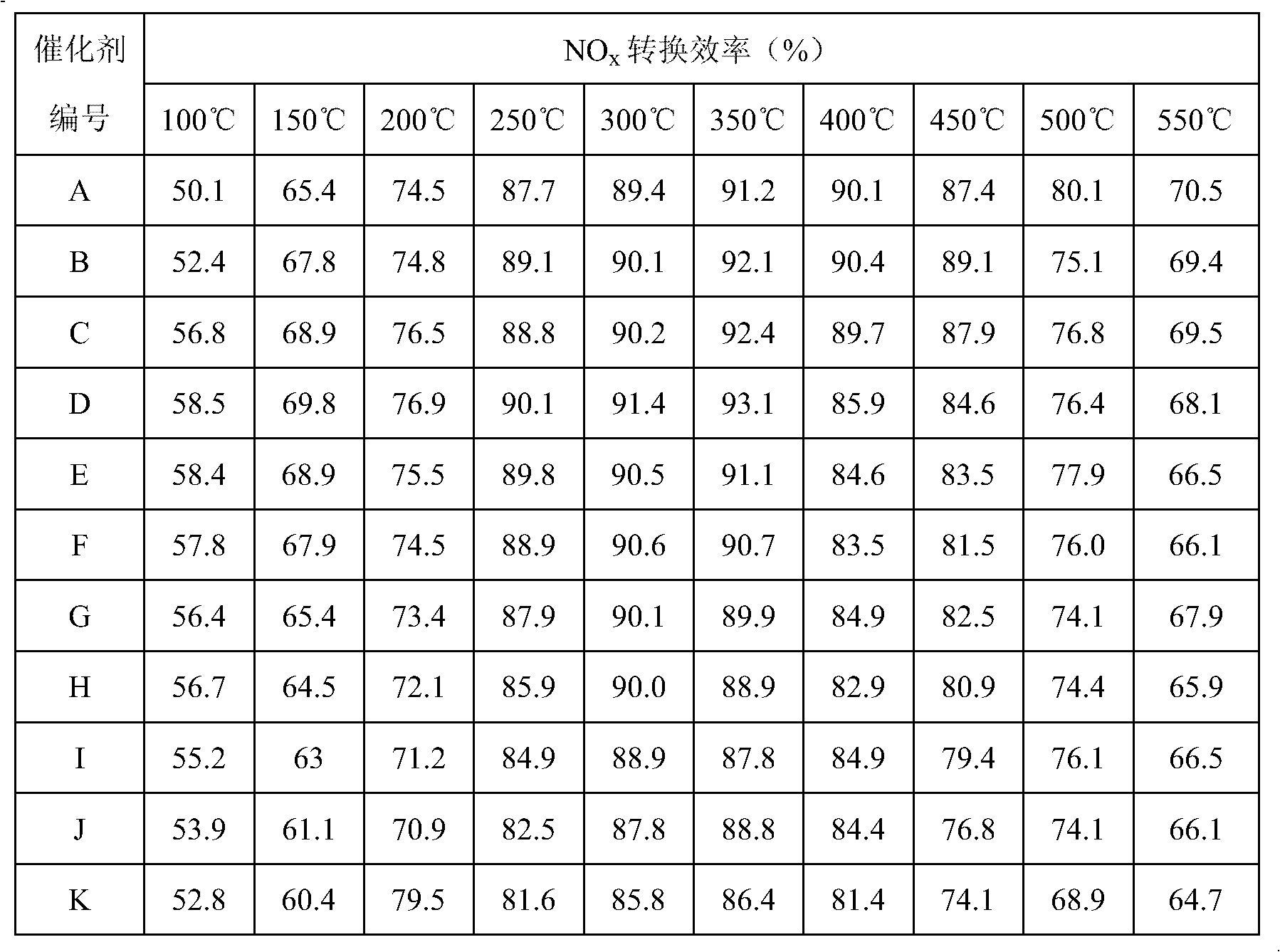

Examples

Embodiment 1

[0034] (1) TiO 2 preactivation process

[0035] Nano TiO 2 Mix with water, heat at 60°C for 24h, heat and activate at 120°C for 72h, grind and tablet, and screen out 60-100 mesh activated TiO 2 Particles;

[0036] (2) Determination of the main active components of metal oxides and the loading of co-catalysts

[0037] Follow V 2 o 5 : CeO 2 :MnO 2 : Fe 2 o 3 : WO 3 : MoO 3 :TiO 2 =1: 2: 5: 2: 3: 5: 82 mass ratio calculates and obtains the consumption of catalyst loading medicine to be respectively: ammonium metavanadate 0.643g, cerium nitrate 2.523g, manganese acetate 7.048g, ferric nitrate 1.262g, tungsten Ammonium Acid 1.64g, Ammonium Molybdate 3.066g, Nano TiO 2 41g.

[0038] (3) WO 3 、MoO 3 cocatalyst and V 2 o 5 , CeO 2 , MnO 2 , Fe 2 o 3 Loading of main active ingredient

[0039]Weigh 1.64g ammonium tungstate and dissolve it in 307ml deionized water; then weigh 3.066g ammonium molybdate and dissolve it in 1000ml deionized water; weigh 2.5g polyviny...

Embodiment 2

[0041] (1) TiO 2 preactivation process

[0042] Nano TiO 2 Mix with water, heat at 60°C for 24h, heat and activate at 120°C for 72h, grind and tablet, and screen out 60-100 mesh activated TiO 2 particle.

[0043] (2) Determination of the main active components of metal oxides and the loading of co-catalysts

[0044] Follow V 2 o 5 : CeO 2 :MnO 2 : Fe 2 o 3 : WO 3 : MoO 3 :TiO 2 = 1.5: 3: 5: 2: 3: 5: 80.5 The mass ratio calculated to obtain the consumption of catalyst loaded medicine is respectively: ammonium metavanadate 0.965g, cerium nitrate 3.785g, manganese acetate 2.819g, ferric nitrate 1.262g, tungsten Ammonium Acid 1.64g, Ammonium Molybdate 3.066g, Nano TiO 2 40.25g.

[0045] (3) WO 3 、MoO 3 cocatalyst and V 2 o 5 , CeO 2 , MnO 2 , Fe 2 o 3 Loading of main active ingredient

[0046] Weigh 1.64g ammonium tungstate and dissolve it in 307ml deionized water; then weigh 3.066g ammonium molybdate and dissolve it in 1000ml deionized water; weigh 2.5g po...

Embodiment 3

[0048] (1) TiO 2 preactivation process

[0049] Nano TiO 2 Mix with water, heat at 60°C for 24h, heat and activate at 120°C for 72h, grind and tablet, and screen out 60-100 mesh activated TiO 2 particle.

[0050] (2) Determination of the main active components of metal oxides and the loading of co-catalysts

[0051] Follow V 2 o 5 : CeO 2 :MnO 2 : Fe 2 o 3 : WO 3 : MoO 3 :TiO 2 =1: 4: 5: 2: 3: 5: 80 mass ratio calculates and obtains the consumption of catalyst loading medicine to be respectively: ammonium metavanadate 0.643g, cerium nitrate 5.047g, manganese acetate 2.819g, ferric nitrate 1.262g, tungsten Ammonium Acid 1.64g, Ammonium Molybdate 3.066g, Nano TiO 2 40g.

[0052] (3) WO 3 、MoO 3 cocatalyst and V 2 o 5 , CeO 2 , MnO 2 , Fe 2 o 3 Loading of main active ingredient

[0053] Weigh 1.64g ammonium tungstate and dissolve it in 307ml deionized water; then weigh 3.066g ammonium molybdate and dissolve it in 1000ml deionized water; weigh 2.5g polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com